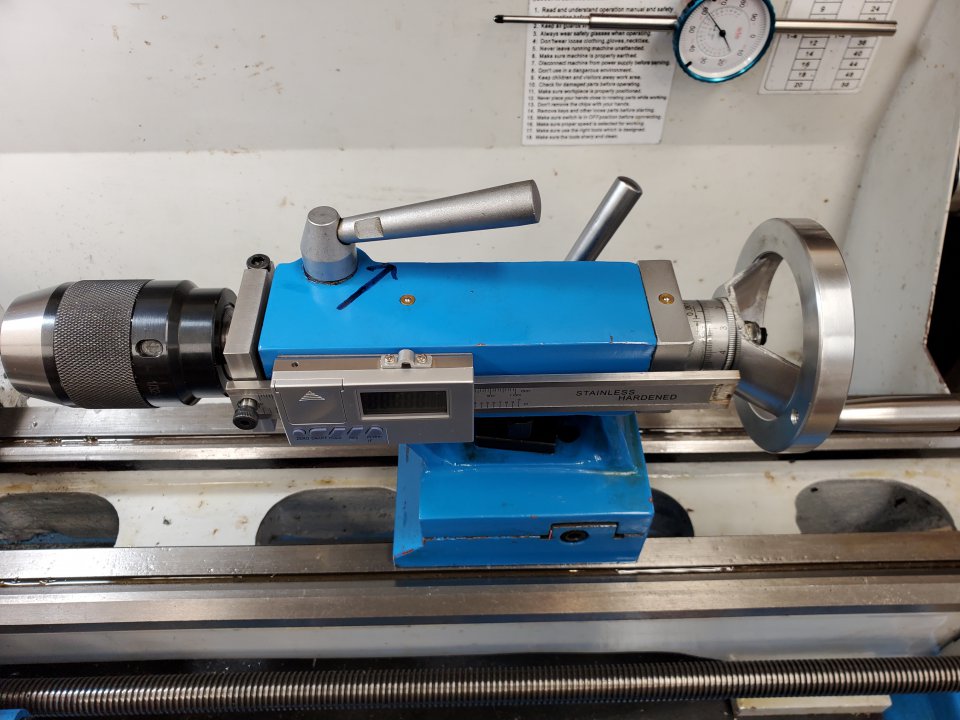

PM1030V tail stock digital read out.

I originally set up a 1" dial indicator and a little clamp I made for it to read against.

Eventually I bought a 2" travel indicator and that seemed like the cats pajamas but I kept bumping it and the rod would fly to its stop and the gear rack would skip a tooth. Then you end up not starting on zero with a proper amount of preload.

This led to buying a Shars 4" digital read out.

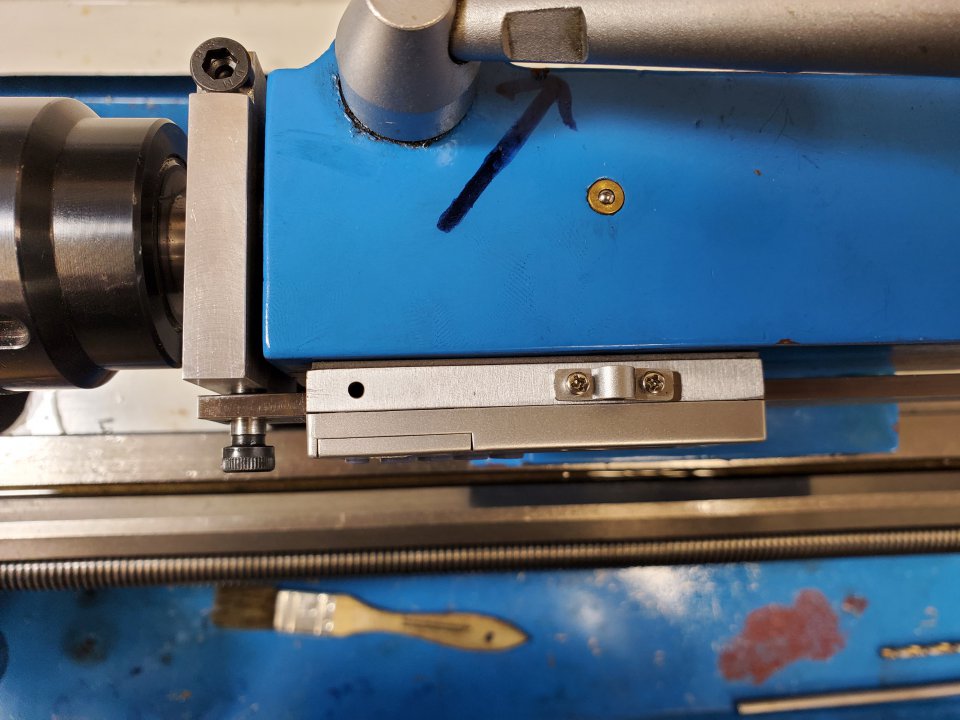

The tail stock isn't big enough to attach on top and that would have covered my oiling point. That is why I mounted it on the front.

The side of the casting is not dead flat so I used a shoulder bolt to hold the end of the slide. I drilled and reamed the extremely hard slide for a close fit but still able to allow movement.

I decided to try gorilla double stick tape for now. I cleaned the paint with acetone so the tape could get a good bite. Once it fails I'll make a plate and drill and tap the side of the tailstock. Since the side is not flat I'll most likely just use a single screw so the body can rotate a bit if it needs to.

The slide had to be shortened to be useful. I suggest cooling the slide constantly as you cut it off. It blistered the plastic and glass scale material a bit. I'd cut through the scale side first.

Now it is attached and not easily removed I'm pretty sure that won't bother me too much. Now I don't have to worry about damaging the 2" indicator or about sliding the indicator to zero.

I originally set up a 1" dial indicator and a little clamp I made for it to read against.

Eventually I bought a 2" travel indicator and that seemed like the cats pajamas but I kept bumping it and the rod would fly to its stop and the gear rack would skip a tooth. Then you end up not starting on zero with a proper amount of preload.

This led to buying a Shars 4" digital read out.

The tail stock isn't big enough to attach on top and that would have covered my oiling point. That is why I mounted it on the front.

The side of the casting is not dead flat so I used a shoulder bolt to hold the end of the slide. I drilled and reamed the extremely hard slide for a close fit but still able to allow movement.

I decided to try gorilla double stick tape for now. I cleaned the paint with acetone so the tape could get a good bite. Once it fails I'll make a plate and drill and tap the side of the tailstock. Since the side is not flat I'll most likely just use a single screw so the body can rotate a bit if it needs to.

The slide had to be shortened to be useful. I suggest cooling the slide constantly as you cut it off. It blistered the plastic and glass scale material a bit. I'd cut through the scale side first.

Now it is attached and not easily removed I'm pretty sure that won't bother me too much. Now I don't have to worry about damaging the 2" indicator or about sliding the indicator to zero.