- Joined

- Jun 12, 2014

- Messages

- 5,055

The PM1340GT is very nicely built, works very well, and I have very few bones to pick with its features and overall quality. One area that did concern me when I was revising the front control switches, was the oiler system for the open Norton style gearbox. The current system (which is probably similar to other lathes with open gearboxes) has a single lubrication hole just above the gearbox on the right side of the lathe. When I pumped oil into the hole and checked the distribution, only the right side of the gearbox dripped oil onto the gears. So I also used a long nose oiler can from underneath the gearbox to get oil to the left side of the gearbox.

I like to tinker, so I though of various ways and schemes to get a more even oil distribution to the 15+ drip holes that are on top of the gearbox. I had thought of milling a new spacer plate that sits on top of the oil holes and drilling multiple oiler outlets, but it would have interfered with my switches and wiring. I ended up with a much simpler method, which is using hard aluminum 4mm tubing (could also use steel or copper) bent to fit underneath the cover plate as shown in the pictures. There is about a 6mm gap above the oil drip holes that are on top of the gearbox where one can route the tubing. A 4 tube oil distribution block and 4 separate tubes were routed and positioned so that the expanding oiled areas covered the whole oil trough area, as one can see by the expanding oil saturation areas in the picture. Three to four stokes from the pump was sufficient to supply oil to all the gearbox oil drip holes. It is very simple to use and very easy to give a few pumps prior to the start of machining on a regular bases. I used a fine tooth hacksaw to cut the 4mm aluminum tubing and then cleaned and drilled the tubing holes out with a small drill. I use a drip pan under the gears, but plan to make a fitted plastic catch basin. I like the ease and selection from the open type gearbox, dislike the mess and difficulty changing the gear selectors.

This oil system should also be applicable to other lathes with open gearboxes providing there is clearance to run the oil tubes. An alternative (if you have the room) would be to use 4mm tubing to pipe elbows tapped into a plate.

Patrs and approximate cost

CTA-8 Type Hand-Pull (Left) Manual Lubricators $45

CB TYPE Anti-Vibration Distributor With Nut CB-4 $8.60

(must specify CTA-8 outlet and CB-4 inlet are to be the same 4mm)

Part #: Aluminum Pipe 4mm for Lubrication System 10 feet $15

Part # PPST30 20" High Pressure Flexible Hose (500mm) for Lubrication System 4mm Bijur to connect between the pump and the distribution block (disribution block must use 4mm inlet as opposed to default which is 6mm). $10

Distribution block was mounted with 5mm x 16mm Allen cap screws, CTA-8 with 6mm x 16mm

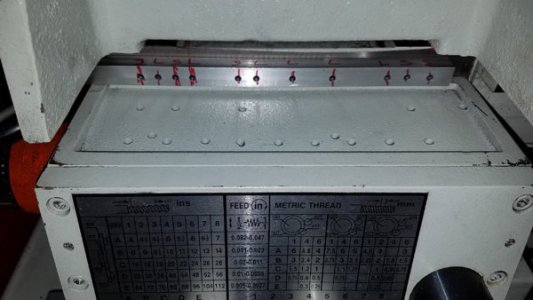

Placement of oil tubes with oil being pumped, and cover plate on top of tubes.

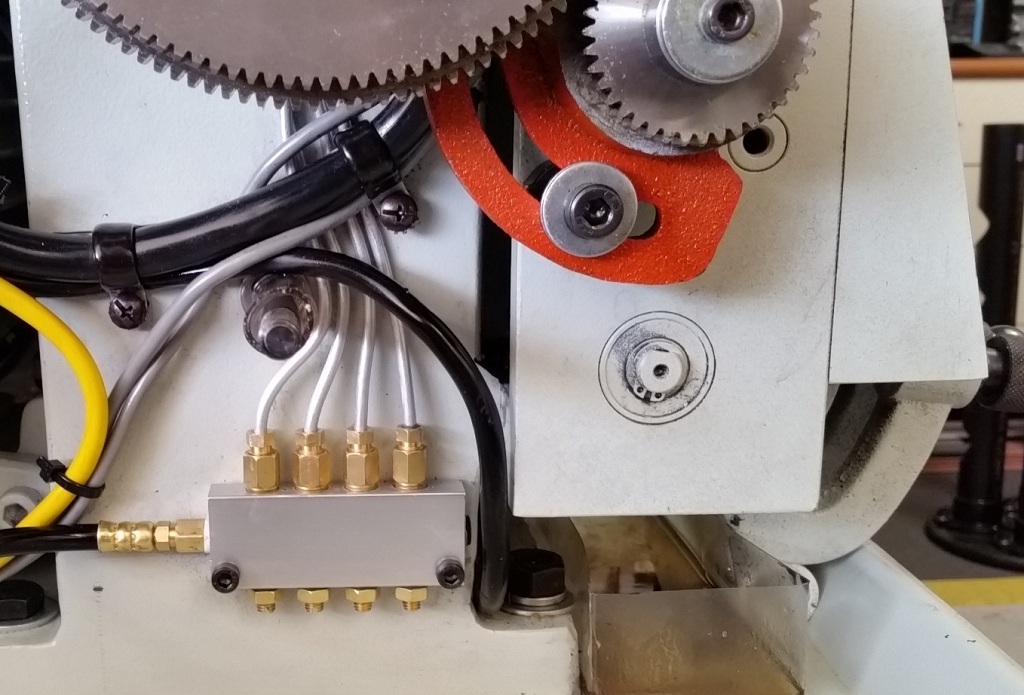

Four tube oil distribution block.

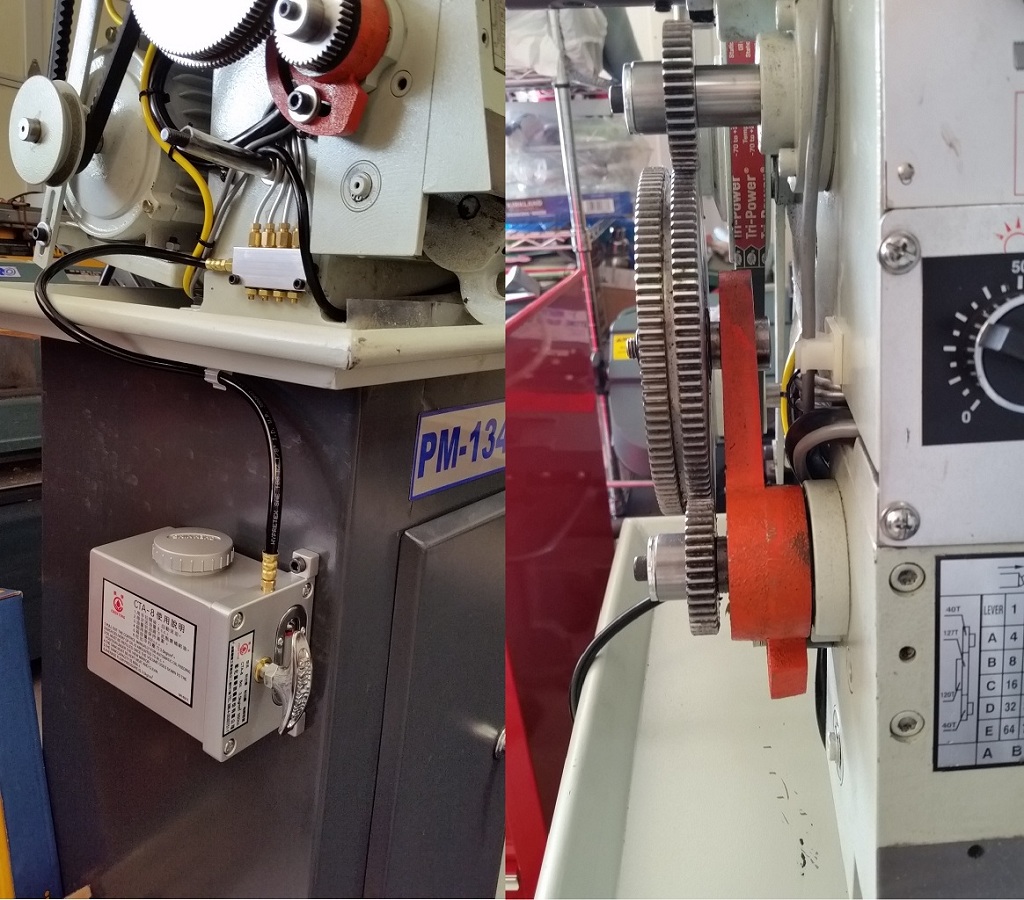

Pump oiler and clearance

Finished

I like to tinker, so I though of various ways and schemes to get a more even oil distribution to the 15+ drip holes that are on top of the gearbox. I had thought of milling a new spacer plate that sits on top of the oil holes and drilling multiple oiler outlets, but it would have interfered with my switches and wiring. I ended up with a much simpler method, which is using hard aluminum 4mm tubing (could also use steel or copper) bent to fit underneath the cover plate as shown in the pictures. There is about a 6mm gap above the oil drip holes that are on top of the gearbox where one can route the tubing. A 4 tube oil distribution block and 4 separate tubes were routed and positioned so that the expanding oiled areas covered the whole oil trough area, as one can see by the expanding oil saturation areas in the picture. Three to four stokes from the pump was sufficient to supply oil to all the gearbox oil drip holes. It is very simple to use and very easy to give a few pumps prior to the start of machining on a regular bases. I used a fine tooth hacksaw to cut the 4mm aluminum tubing and then cleaned and drilled the tubing holes out with a small drill. I use a drip pan under the gears, but plan to make a fitted plastic catch basin. I like the ease and selection from the open type gearbox, dislike the mess and difficulty changing the gear selectors.

This oil system should also be applicable to other lathes with open gearboxes providing there is clearance to run the oil tubes. An alternative (if you have the room) would be to use 4mm tubing to pipe elbows tapped into a plate.

Patrs and approximate cost

CTA-8 Type Hand-Pull (Left) Manual Lubricators $45

CB TYPE Anti-Vibration Distributor With Nut CB-4 $8.60

(must specify CTA-8 outlet and CB-4 inlet are to be the same 4mm)

Part #: Aluminum Pipe 4mm for Lubrication System 10 feet $15

Part # PPST30 20" High Pressure Flexible Hose (500mm) for Lubrication System 4mm Bijur to connect between the pump and the distribution block (disribution block must use 4mm inlet as opposed to default which is 6mm). $10

Distribution block was mounted with 5mm x 16mm Allen cap screws, CTA-8 with 6mm x 16mm

Placement of oil tubes with oil being pumped, and cover plate on top of tubes.

Four tube oil distribution block.

Pump oiler and clearance

Finished