I purchased a 5C collet chuck from Precision Matthews last month and thought I would write up a quick review for anyone considering it. Overall it is a nice chuck, the set thru feature is nice to have, but mine needed some work to operate smoothly. I don't know if this is indicative of these chucks, or if I had a Monday morning production unit. This chuck is the one with a D1-4 mounting plate.

When I first installed it, I was having difficulty getting the runout lower than 0.001". I removed the mounting plate to inspect it and noticed the counterbores for the pin screws had very little clearance and the edges were sharp. I placed it on my surface place and it was not parallel due to some raised edges, a light sanding on the surface plate removed that and the mounting plate was now much better.

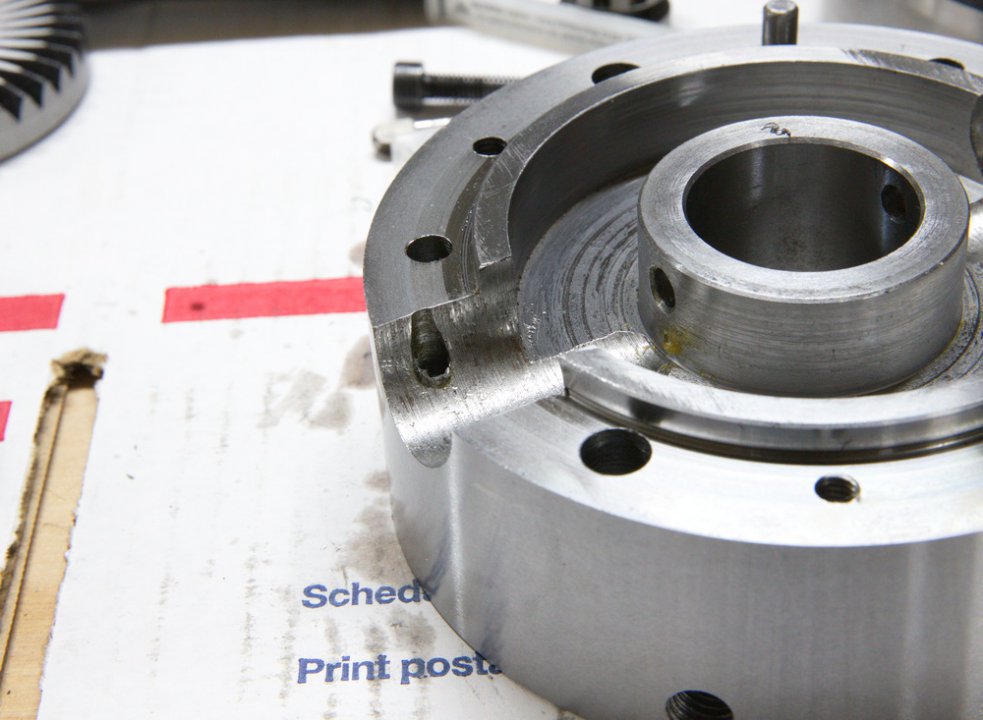

When turning the pinion gear, there was a lot of roughness, so I disassembled the chuck and was surprised at the poor quality machining on the back surface and the holes for the pinion. The back surface does not matter to the operation of the chuck, but it looks like a broken insert was used. The front surface and bore for the scroll plate was ground to a nice finish, and everything fit well there. I found a burr from the locating pin for one of the pinions that was rubbing against the gear teeth and causing the roughness I experienced.

While disassembling the chuck, I noticed the location of one of the push off holes was located at a pinion gear. To separate the chuck halves without cocking it, you need all three. It seems strange to place it there, but I guess they could not fit it elsewhere. Next time I open this up I will try removing the pinion gears first and then use a rod of the right diameter in the holes to push off against. The threads for the push off holes were poor quality and damaged the M6 screws while separating the chuck body halves. I retapped them and the replacement screws go in there much better.

The collets from PM work well in this chuck, I bought a metric set, but needed a 3/8" collet and decided to try a Lyndex collet. The Lyndex collet is a higher quality than the Chinese made collets as you would expect, but I have trouble inserting this collet into the chuck. The clearance between this collet the collet chuck bore is so close that it needs to go exactly straight, or it won't make it to the threads to get drawn in. A bit of oil helps, but I'm thinking the internal bore on the chuck might be slightly undersize, or I possibly got a collet that is slightly too big. I don't know the tolerances on either, so for now not making any changes.

As you can see in the next picture, there is grease for the gears, but it was not spread very well on the teeth, so doesn't look like it was doing anything. I used this chuck a little bit before opening it up, so running at 1800 rpm did not sling the grease to the outer diameter where it could be of use. I removed the gear and added some new grease spread on the teeth.

After cleaning it up, the operation is much better. I was going to clean up the surface of the pinion bores, but since there was already a lot of clearance between the pinion and bore, I only did a light polish to remove any high spots. Overall for the price I think it is a good value considering you need to spend at least twice as much to get a Bison. Whether it is worth twice as much as the Chinese brands you can get on Ebay that likely need work to get in proper condition is something I can't answer since I don't have one of those. I just watched Clough42's video on his cheap Chinese collet chuck he released today as I was writing this and this one looks a lot better than his. Knowing what I know now, I probably would have sprung for a Bison, but this will likely give me many years of good service until it needs to get replaced.

When I first installed it, I was having difficulty getting the runout lower than 0.001". I removed the mounting plate to inspect it and noticed the counterbores for the pin screws had very little clearance and the edges were sharp. I placed it on my surface place and it was not parallel due to some raised edges, a light sanding on the surface plate removed that and the mounting plate was now much better.

When turning the pinion gear, there was a lot of roughness, so I disassembled the chuck and was surprised at the poor quality machining on the back surface and the holes for the pinion. The back surface does not matter to the operation of the chuck, but it looks like a broken insert was used. The front surface and bore for the scroll plate was ground to a nice finish, and everything fit well there. I found a burr from the locating pin for one of the pinions that was rubbing against the gear teeth and causing the roughness I experienced.

While disassembling the chuck, I noticed the location of one of the push off holes was located at a pinion gear. To separate the chuck halves without cocking it, you need all three. It seems strange to place it there, but I guess they could not fit it elsewhere. Next time I open this up I will try removing the pinion gears first and then use a rod of the right diameter in the holes to push off against. The threads for the push off holes were poor quality and damaged the M6 screws while separating the chuck body halves. I retapped them and the replacement screws go in there much better.

The collets from PM work well in this chuck, I bought a metric set, but needed a 3/8" collet and decided to try a Lyndex collet. The Lyndex collet is a higher quality than the Chinese made collets as you would expect, but I have trouble inserting this collet into the chuck. The clearance between this collet the collet chuck bore is so close that it needs to go exactly straight, or it won't make it to the threads to get drawn in. A bit of oil helps, but I'm thinking the internal bore on the chuck might be slightly undersize, or I possibly got a collet that is slightly too big. I don't know the tolerances on either, so for now not making any changes.

As you can see in the next picture, there is grease for the gears, but it was not spread very well on the teeth, so doesn't look like it was doing anything. I used this chuck a little bit before opening it up, so running at 1800 rpm did not sling the grease to the outer diameter where it could be of use. I removed the gear and added some new grease spread on the teeth.

After cleaning it up, the operation is much better. I was going to clean up the surface of the pinion bores, but since there was already a lot of clearance between the pinion and bore, I only did a light polish to remove any high spots. Overall for the price I think it is a good value considering you need to spend at least twice as much to get a Bison. Whether it is worth twice as much as the Chinese brands you can get on Ebay that likely need work to get in proper condition is something I can't answer since I don't have one of those. I just watched Clough42's video on his cheap Chinese collet chuck he released today as I was writing this and this one looks a lot better than his. Knowing what I know now, I probably would have sprung for a Bison, but this will likely give me many years of good service until it needs to get replaced.