- Joined

- Mar 22, 2017

- Messages

- 57

Greetings,

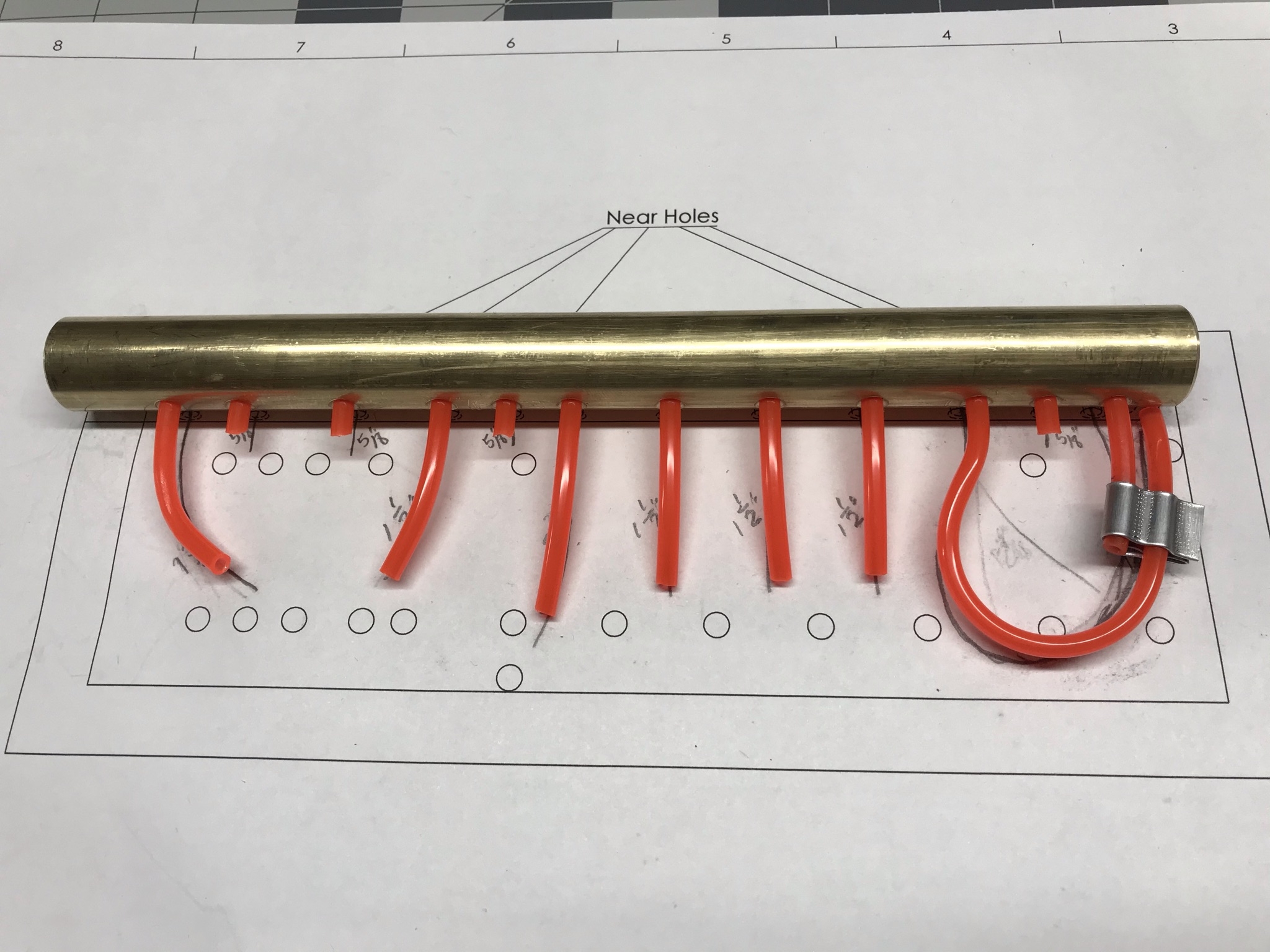

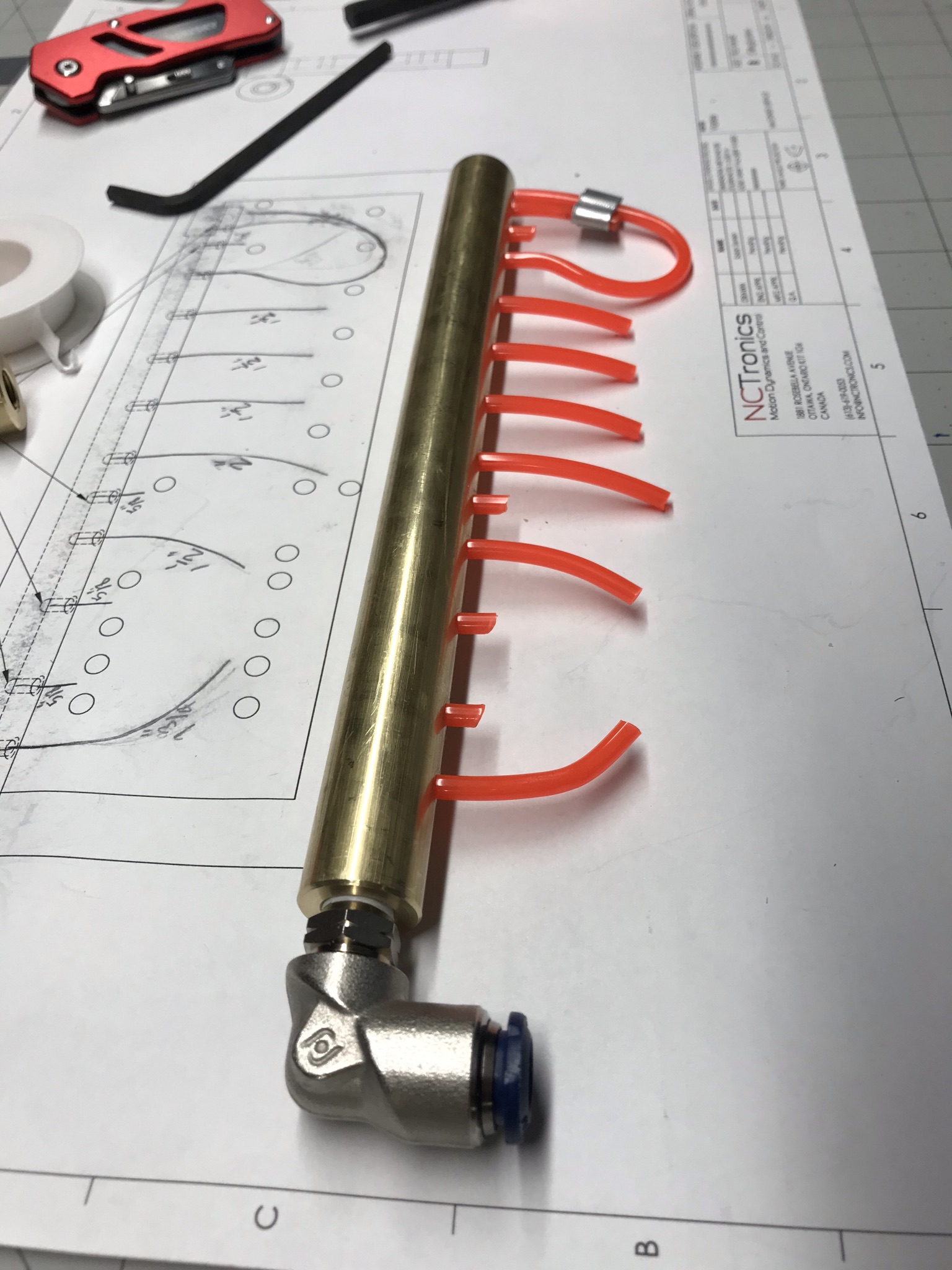

I have finished the lubrication manifold for my PM1340 Lathe. Below are some photos for those that might be interested.

I drilled and tapped 8-32 holes into the brass manifold. The polyurethane tubing (4mm-5/32") self-screws into these holes. I used a heat gun to shape the tubes into the bends I needed for each station.

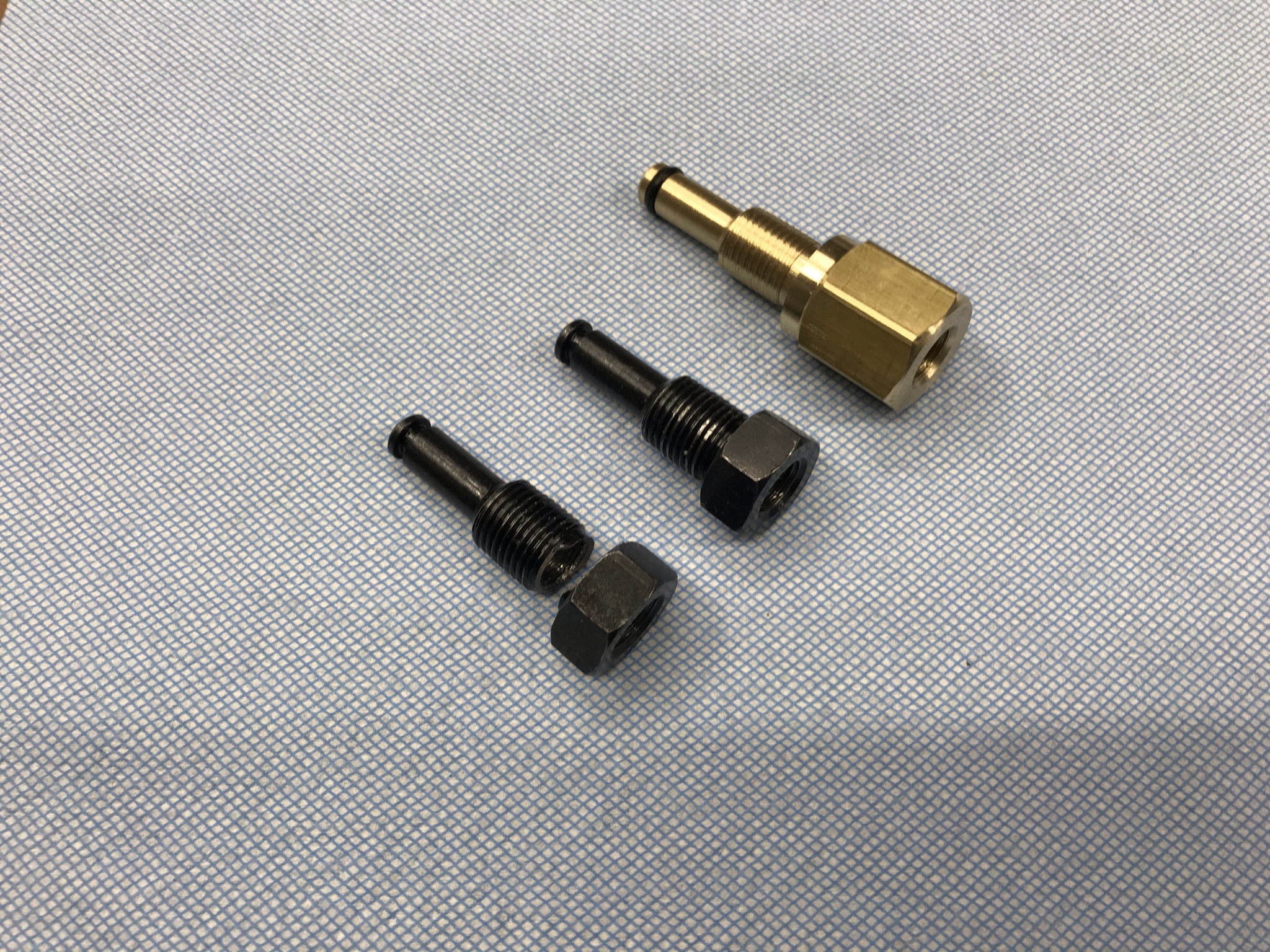

I am using a KBC tools one-shot oiler. I wanted to go to 1/8"-NPT PTC fittings. When I drilled the fitting that I removed from the oiler for 1/8"-NPT the wall became too thin and the fitting broke as I tightened it back into the body of the oiler. So, I made 2 new fittings from brass. Note that these fittings had a one-way valve (a steel ball with a spring) that came out during the drilling. I had already planned on a one-way valve in-line anyways, so that did not matter.

Here's a short clip of the manifold squirting oil on top of the gearbox.

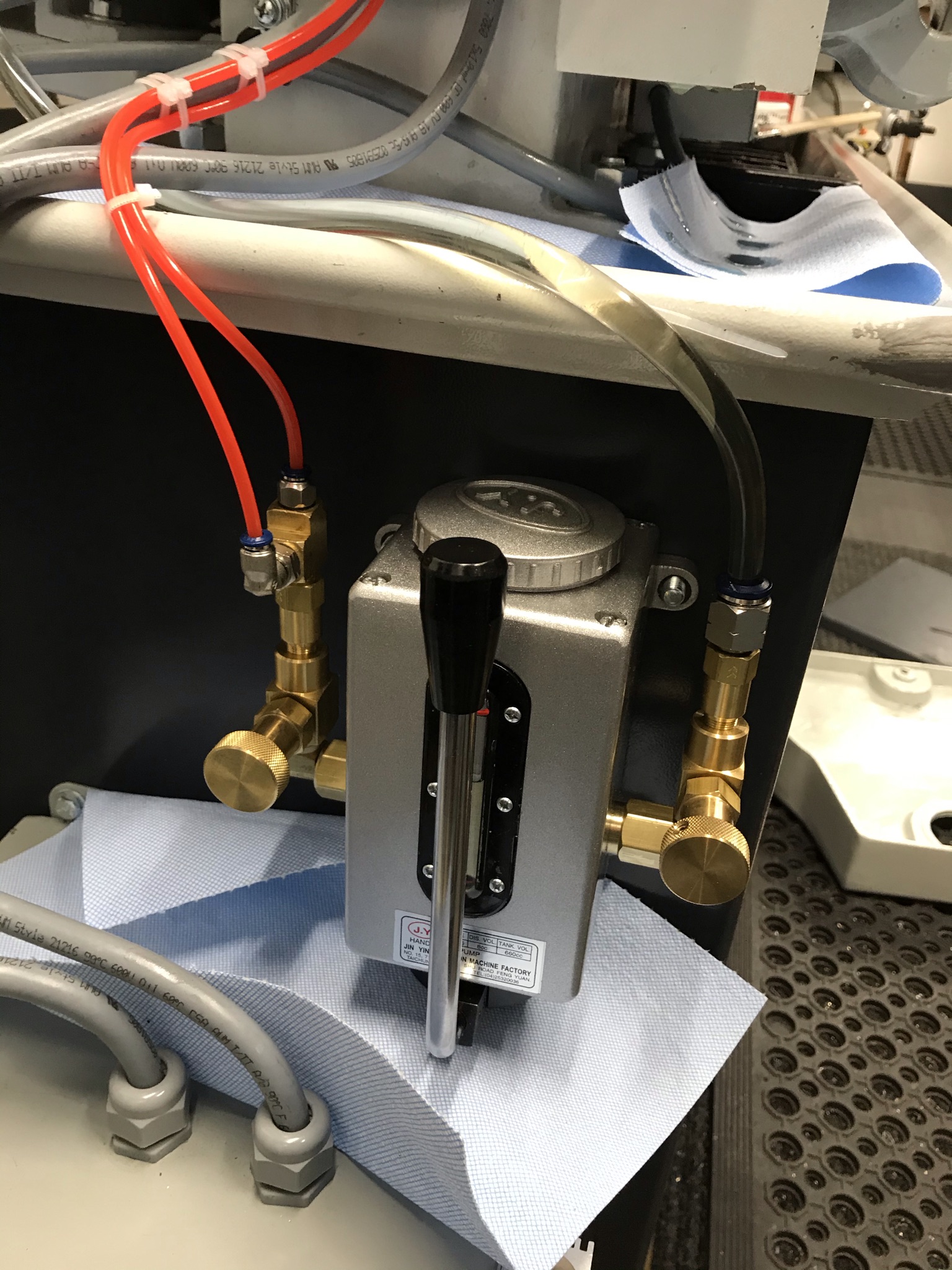

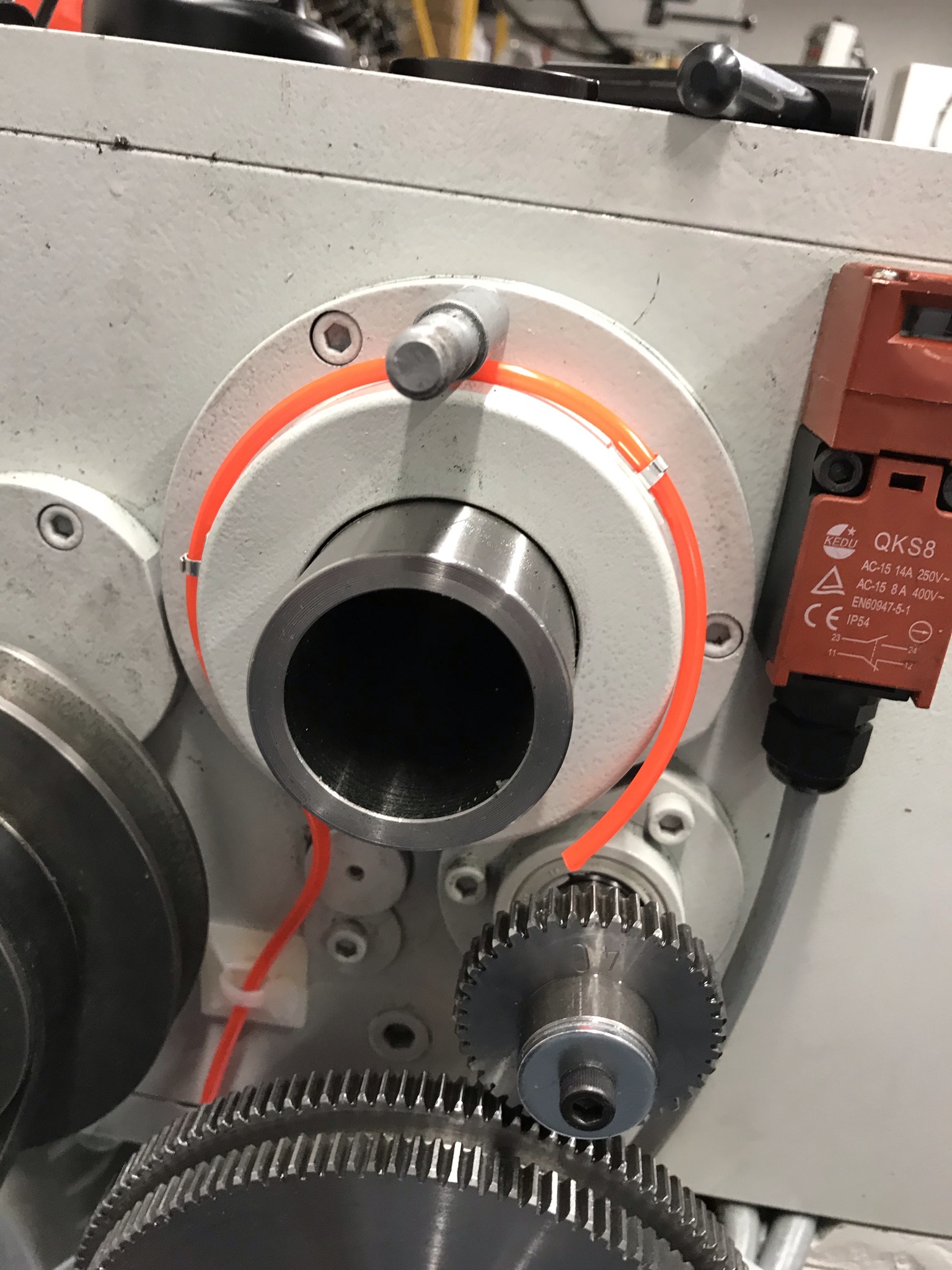

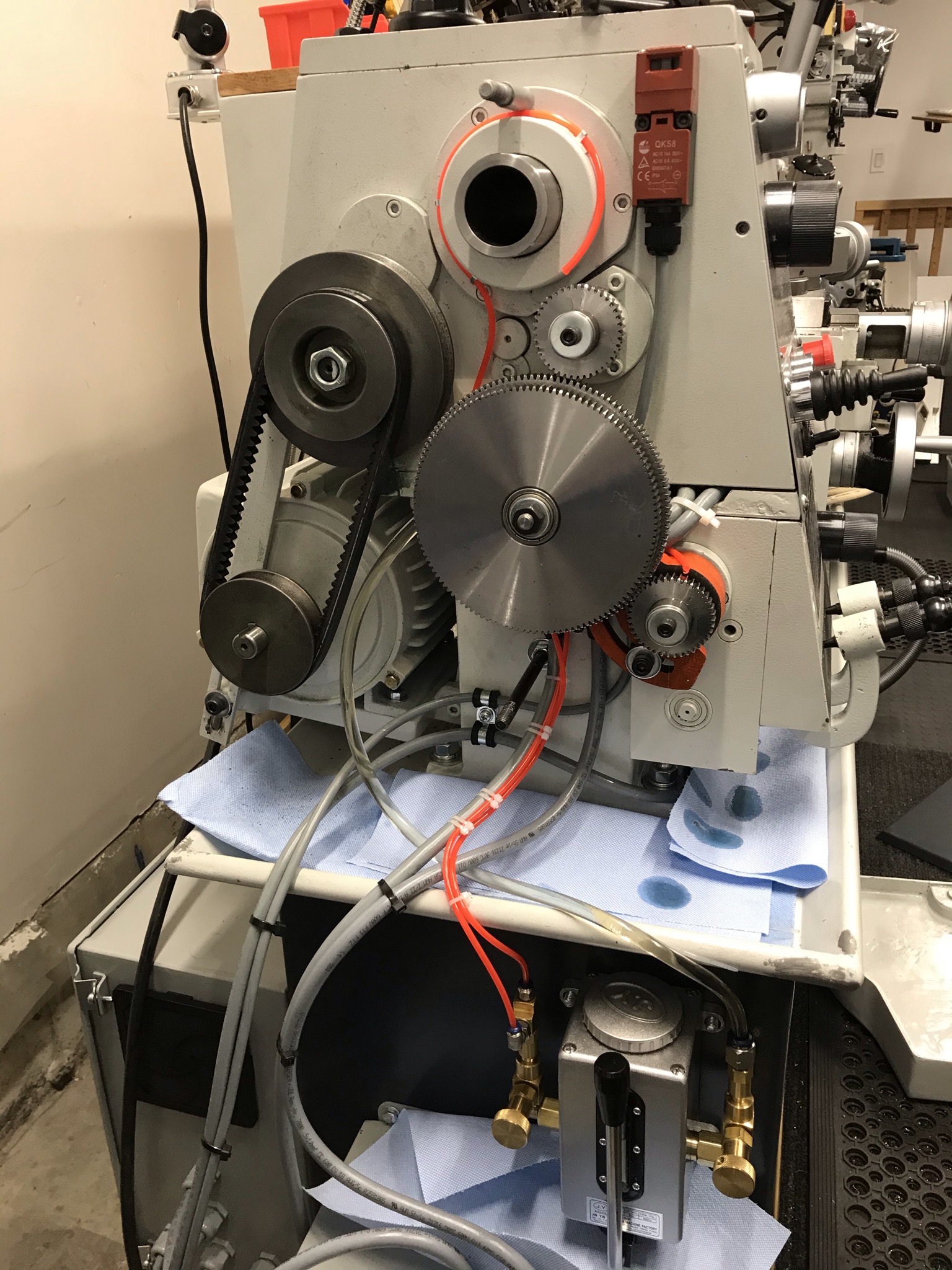

The oiler had two outputs. I used one to feed two lines to oil the gears in the back of the lathe. The other output is dedicated to the manifold. See photo below.

Here you see the tubes going to the gear train in the back of the lathe. There are two flow control valves for each line as well as two one-way valves.

Here's a photo with the cover on.

Hope this helps someone.

Salah

I have finished the lubrication manifold for my PM1340 Lathe. Below are some photos for those that might be interested.

I drilled and tapped 8-32 holes into the brass manifold. The polyurethane tubing (4mm-5/32") self-screws into these holes. I used a heat gun to shape the tubes into the bends I needed for each station.

I am using a KBC tools one-shot oiler. I wanted to go to 1/8"-NPT PTC fittings. When I drilled the fitting that I removed from the oiler for 1/8"-NPT the wall became too thin and the fitting broke as I tightened it back into the body of the oiler. So, I made 2 new fittings from brass. Note that these fittings had a one-way valve (a steel ball with a spring) that came out during the drilling. I had already planned on a one-way valve in-line anyways, so that did not matter.

Here's a short clip of the manifold squirting oil on top of the gearbox.

The oiler had two outputs. I used one to feed two lines to oil the gears in the back of the lathe. The other output is dedicated to the manifold. See photo below.

Here you see the tubes going to the gear train in the back of the lathe. There are two flow control valves for each line as well as two one-way valves.

Here's a photo with the cover on.

Hope this helps someone.

Salah

Last edited: