If you own a PM1030V or PM1022V you will want to see this.

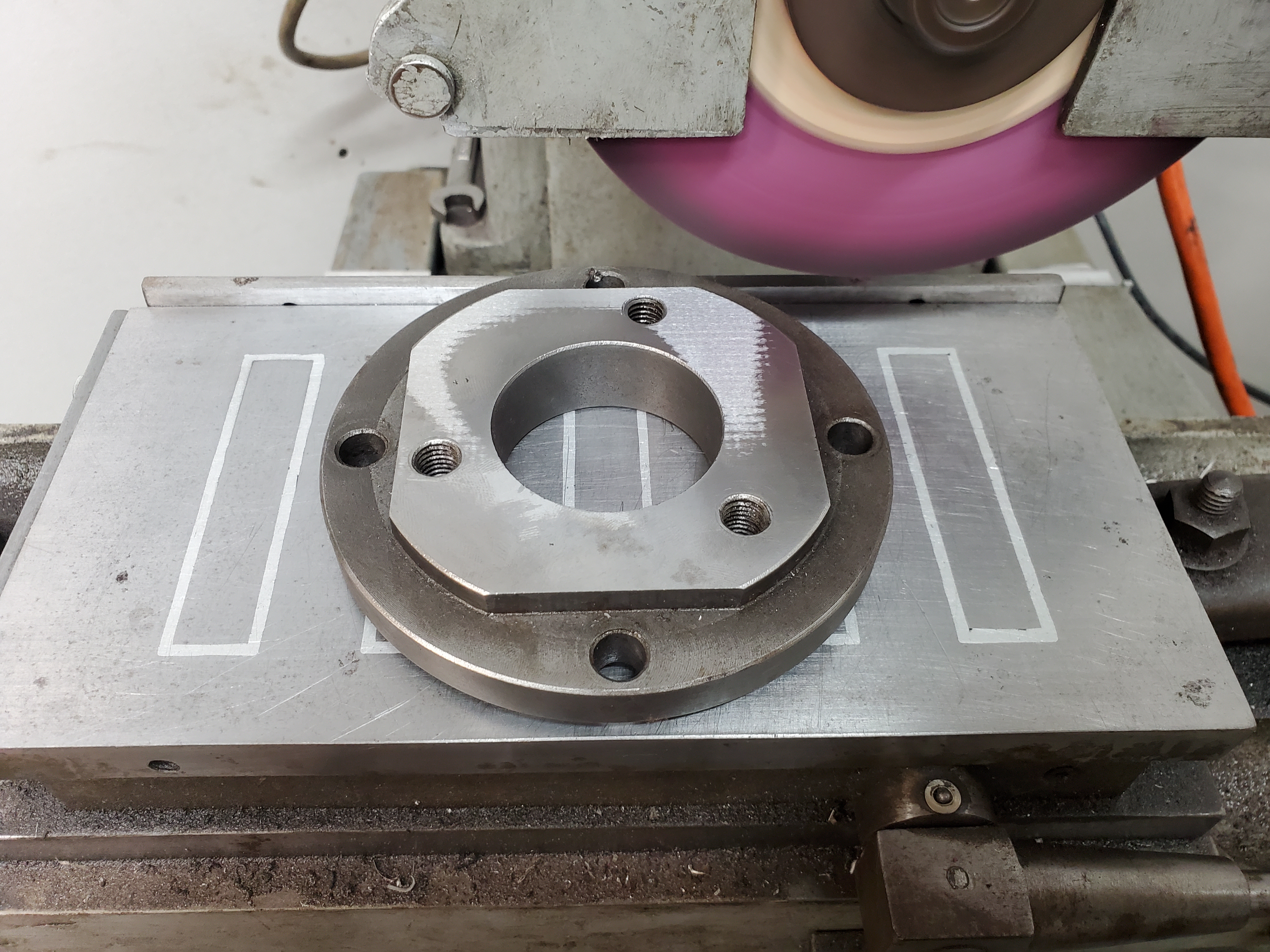

The adapter plates on the 3 and 4 jaw chucks are not flat. Mine were 0.002" to 0.004" out of flat.

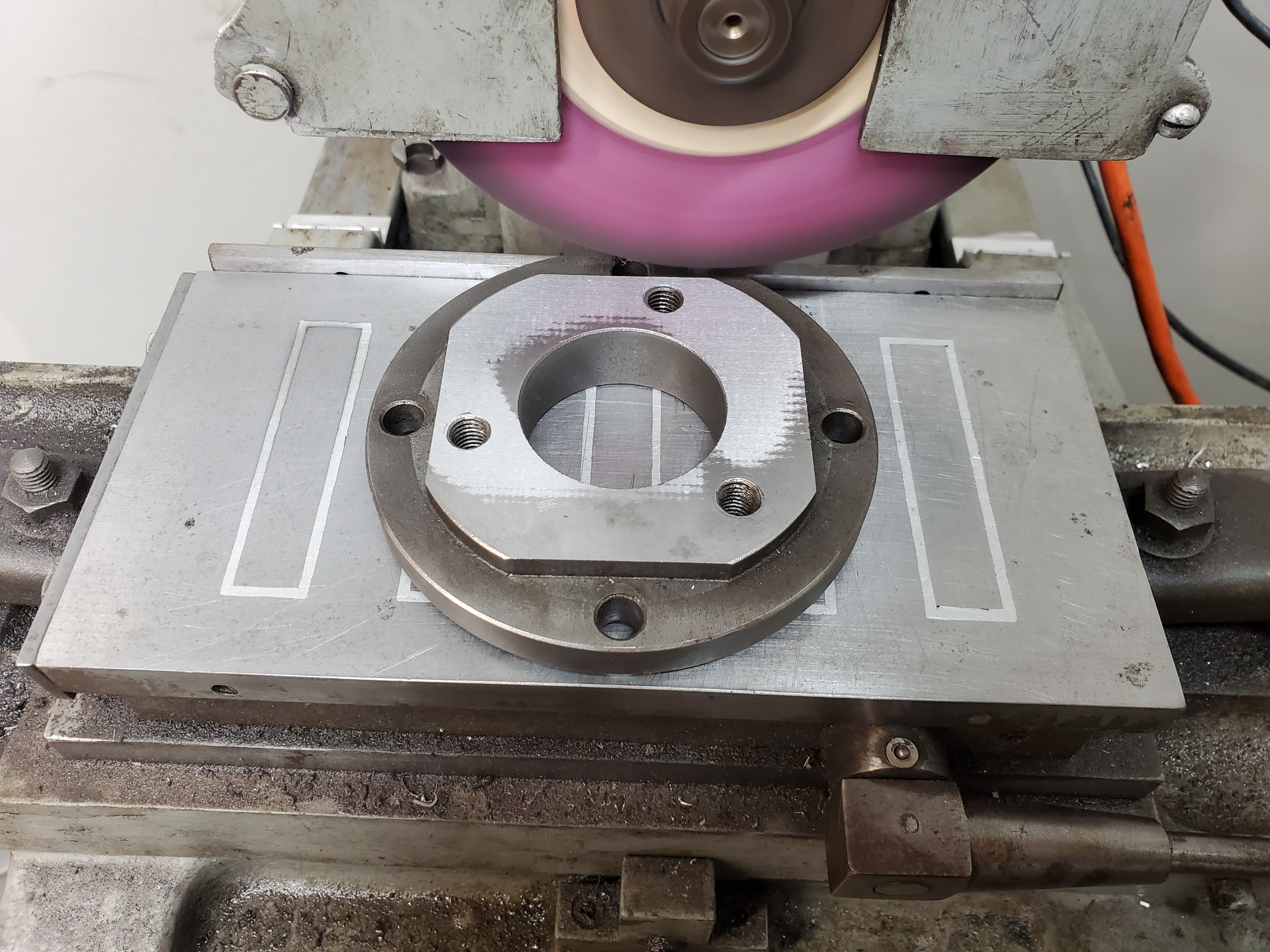

These pictures show the bright areas where I lapped both sides to see where it was touching.

Spindle side.

Side toward the chuck.

I suggest you consider surface grinding and lapping it in, or just lapping the mating surface of the adapter that sits against the spindle nose.

On the lathe I turned the flat face surrounding the spindle nose because it was 0.004" off perpendicular to the spindle nose, which had no run-out. The flat part was dished in the center so it showed little run-out but it wasn't flat. I didn't show this here as I fixed it a few months ago.

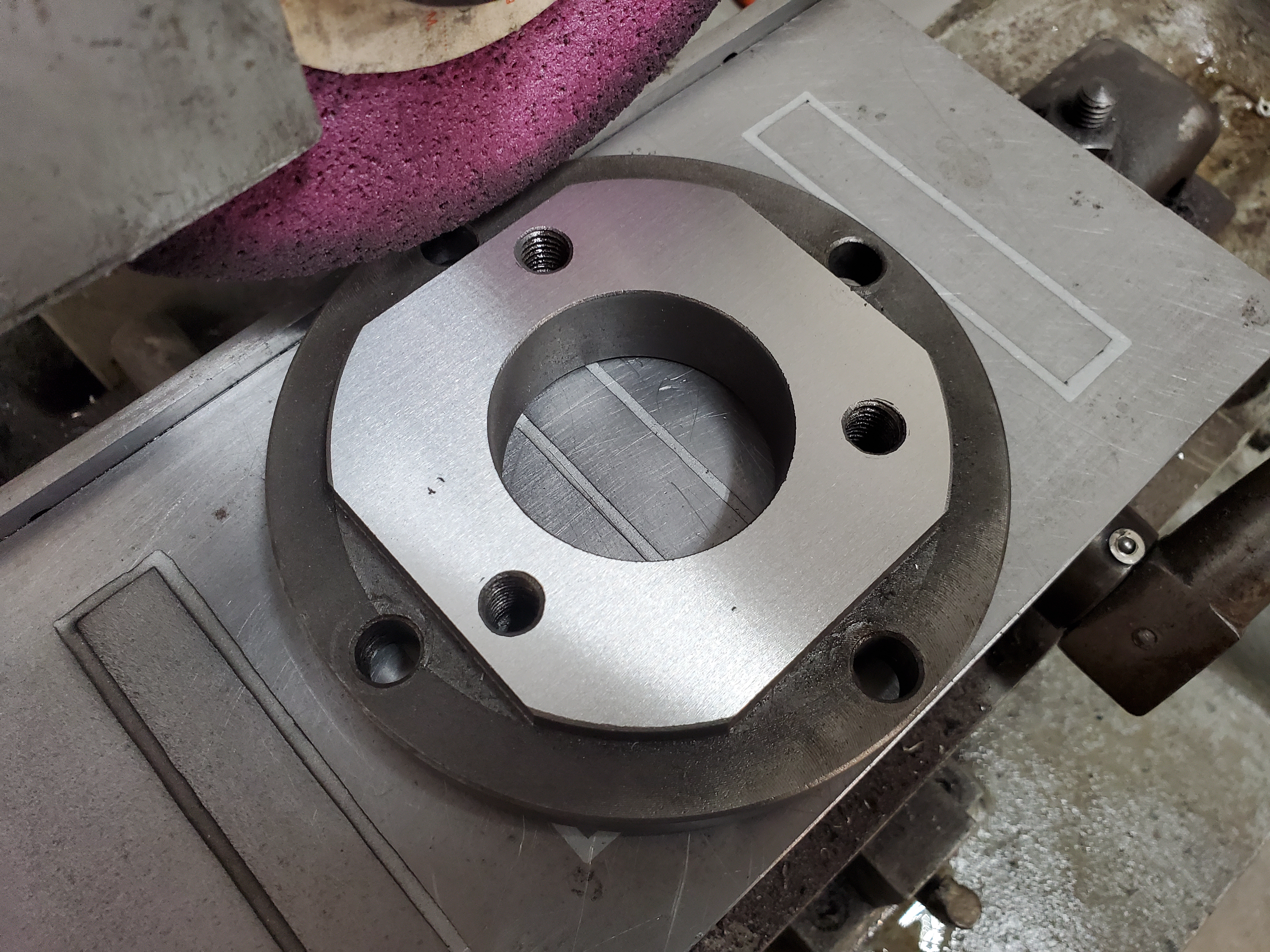

This is the heavy touch off. Probably around 0.0005". Pretty crazy how poor the contact surface is.

This is after another 0.001".

Thus is my 0.0005" clean up.

After this I lightly lapped it and the contact was dead flat.

Once the adapter plate was flat on the back I mounted it on the spindle and turned the face the chuck rides against and then trued the locating diameter. This means that the location is not longer done by the horribly running out step, but by dialing in a gauge pin held in the chuck, and tightening the bolts holding the chuck to the adapter plate.

In my 3 jaw chuck, on a 3/4" pin I can get it to repeat within 0.001" after removing the chuck. This was done several times taking the pin out and taking the chuck off and remounting it. I dialed it in on that pin so it seems to be happy there. It was pretty good at 1.5" but it was a couple months ago. I think it was 0.0015 off at 1.5". A 1/2" gauge pin it will repeat at exactly 0.002". The joys of scroll chucks!

I had to clean up the shoulder on the 4 jaw too so I dialed it in on the body within 0.0005". It repeated right at 0.001" run-out taking it off and back on. I need to check the face for run-out but I haven't yet.

These adapter plates are easy to fix but it is still frustrating that they are so poorly done from the factory.

The adapter plates on the 3 and 4 jaw chucks are not flat. Mine were 0.002" to 0.004" out of flat.

These pictures show the bright areas where I lapped both sides to see where it was touching.

Spindle side.

Side toward the chuck.

I suggest you consider surface grinding and lapping it in, or just lapping the mating surface of the adapter that sits against the spindle nose.

On the lathe I turned the flat face surrounding the spindle nose because it was 0.004" off perpendicular to the spindle nose, which had no run-out. The flat part was dished in the center so it showed little run-out but it wasn't flat. I didn't show this here as I fixed it a few months ago.

This is the heavy touch off. Probably around 0.0005". Pretty crazy how poor the contact surface is.

This is after another 0.001".

Thus is my 0.0005" clean up.

After this I lightly lapped it and the contact was dead flat.

Once the adapter plate was flat on the back I mounted it on the spindle and turned the face the chuck rides against and then trued the locating diameter. This means that the location is not longer done by the horribly running out step, but by dialing in a gauge pin held in the chuck, and tightening the bolts holding the chuck to the adapter plate.

In my 3 jaw chuck, on a 3/4" pin I can get it to repeat within 0.001" after removing the chuck. This was done several times taking the pin out and taking the chuck off and remounting it. I dialed it in on that pin so it seems to be happy there. It was pretty good at 1.5" but it was a couple months ago. I think it was 0.0015 off at 1.5". A 1/2" gauge pin it will repeat at exactly 0.002". The joys of scroll chucks!

I had to clean up the shoulder on the 4 jaw too so I dialed it in on the body within 0.0005". It repeated right at 0.001" run-out taking it off and back on. I need to check the face for run-out but I haven't yet.

These adapter plates are easy to fix but it is still frustrating that they are so poorly done from the factory.