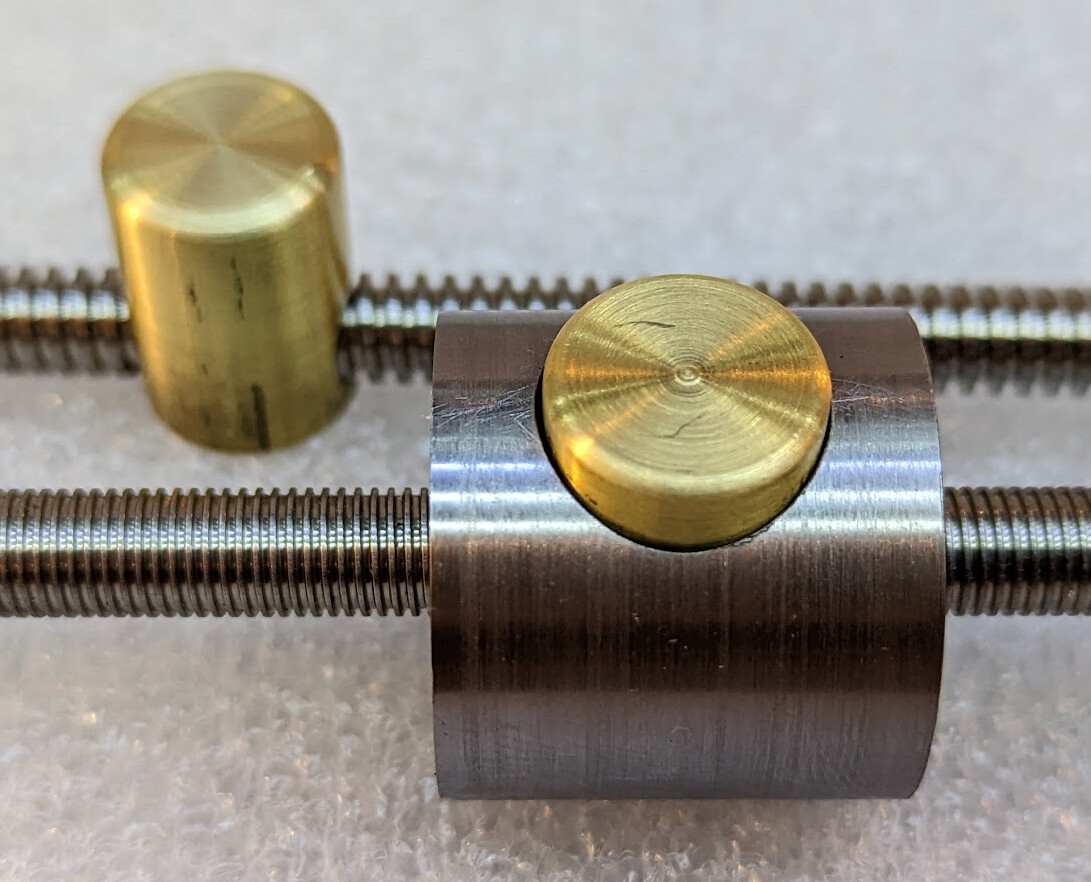

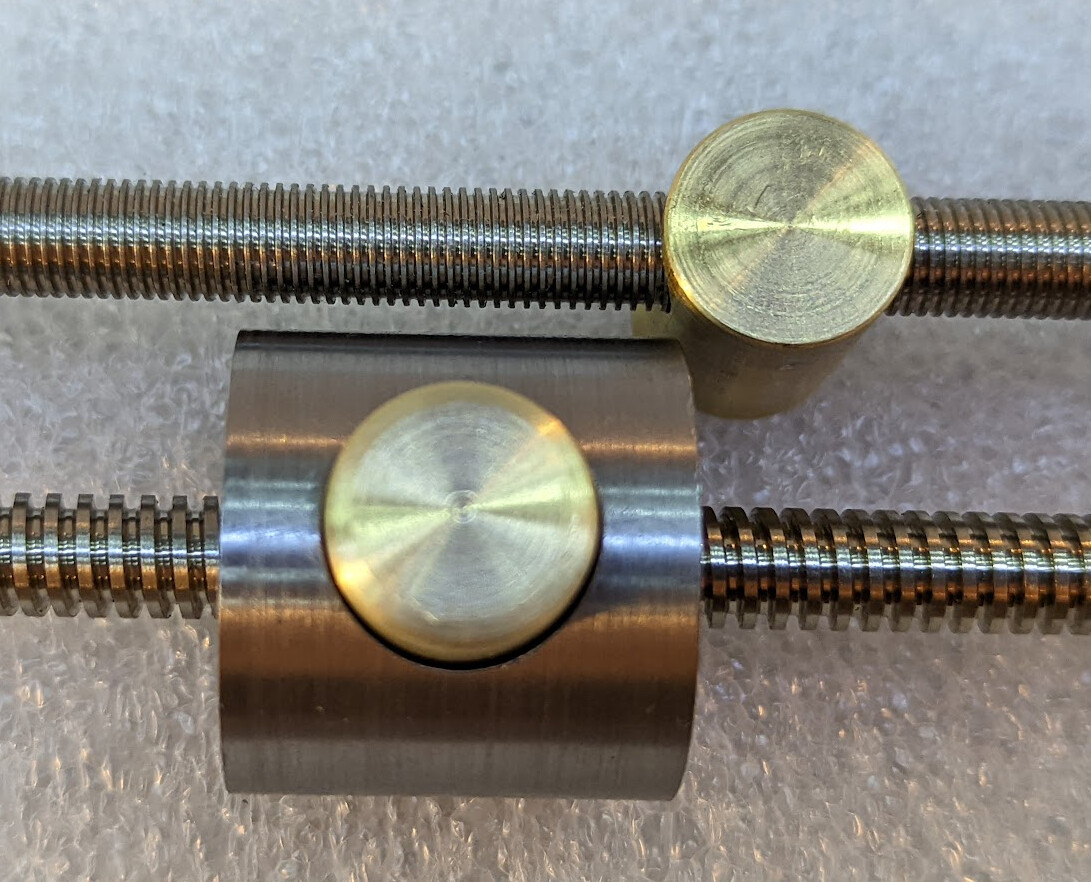

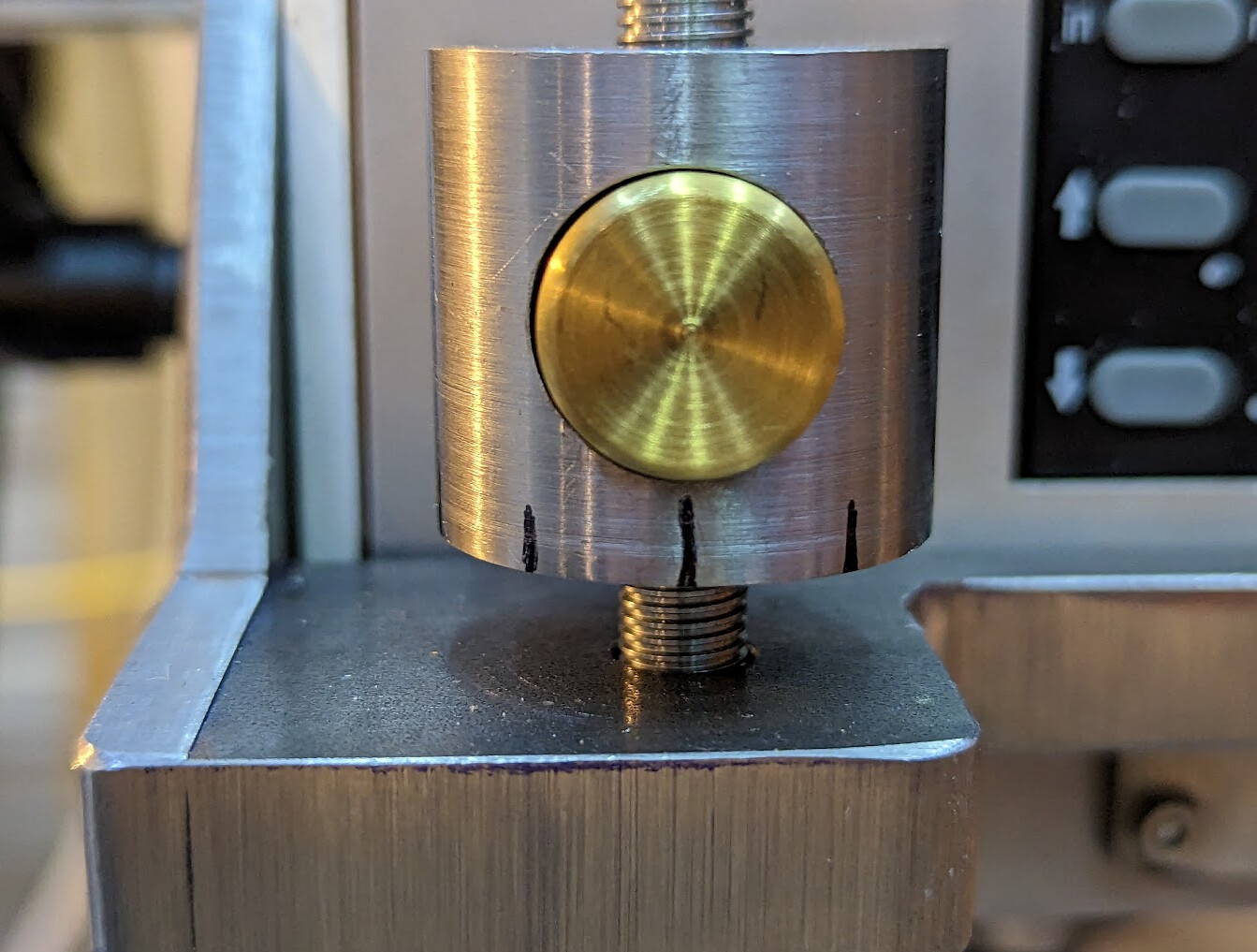

I got tired of not having a depth stop on my PM-30MV. I learned somewhere on the forum here that a graduated nut is called an "educated nut" and designed my own that would work with 8mm lead screw — and made buttons for both 2mm pitch/lead and 1mm pitch/lead screws that fit into the same nut body.

If I had it to do over again, I'd only make the 1mm pitch/lead screws, which is close to the typical 20tpi imperial graduated nuts; that's 1.27mm pitch. It was tricky to source the 1mm pitch/lead screws; I had to buy both the screws and the tap on aliexpress because I couldn't find them anywhere in the US. I do almost everything in metric, so metric was more convenient for me than imperial.

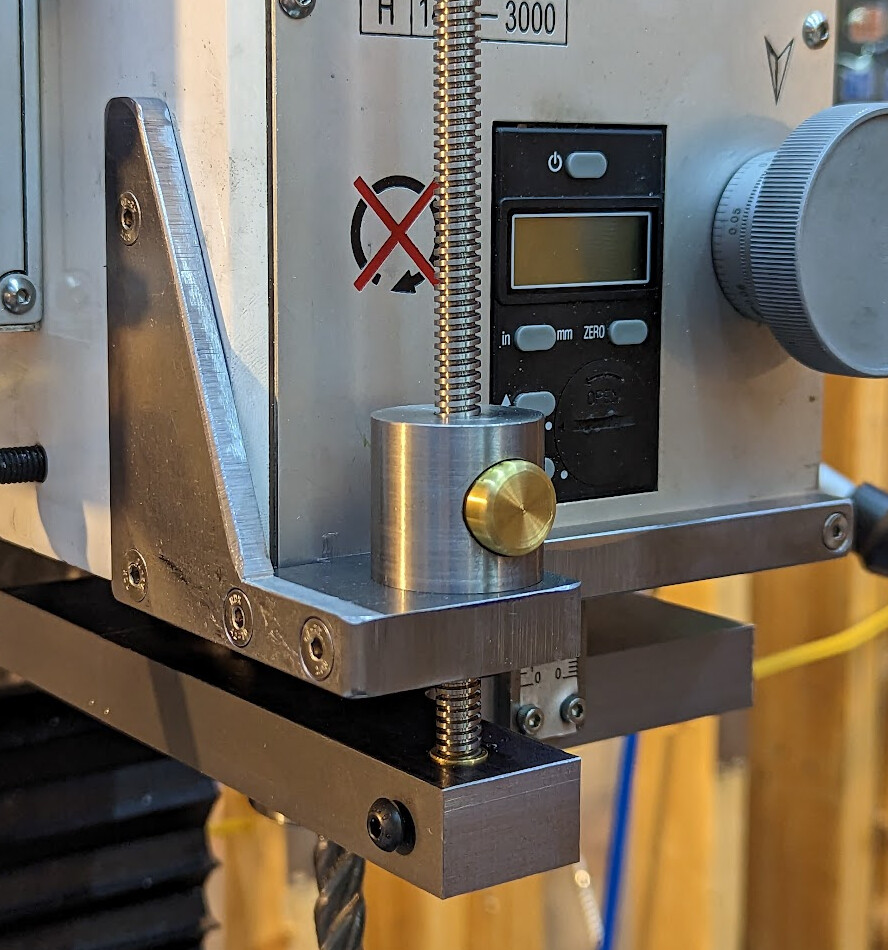

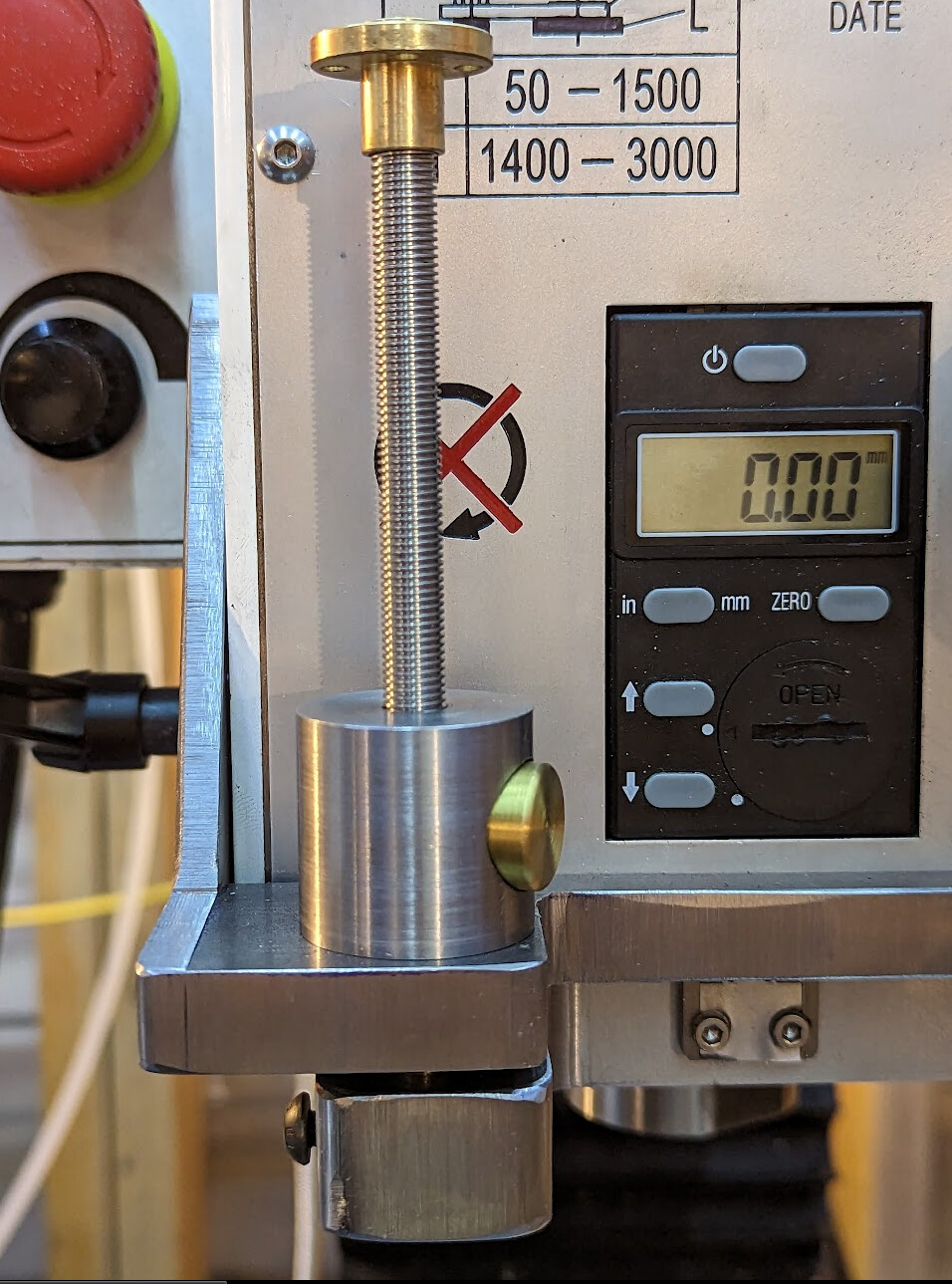

Then I made a rectangular quill collar out of 3/4" CRS to replace the original. My new collar has a tab sticking out of it to hold the lead screw. I made a stop plate (from 1/2" CRS) and bracket (from 1/4" CRS) which screw into the mill head in place of an existing M4 face plate screw and the worse-than-useless chip guard that I assume everyone removes along with the rest of the packing material that the mill ships with.

So far I've done 10 gradations (.1mm for the lead screw I expect to always use in practice, now that I've tried both) in sharpie so that I can see whether that's enough in practice, before I engrave any lines.

I wrote this up in much longer form, including false starts, on Maker Forums. I would suggest that anyone doing a similar project start by using this as inspiration and not a concrete design, but if you'd like to be amused you are welcome to see the long form build log that's written for an audience that mostly doesn't do machining and which I hoped to be amusing to a more general maker audience there...

If I had it to do over again, I'd only make the 1mm pitch/lead screws, which is close to the typical 20tpi imperial graduated nuts; that's 1.27mm pitch. It was tricky to source the 1mm pitch/lead screws; I had to buy both the screws and the tap on aliexpress because I couldn't find them anywhere in the US. I do almost everything in metric, so metric was more convenient for me than imperial.

Then I made a rectangular quill collar out of 3/4" CRS to replace the original. My new collar has a tab sticking out of it to hold the lead screw. I made a stop plate (from 1/2" CRS) and bracket (from 1/4" CRS) which screw into the mill head in place of an existing M4 face plate screw and the worse-than-useless chip guard that I assume everyone removes along with the rest of the packing material that the mill ships with.

So far I've done 10 gradations (.1mm for the lead screw I expect to always use in practice, now that I've tried both) in sharpie so that I can see whether that's enough in practice, before I engrave any lines.

I wrote this up in much longer form, including false starts, on Maker Forums. I would suggest that anyone doing a similar project start by using this as inspiration and not a concrete design, but if you'd like to be amused you are welcome to see the long form build log that's written for an audience that mostly doesn't do machining and which I hoped to be amusing to a more general maker audience there...