- Joined

- Oct 7, 2020

- Messages

- 2,335

Nothing fancy but here is my DRO install. The X access went without a hitch, the Y access I had to redue it and it should really be modified one more time. The Z access has really been a pain but I am getting close.

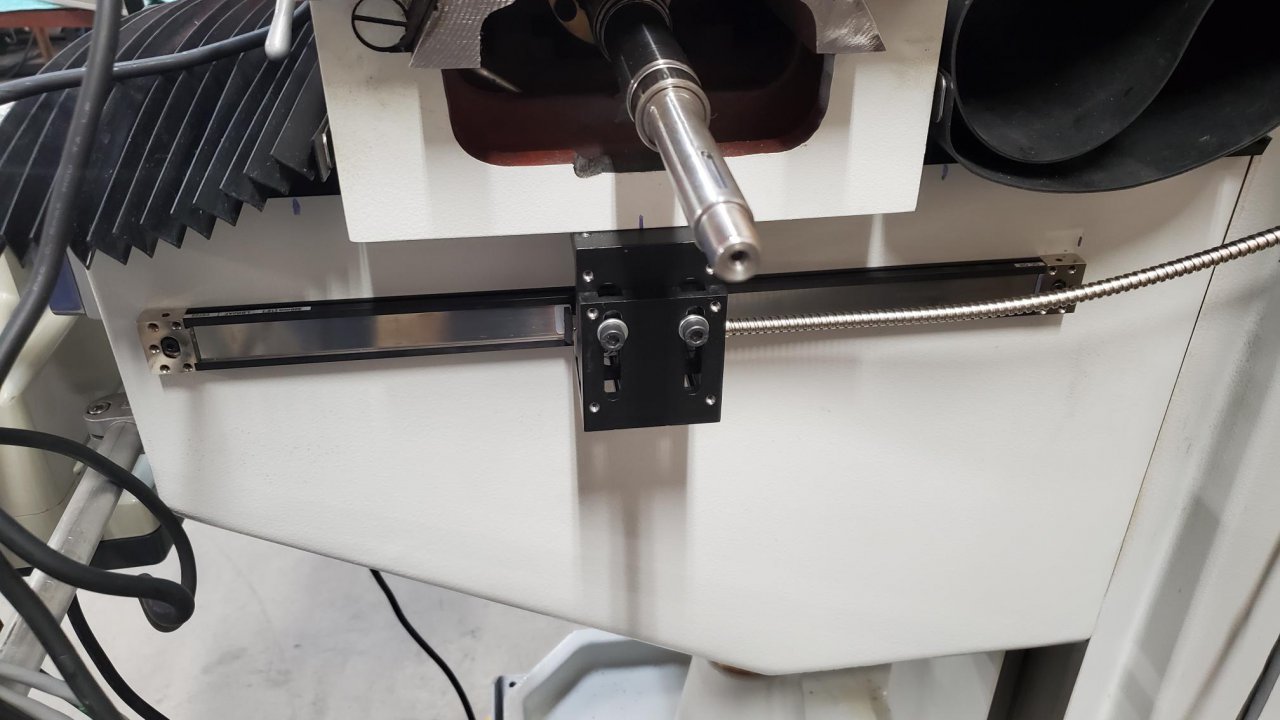

Setting up the X access.

I machined a little notch in the chip cover, much nicer than using a grinder. LOL

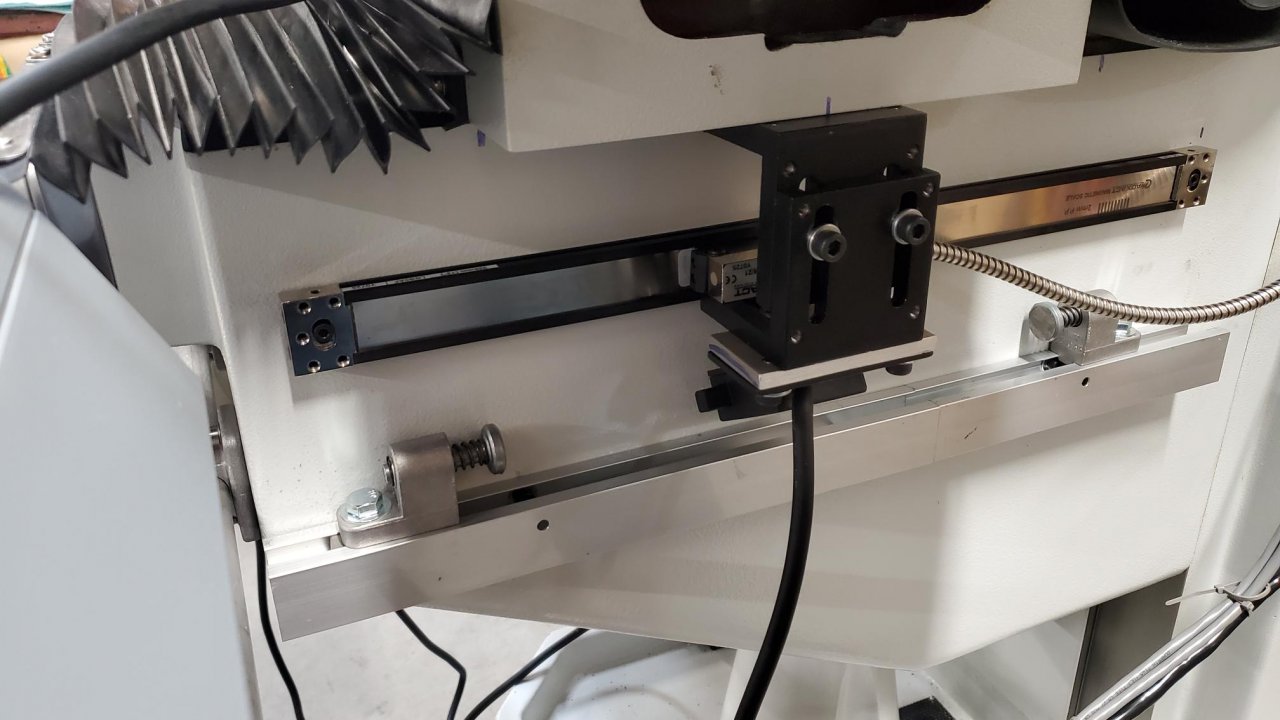

The Y access:

I had removed the X access power feed to gain access to the side of the machine. I had everything for the DRO mounted I was just getting started on the power feed stop when it dawned on me that all the mounting brackets are probably going to interfere with the power feed. Sure enough I was loosing probably 2" or more of travel. These photos are after I rearranged the brackets, loosing maybe 1.25" of travel. It could still be improved but I'm leaving it as is until it becomes a problem.

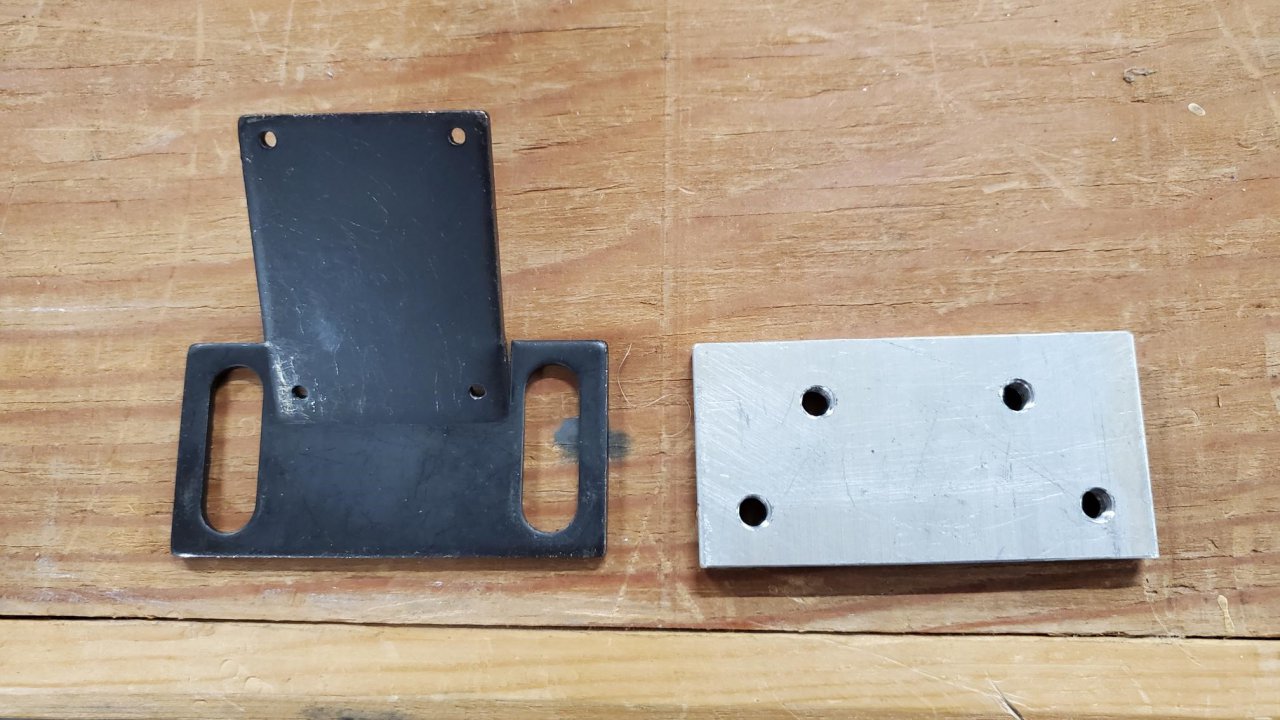

I made this little bracket to mount the Y access power feed stop switch to.

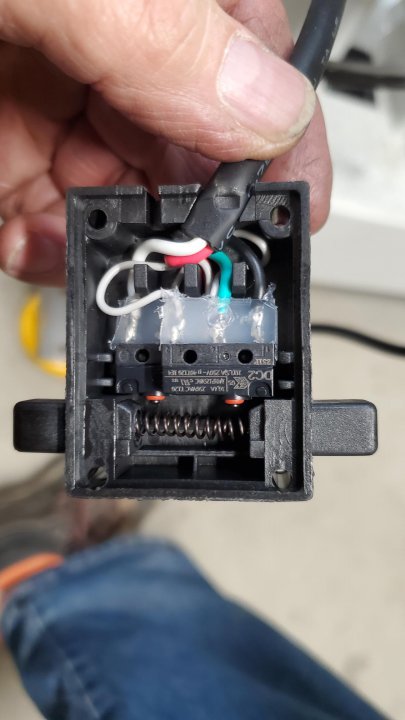

And since I flipped the switch over I had to reverse the internal switches.

Here is how close the power feed comes to the DRO bracket, the power feed stops a little before that, this is hand cranked until full stop.

The Z access:

At this point I am still trying to get the scales to run true to the machine. I have maybe 3 hours into this and still not quite where I would like it. I did machine a couple of spacers for the install. One for the bottom of the scale and one for the read head that if all goes as planned I should be installing tomorrow.

I know it's not much but this is the one of the first times running a mill so that in it's self was pretty cool, and so much nicer the using a grinder to smooth out the spacer. I cut the spacer out of a piece of aluminum angle.

Setting up the X access.

I machined a little notch in the chip cover, much nicer than using a grinder. LOL

The Y access:

I had removed the X access power feed to gain access to the side of the machine. I had everything for the DRO mounted I was just getting started on the power feed stop when it dawned on me that all the mounting brackets are probably going to interfere with the power feed. Sure enough I was loosing probably 2" or more of travel. These photos are after I rearranged the brackets, loosing maybe 1.25" of travel. It could still be improved but I'm leaving it as is until it becomes a problem.

I made this little bracket to mount the Y access power feed stop switch to.

And since I flipped the switch over I had to reverse the internal switches.

Here is how close the power feed comes to the DRO bracket, the power feed stops a little before that, this is hand cranked until full stop.

The Z access:

At this point I am still trying to get the scales to run true to the machine. I have maybe 3 hours into this and still not quite where I would like it. I did machine a couple of spacers for the install. One for the bottom of the scale and one for the read head that if all goes as planned I should be installing tomorrow.

I know it's not much but this is the one of the first times running a mill so that in it's self was pretty cool, and so much nicer the using a grinder to smooth out the spacer. I cut the spacer out of a piece of aluminum angle.