- Joined

- May 29, 2014

- Messages

- 188

Hello group. I haven't posted in quite a while; however, I read most of the posts here daily.

I have a PM932PDF mill that I am in the formative stages of getting ready to think about upgrading the motor to 3 phase with a VFD.

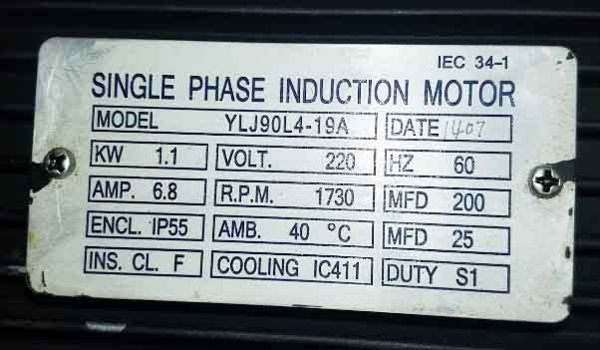

I figured the best place to start would be with the motor. Below is a pic of the data plate on the side of the existing motor.

I have unsuccessfully Googled the model number (and several variations of it) and have located nothing in English that I can use.

If anyone out there has any info about a 3 phase motor that will fit this mill, I would be grateful if you could pass it on to me.

I have not pestered Matt, yet. He will be the next source if no one on the forum has any info.

Thanks a bunch,

Jerry in Delaware

I have a PM932PDF mill that I am in the formative stages of getting ready to think about upgrading the motor to 3 phase with a VFD.

I figured the best place to start would be with the motor. Below is a pic of the data plate on the side of the existing motor.

I have unsuccessfully Googled the model number (and several variations of it) and have located nothing in English that I can use.

If anyone out there has any info about a 3 phase motor that will fit this mill, I would be grateful if you could pass it on to me.

I have not pestered Matt, yet. He will be the next source if no one on the forum has any info.

Thanks a bunch,

Jerry in Delaware