- Joined

- Jan 7, 2016

- Messages

- 3,379

When I purchased this mill my intention was a conversion to CNC. However, I just don't see that happening soon, so in the interim I have decided to install a DRO. It is the typical Chinese DRO which I purchased from Siton Technologies on AliExpress. They sent the 3 scales but the head they sent was only a 2 axis. Looks like they are going to send me the correct one this week. More info in This Thread.

I got some of my ideas from Rimspoke on this forum and plan on mounting the scales in the same positions that he did. Anyhow, just a thread on how I did this in case anyone else has an 833T and is looking for ideas. I am not a great machinist, nor really anything, but I hope someone finds this informative.

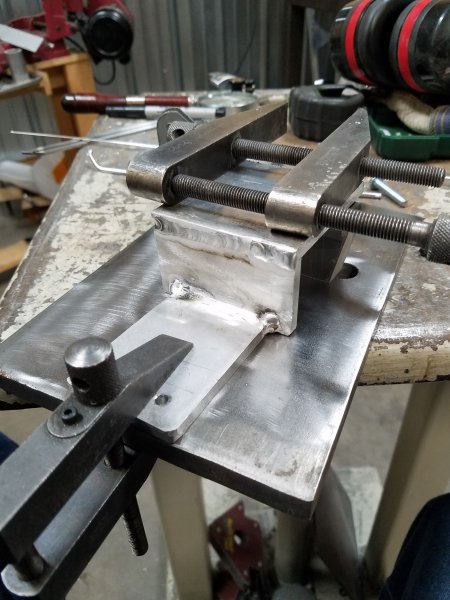

I have a lot of aluminum sitting around, including K100-S tooling plate. First order of business was to made a "wedge" standoff for the Y-axis scale to mount to on the mill base and make it perpendicular to everything else on the mill. For those interesed, the sides of the mill base have a 4 degree slope to them. The scale was attached with a 1/4-28 bolt, but it will be changed to a hex head bolt as soon as I order some.

![20190122_190451[1].jpg 20190122_190451[1].jpg](https://www.hobby-machinist.com/attachments/20190122_190451-1-jpg.285546/)

Next order of business was to determine length and configuration of aluminum bracket that will attach to scale reader. The first "L" was added, keeping it about 1/8" off of the mill base. Hopefully that will still be enough room for the chip shield, although, with the reader and scale upside down, I'm not too worried about contamination.

It actually stayed square after TIG'ing it.

Next order of business was to add the next vertical piece that drops down to the head reader. Had some tooling plate that I cut, which of course was .020" too short, so a couple shims helped me out.

I added a .25" thick spacer at the bottom of the bracket to attach the reader to. Apparently I forgot to take a picture after I welded it on but here it is after a quick sand blast treatment. I don't really like how that turned out so I might re-do that, cosmetic reasons only.

Ready to get mounted to the mill....

Mounted up on the "Y" axis.

More to follow in the coming days..... ( I hope)

I got some of my ideas from Rimspoke on this forum and plan on mounting the scales in the same positions that he did. Anyhow, just a thread on how I did this in case anyone else has an 833T and is looking for ideas. I am not a great machinist, nor really anything, but I hope someone finds this informative.

I have a lot of aluminum sitting around, including K100-S tooling plate. First order of business was to made a "wedge" standoff for the Y-axis scale to mount to on the mill base and make it perpendicular to everything else on the mill. For those interesed, the sides of the mill base have a 4 degree slope to them. The scale was attached with a 1/4-28 bolt, but it will be changed to a hex head bolt as soon as I order some.

Next order of business was to determine length and configuration of aluminum bracket that will attach to scale reader. The first "L" was added, keeping it about 1/8" off of the mill base. Hopefully that will still be enough room for the chip shield, although, with the reader and scale upside down, I'm not too worried about contamination.

It actually stayed square after TIG'ing it.

Next order of business was to add the next vertical piece that drops down to the head reader. Had some tooling plate that I cut, which of course was .020" too short, so a couple shims helped me out.

I added a .25" thick spacer at the bottom of the bracket to attach the reader to. Apparently I forgot to take a picture after I welded it on but here it is after a quick sand blast treatment. I don't really like how that turned out so I might re-do that, cosmetic reasons only.

Ready to get mounted to the mill....

Mounted up on the "Y" axis.

More to follow in the coming days..... ( I hope)