- Joined

- Jun 12, 2014

- Messages

- 5,055

I was asked several weeks ago by a forum member to do a full turn-key VFD build for a 935 that he was planning on ordering. Normally I would decline to do these systems because of the time and complexity, but I have know this individual for a few years and had previously done a control system for his 1340GT lathe. The specifications where that the VFD enclosure would be mounted behind the mill and not directly attached to it. On my mill builds I use a larger metal enclosure which is 12x20x8, the volume being large enough that is does not require venting.

Additional features were momentary buttons for stop and run, forward/reverse rotary switch, auto-reverse triggered by the a proximity sensor, back gear proximity sensor to always maintain the same spindle direction, coolant switch that runs when the spindle is active, 1 and 2 stage braking (reverts to 1 stage for E-Stop), speed control, tachometer (with spindle pick-up), LED ram mounted spindle light ring and momentary snap action buttons for instantaneous spindle operation that can be used for tapping. We opted not to use a toggle switch/joystick as used on the lathe because the danger of accidentally knocking it. The low voltage relay control system is run by a 24VDC fused supply, and a separate fused 12VDC for the tach/LED light ring. There is also provisions for powering additional 12/24VDC systems such as solenoid coolant, other lights, and a separated 120/240VAC on e separate breaker for drives and DRO. The external control wiring uses custom made plug and socket shielded cables for the control pods. There are a few additional features and interlocks within the system, the build time was approximately 4 weeks after all the supplies were in house. All VFD system components are mounted to the back plate so it is removable with the sockets mounted from the rear (in the cabinet).

The speed control is a military grade 3 turn precision pot, the programming allows a speed range of 15-120Hz using the motor 4 pole (1750 RPM) base speed. The motor on the PM935 and the PM949 are the same, it is a 2 speed constant Hp 4 pole low speed and 2 pole high speed (3500 RPM). So there is no limitation in using the motor in its 4 pole setting and the performance of the mill will be better by over speeding the motor on the to 120Hz to give the same high speed range.

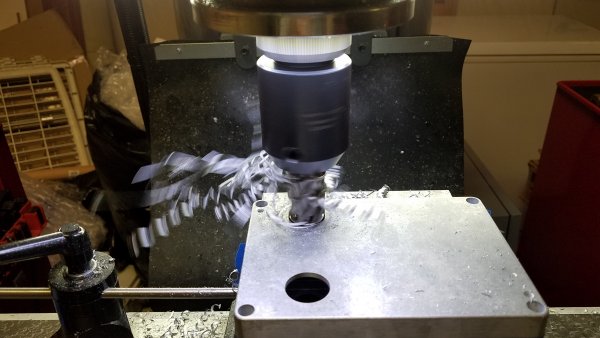

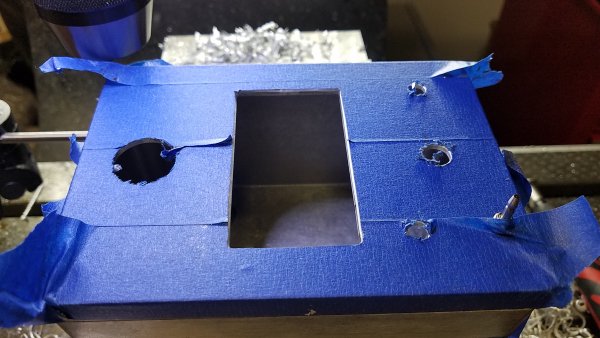

Turning the 100mm LED light ring holder, the tach sensor is 8mm diameter. Tolerance to dimensional drawings are -0.000 +0.001. I will post the drawing once I know that everything fits and works. With these smaller sensors, the distance between the sensor and the magnet needs to be ~0.050" for it to detect correctly. You also need to verify the polarity of the magnet and that the tach works correctly before it is installed. For some reason on the sensor the magnet orientation needed to be flipped after the install, not an easy task once it is pressed into the ring with Loctite. A small 8-32 SS set screw is used to lock the rings once mounted, the LED ring cover is a press fit to allow replacement, but can also be mounted with some silicone sealant.

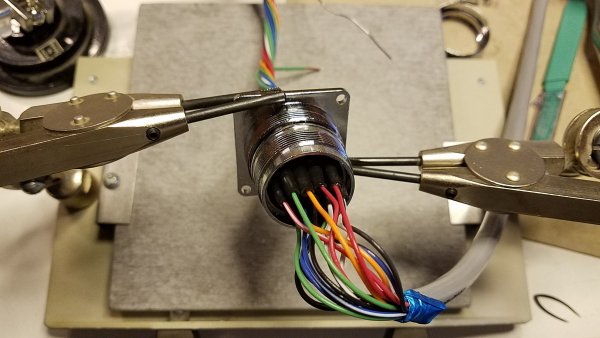

Preparing the cables, the upper control pod using a 16 pin socket, the lower is a 12 pin. Each pin soldered with a lead/tin/silver solder to assure good flow (unleaded solder is more prone to cold joints), fusing shrink tube is place over each pin and then an outer shrink tube binds all the wires.

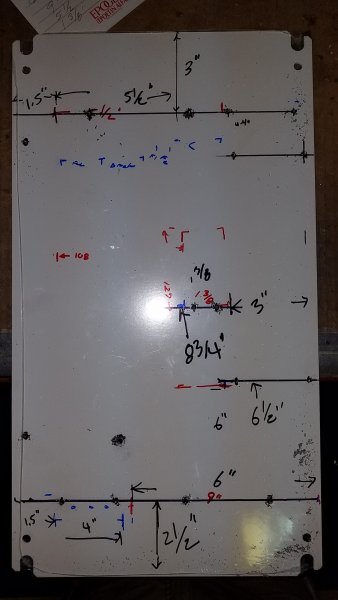

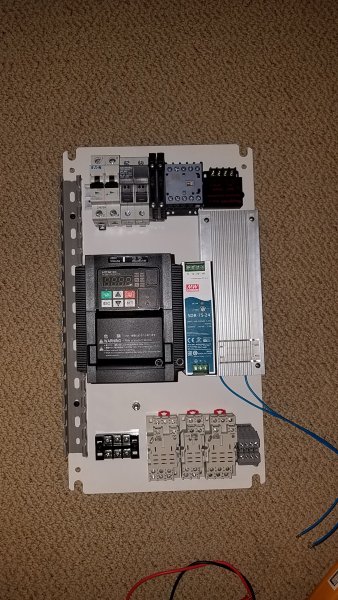

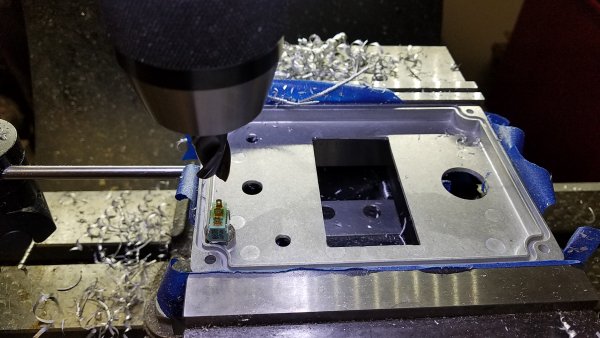

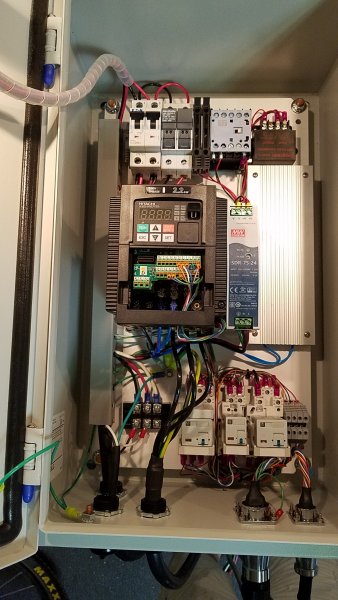

Initial layout of components on the back plate and drilling/tapping the holes, followed by component mounting. I use a star ground on all these types of builds via a threaded post through the back plate, then a star nut to lock. I also remove the paint around the bolt.

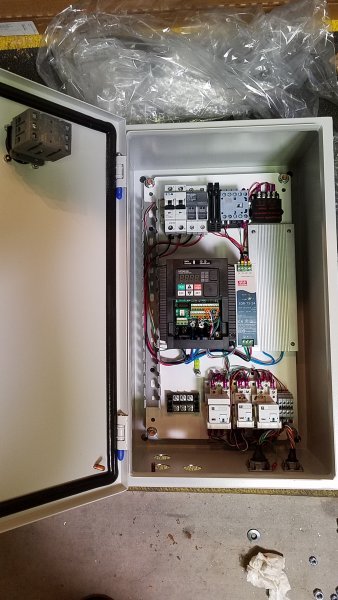

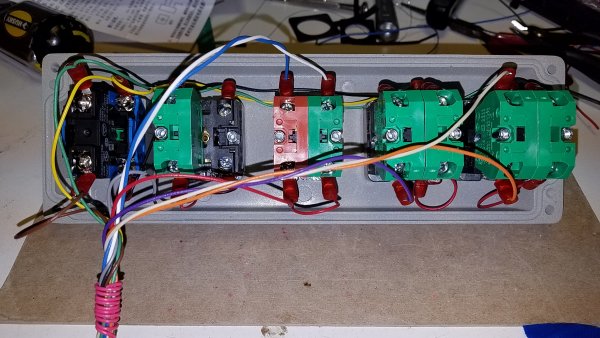

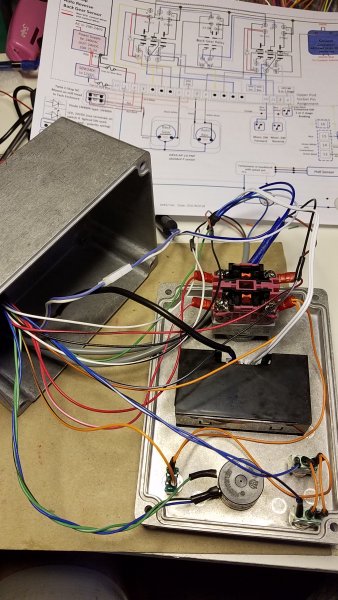

Wiring begins, all socket wiring is direct connections with the exception of interconnects between sockets that are connected at the gray terminal blocks. My total workspace for the wiring is a small 3x4' table so it can get messy.

Building/wiring the control pods.

Wiring the upper pod, both the LED ring and tach connections are plug and socket.

Powering up the system for VFD programming and testing the VFD with the motor connected.

The LED light rings are quite bright and they attach to the ram so move up and down with it so one does not get shadowing. The red and black buttons are the momentary spindle buttons with the black being down (right hand) and red reverse up (left hand). The right toggle is the 1 stage (1.2 seconds) and 2 stage (3 seconds) braking. E-Stop breaks both power to the control relays and P24 for the VFD inputs. The back gear sensor and auto reverse sensor are the small square sensors. The auto reverse can be used for right hand or left hand threading, essentially it reverse whatever the spindle direction is when triggered. It is reset when the stop button is pressed.

Hopefully the system will ship out next week, a lot of planning and time goes into these builds. Hopefully it will be a long time before I commit to another system like this.

Cheers,

Mark

Additional features were momentary buttons for stop and run, forward/reverse rotary switch, auto-reverse triggered by the a proximity sensor, back gear proximity sensor to always maintain the same spindle direction, coolant switch that runs when the spindle is active, 1 and 2 stage braking (reverts to 1 stage for E-Stop), speed control, tachometer (with spindle pick-up), LED ram mounted spindle light ring and momentary snap action buttons for instantaneous spindle operation that can be used for tapping. We opted not to use a toggle switch/joystick as used on the lathe because the danger of accidentally knocking it. The low voltage relay control system is run by a 24VDC fused supply, and a separate fused 12VDC for the tach/LED light ring. There is also provisions for powering additional 12/24VDC systems such as solenoid coolant, other lights, and a separated 120/240VAC on e separate breaker for drives and DRO. The external control wiring uses custom made plug and socket shielded cables for the control pods. There are a few additional features and interlocks within the system, the build time was approximately 4 weeks after all the supplies were in house. All VFD system components are mounted to the back plate so it is removable with the sockets mounted from the rear (in the cabinet).

The speed control is a military grade 3 turn precision pot, the programming allows a speed range of 15-120Hz using the motor 4 pole (1750 RPM) base speed. The motor on the PM935 and the PM949 are the same, it is a 2 speed constant Hp 4 pole low speed and 2 pole high speed (3500 RPM). So there is no limitation in using the motor in its 4 pole setting and the performance of the mill will be better by over speeding the motor on the to 120Hz to give the same high speed range.

Turning the 100mm LED light ring holder, the tach sensor is 8mm diameter. Tolerance to dimensional drawings are -0.000 +0.001. I will post the drawing once I know that everything fits and works. With these smaller sensors, the distance between the sensor and the magnet needs to be ~0.050" for it to detect correctly. You also need to verify the polarity of the magnet and that the tach works correctly before it is installed. For some reason on the sensor the magnet orientation needed to be flipped after the install, not an easy task once it is pressed into the ring with Loctite. A small 8-32 SS set screw is used to lock the rings once mounted, the LED ring cover is a press fit to allow replacement, but can also be mounted with some silicone sealant.

Preparing the cables, the upper control pod using a 16 pin socket, the lower is a 12 pin. Each pin soldered with a lead/tin/silver solder to assure good flow (unleaded solder is more prone to cold joints), fusing shrink tube is place over each pin and then an outer shrink tube binds all the wires.

Initial layout of components on the back plate and drilling/tapping the holes, followed by component mounting. I use a star ground on all these types of builds via a threaded post through the back plate, then a star nut to lock. I also remove the paint around the bolt.

Wiring begins, all socket wiring is direct connections with the exception of interconnects between sockets that are connected at the gray terminal blocks. My total workspace for the wiring is a small 3x4' table so it can get messy.

Building/wiring the control pods.

Wiring the upper pod, both the LED ring and tach connections are plug and socket.

Powering up the system for VFD programming and testing the VFD with the motor connected.

The LED light rings are quite bright and they attach to the ram so move up and down with it so one does not get shadowing. The red and black buttons are the momentary spindle buttons with the black being down (right hand) and red reverse up (left hand). The right toggle is the 1 stage (1.2 seconds) and 2 stage (3 seconds) braking. E-Stop breaks both power to the control relays and P24 for the VFD inputs. The back gear sensor and auto reverse sensor are the small square sensors. The auto reverse can be used for right hand or left hand threading, essentially it reverse whatever the spindle direction is when triggered. It is reset when the stop button is pressed.

Hopefully the system will ship out next week, a lot of planning and time goes into these builds. Hopefully it will be a long time before I commit to another system like this.

Cheers,

Mark

Last edited: