-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pm835s spindle

- Thread starter Batmanacw

- Start date

Nevermind. I checked the run out and it's with 0.0001" on the taper. I pushed up on the spindle and it moves 0.0003", exactly the same as if I push on the whole head.

I just wanted to be sure the slight imperfections in my fly cutter cuts were in the rigidity of the machine itself and not in the spindle.

These J head mills are not hyper ridgid but they are versatile.

I just wanted to be sure the slight imperfections in my fly cutter cuts were in the rigidity of the machine itself and not in the spindle.

These J head mills are not hyper ridgid but they are versatile.

- Joined

- Jun 12, 2014

- Messages

- 5,056

You will probably get that degree of movement in most knee mills, mass does help to decrease the flex/dampen vibration, and also centrifugal force of running a balance cutter at higher RPM. Adding either flood coolant or a mist/drip type system can improve surface finish. Old thread on the subject of fly-cutters and balance issues and surface finish issues.

www.hobby-machinist.com

www.hobby-machinist.com

In aluminum I run a 4" face mill with 7 inserts typically at 2800 RPM with an 8-10 IPM and get very smooth finishes, this is just for sizing and the finish improves when I run a air/coolant system. The knee mill is around 2800 lbs. You can run a balanced head at much higher RPM (cuts/inch) but requires the right insert geometry as well as quality of the head to assure they are all cutting at the same height.

Flycutter Balance Problem / Question

I have a Suburban Fly cutter and their 5" bar . I started getting familiar with it by facing off all my aluminum chill blocks. Roughly 4"x5" one inch thick 6061 blocks . The fly cutter works great but I have to run it in low range in my mill, which is 370 RPM and slow table feed . I can run it...

www.hobby-machinist.com

www.hobby-machinist.com

In aluminum I run a 4" face mill with 7 inserts typically at 2800 RPM with an 8-10 IPM and get very smooth finishes, this is just for sizing and the finish improves when I run a air/coolant system. The knee mill is around 2800 lbs. You can run a balanced head at much higher RPM (cuts/inch) but requires the right insert geometry as well as quality of the head to assure they are all cutting at the same height.

Flycutters tend to magnify issues with your mills tram. The bigger the flycutters radius, the more pronounced the effect. Is the minor issue your having related to surface finish?

In the very slight back drag of the fly cutter you can see slight inconsistent imperfections in the tool marks. It back drags very slightly in both directions but slightly less in one direction. I've never saw a mill that didn't.

It's not really a problem but I wanted to be sure I wasn't running my spindle too loose.

I've been lucky that my tram is staying very accurate. There is flex in the top assembly but I've read that is pretty normal.

- Joined

- Jan 6, 2017

- Messages

- 1,248

There is flex in the top assembly but I've read that is pretty normal.

My PM935 has about the same.

When checking bearings, you can mount the magnetic base to the head, near the spindle and eliminate the flex from your measurements.

Same on a lathe.

You will probably get that degree of movement in most knee mills, mass does help to decrease the flex/dampen vibration, and also centrifugal force of running a balance cutter at higher RPM. Adding either flood coolant or a mist/drip type system can improve surface finish. Old thread on the subject of fly-cutters and balance issues and surface finish issues.

Flycutter Balance Problem / Question

I have a Suburban Fly cutter and their 5" bar . I started getting familiar with it by facing off all my aluminum chill blocks. Roughly 4"x5" one inch thick 6061 blocks . The fly cutter works great but I have to run it in low range in my mill, which is 370 RPM and slow table feed . I can run it...www.hobby-machinist.com

In aluminum I run a 4" face mill with 7 inserts typically at 2800 RPM with an 8-10 IPM and get very smooth finishes, this is just for sizing and the finish improves when I run a air/coolant system. The knee mill is around 2800 lbs. You can run a balanced head at much higher RPM (cuts/inch) but requires the right insert geometry as well as quality of the head to assure they are all cutting at the same height.

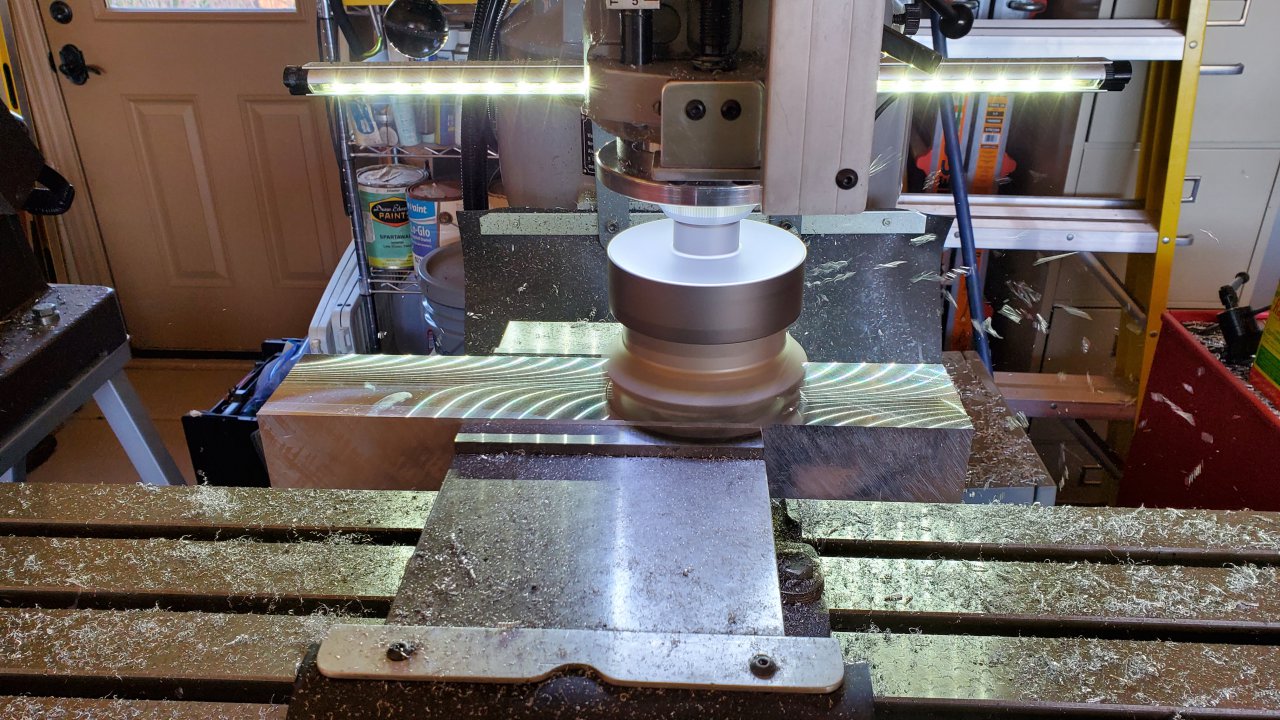

View attachment 389072

View attachment 389076

I never run a face mill bigger than 2". I've done fine with them. My mill isn't more than 1700 lbs. Pretty small and not a ridgid monster. I still do plenty if good work, just not as fast. Lol.

- Joined

- Oct 24, 2013

- Messages

- 485

That's a sweet cutter!You will probably get that degree of movement in most knee mills, mass does help to decrease the flex/dampen vibration, and also centrifugal force of running a balance cutter at higher RPM. Adding either flood coolant or a mist/drip type system can improve surface finish. Old thread on the subject of fly-cutters and balance issues and surface finish issues.

Flycutter Balance Problem / Question

I have a Suburban Fly cutter and their 5" bar . I started getting familiar with it by facing off all my aluminum chill blocks. Roughly 4"x5" one inch thick 6061 blocks . The fly cutter works great but I have to run it in low range in my mill, which is 370 RPM and slow table feed . I can run it...www.hobby-machinist.com

In aluminum I run a 4" face mill with 7 inserts typically at 2800 RPM with an 8-10 IPM and get very smooth finishes, this is just for sizing and the finish improves when I run a air/coolant system. The knee mill is around 2800 lbs. You can run a balanced head at much higher RPM (cuts/inch) but requires the right insert geometry as well as quality of the head to assure they are all cutting at the same height.

View attachment 389072

View attachment 389076