Hi all

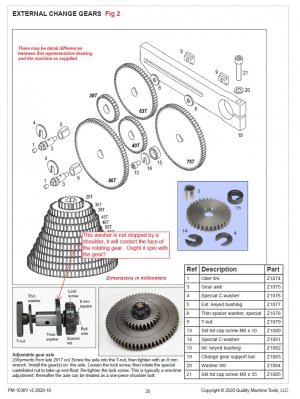

I'm noticing a decent amount of noise from the change gears. There seem to be two issues - one is backlash which I don't see an easy fix for. The other is the somewhat odd means of taking up thrust / end play. To the best of my interpretation there is a thick plain washer bearing on a non machined surface of the gear. The only realistic option I see here is to leave the assembly loose resulting in a decent amount of end play. Since the plain washer does not appear to be an oillite or other bearing material it predictably makes noise when snugged against the gear. I was going to modify this with a ball bearing and wave washers. Anyone else encounter this?

Thanks

I'm noticing a decent amount of noise from the change gears. There seem to be two issues - one is backlash which I don't see an easy fix for. The other is the somewhat odd means of taking up thrust / end play. To the best of my interpretation there is a thick plain washer bearing on a non machined surface of the gear. The only realistic option I see here is to leave the assembly loose resulting in a decent amount of end play. Since the plain washer does not appear to be an oillite or other bearing material it predictably makes noise when snugged against the gear. I was going to modify this with a ball bearing and wave washers. Anyone else encounter this?

Thanks

. My lathe needs quite a bit of backlash to run quietly. The gears will also need to wear in a little bit.

. My lathe needs quite a bit of backlash to run quietly. The gears will also need to wear in a little bit.