- Joined

- Apr 26, 2015

- Messages

- 135

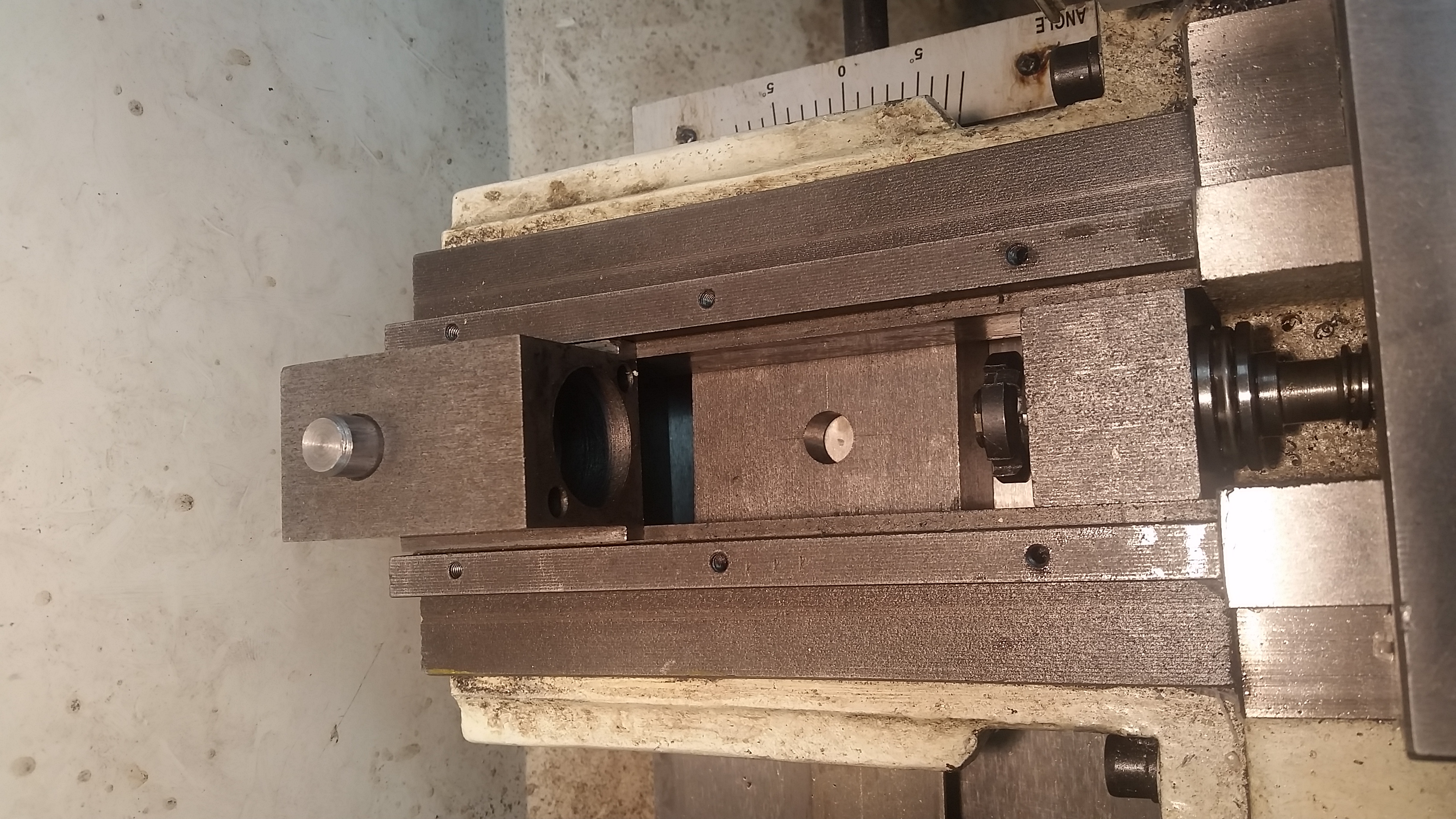

I have a 2006, PM 1440 that has developed a fair amount of play in the pin that anchors the cross feed screw to the taper attachment dovetail block. The wear is mostly in the cast iron socket with a minor amount on the dowel pin. The pin is still tight in the upper block that bolts to the thrust bearing block.

I think what I am going to try is boring out the pin hole in the dovetail block and press in a hardened steel bushing with loctite 609. Hopefully that will provide a better wear point than the soft cast iron and if I have a problem again I can just replace the dowel pin and bushing. Has anyone else solved this problem with their taper attachments? I would be interested in hearing how it was done. The other problem I would like to solve is the nut that adjusts the preload on the thrust bearings won't stay tight. In the second picture I think you can just see the nut and locking washer that was used. The problem is the bottom tab of the locking washer doesn't fit the keeway tight and allows the nut to back off losing the preload on the bearings. I have had two different thoughts on how to correct this. The fast and easy way would be to just remove the washer and install another nut and just jam them together. The downside to this, that I can see, would be that getting the preload right would be harder. The other thought I have had is to make a split nut with a clamp bolt to lock down after the preload is adjusted. Any thoughts on this one? Thanks.

Hello, my name is Brian and I'm a toolaholic!

I think what I am going to try is boring out the pin hole in the dovetail block and press in a hardened steel bushing with loctite 609. Hopefully that will provide a better wear point than the soft cast iron and if I have a problem again I can just replace the dowel pin and bushing. Has anyone else solved this problem with their taper attachments? I would be interested in hearing how it was done. The other problem I would like to solve is the nut that adjusts the preload on the thrust bearings won't stay tight. In the second picture I think you can just see the nut and locking washer that was used. The problem is the bottom tab of the locking washer doesn't fit the keeway tight and allows the nut to back off losing the preload on the bearings. I have had two different thoughts on how to correct this. The fast and easy way would be to just remove the washer and install another nut and just jam them together. The downside to this, that I can see, would be that getting the preload right would be harder. The other thought I have had is to make a split nut with a clamp bolt to lock down after the preload is adjusted. Any thoughts on this one? Thanks.

Hello, my name is Brian and I'm a toolaholic!