I'm in search of a few opinions and advice in my quest for the right sized bench top mill. Specifically related to the PM-728VT, at the top of my list. I say "right sized" because I know bigger and heavier is better but the plan is to do 95% milling in aluminum. No specific part/task, just to learn and have as another tool in my shop.

In general...

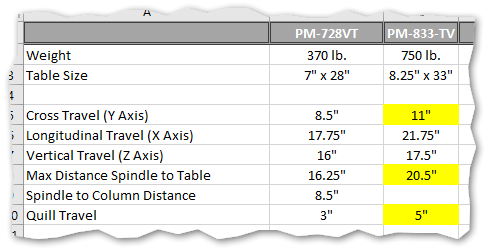

The quill travel and max Distance spindle maybe important upgrades I may wish I had. Aside that, seems like the working envelope is similar.

In general...

- What's a practical (approximate) capacity for the largest x/y/z part you could cut out, face mill, etc...?

- Can the spindle w/end mill reach the entire surface of the 7" x 28" bed?

- Can the spindle w/end mill reach the entire surface of the 7" x 28" bed?

- Is the 16.25" Max Distance spindle a concern since you lose fair amount with drill chuck, mounted vise, drill bits/end mills extended?

- Can a fixture plate compensate (help minimize the bulk of a traditional vise) and also aid in "just as good" clamping setups compared to a vice?

- I caught a thread discussing the tramming the 728vt of this mill and someone called out the https://saundersmachineworks.com/ fixture plate... they have low profile vice setups... though, in practice they may be more cumbersome than a traditional vice.... you can also mount a vice on top, though another 1" gone from vertical height.

- I assume a 4" vise is the appropriate size for a 7" by 28" bed.

- Aside from trying to drill large holes 1/2" or larger in aluminum, is the 1 HP DC motor a good size for facing and general end milling with 1/4" to 1/2" end mills?

- I know understand variable speed motors typically suffer torque at low speeds. I'm "guestimating" that won't be of concern in aluminum if sticking to smaller drilled holes and end mills.

- Can a 1/4" end mill take a 1/4" DOC in aluminum for a slot?

- Can a 1/4" end mill take off 1/8" of material on 1" thick stock on the end?

- ... just trying to get a sense of what it can do without pushing it to it's limits.

The quill travel and max Distance spindle maybe important upgrades I may wish I had. Aside that, seems like the working envelope is similar.

Last edited: