- Joined

- Jun 12, 2014

- Messages

- 5,061

My previous designs for VFD control systems have been posted, and I have been building pretty much the same design for about a year. I have made iterative design changes based on the requests of other hobbyists, so each system is tweaked a bit for each individual's preferences. The latest changes included a 3 way coolant selector so one can either choose continuous or intermittent (only with spindle rotation) coolant, variations on using a coolant relay/contactor/voltage source, different braking pattern selections, use of plug and socket connects for the front control panel and proximity sensor cable, Jog Joystick, and a few other changes. The only lathe control box terminal connections are for the spindle cable and 12/24VDC power for tach, lights, etc.

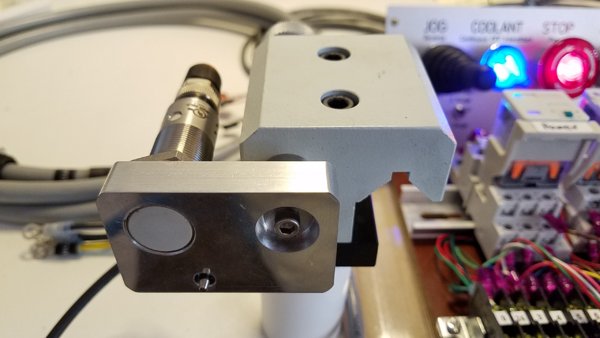

The proximity stop system which use to be bolted onto the micrometer stop is now integrated into the micrometer stop. This makes it more compact, yet the mechanism can be removed by loosening an Allan screw. This simplifies the mechanism, but requires me to machine the micrometer stop to install the mechanism. The proximity stop uses an induction sensor which has been reliable and quite accurate, but there is an additional mechanical limit switch as a back-up. The proximity sensor cable requires modifications to incorporate this limit switch and both are integrated into the lathe control system.

I have been mostly recommending using the Hitachi WJ200 VFD for use with the control systems I have designed, although the new system design can be adapted to some other VFDs with a few modifications. The WJ200 VFD has proven to be reliable and works well, but I have been considering use of Yaskawa or ABB VFDs at some point in the future. VFD programming seems to be the biggest hurdle for most individuals, and different VFDs have their quirks. Since most of my control systems use 5-7 VFD inputs to control different functions, and require more programming controls, many basic VFDs do not have these features and cannot be used.

The latest PM 1340GT lathes have undergone some changes in their design/wiring, which has prompted me to make further revisions in my control system designs to make it inclusive of the PM 1340GT changes and also more universal/adaptable to other lathes. These include the ability to wire in safety interlocks for the belt cover, and in some models a chuck shield interlock. Other lathes with manual foot brakes can also be use the new control system, but require a different brake switch and the use of an addition VFD input to issue the freewheel command. Factory lathes with VFDs that have foot brakes often do not have a mechanical foot brake, it just acts as an E-Stop and the VFD brakes the lathe. But after having done a few lathe system installs my recommendation if your lathe does have a mechanical foot brake, I would suggest keeping it intact and have the VFD braking disabled when the mechanical foot brake is engaged.

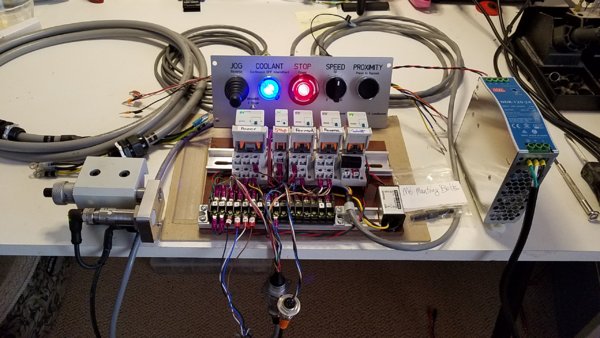

So I have reworked my system design (I call it the Next-Step Control System) to add an extra stop relay (adds an additional safety layer), which overrides the forward/reverse relays commands when the spindle switch is in the stop position. This is in addition to the power relay which controls both low voltage power and VFD input connections, and lockouts the VFD run commands at power up. There are a number of other interlock safety systems incorporated into the design. The lathe control box is now too crowded for the power supply, it is now moved to the VFD cabinet which allows the use of a coolant contactor +/- overload relay if one is using a 240VAC coolant pump. This also allows for a full sized DIN rail power supply which is easier to source. Wiring connections have been simplified to reduce the terminals used for the internal control system connections, a 5A schottky diode has been added at the input power terminals to prevent relay voltage spikes and also prevent damage to the control system should the power supply polarity be connected incorrectly. There have been a few other changes, the switch gear has mostly remained the same. I have thought of going to a single PID controller instead of individual relays, this could be programmed for other features, but the relay control systems are reliable and relatively simple. PID controllers have much greater depth of sensor inputs and programming features, so one thought I might look into is using it to drive a cross slide stepper motor to cut tapers. I am actually a bit surprised is that manufactures have not chucked the lathe gearboxes and replaced them with an encoder feedback drive for the lead screw/power feed. Probably cost less and have more flexibility, but not sure on the long term reliability (some Hardinge HLV-H lathes have this feature). Probably easier to just do a full CNC conversion.

http://www.autoartisans.com/ELS/

http://www.babinmachine.com/index.php?HLVELECLEAD

With my last control system build I was asked to design a new 5 hole replacement control panel for the PM 1340GT control switches. I used Front Panel Express to fabricate these panels out of 2.5mm clear anodized aluminum. It would be nice to do this in house, but it is not practical for the few control systems I make. If someone is interested in the panel design file I will send it to so they can order the panel directly from Front Panel Express. They do nice work if you need custom panel work. The Next-Step Control System and panel is in the following pictures.

The proximity stop system which use to be bolted onto the micrometer stop is now integrated into the micrometer stop. This makes it more compact, yet the mechanism can be removed by loosening an Allan screw. This simplifies the mechanism, but requires me to machine the micrometer stop to install the mechanism. The proximity stop uses an induction sensor which has been reliable and quite accurate, but there is an additional mechanical limit switch as a back-up. The proximity sensor cable requires modifications to incorporate this limit switch and both are integrated into the lathe control system.

I have been mostly recommending using the Hitachi WJ200 VFD for use with the control systems I have designed, although the new system design can be adapted to some other VFDs with a few modifications. The WJ200 VFD has proven to be reliable and works well, but I have been considering use of Yaskawa or ABB VFDs at some point in the future. VFD programming seems to be the biggest hurdle for most individuals, and different VFDs have their quirks. Since most of my control systems use 5-7 VFD inputs to control different functions, and require more programming controls, many basic VFDs do not have these features and cannot be used.

The latest PM 1340GT lathes have undergone some changes in their design/wiring, which has prompted me to make further revisions in my control system designs to make it inclusive of the PM 1340GT changes and also more universal/adaptable to other lathes. These include the ability to wire in safety interlocks for the belt cover, and in some models a chuck shield interlock. Other lathes with manual foot brakes can also be use the new control system, but require a different brake switch and the use of an addition VFD input to issue the freewheel command. Factory lathes with VFDs that have foot brakes often do not have a mechanical foot brake, it just acts as an E-Stop and the VFD brakes the lathe. But after having done a few lathe system installs my recommendation if your lathe does have a mechanical foot brake, I would suggest keeping it intact and have the VFD braking disabled when the mechanical foot brake is engaged.

So I have reworked my system design (I call it the Next-Step Control System) to add an extra stop relay (adds an additional safety layer), which overrides the forward/reverse relays commands when the spindle switch is in the stop position. This is in addition to the power relay which controls both low voltage power and VFD input connections, and lockouts the VFD run commands at power up. There are a number of other interlock safety systems incorporated into the design. The lathe control box is now too crowded for the power supply, it is now moved to the VFD cabinet which allows the use of a coolant contactor +/- overload relay if one is using a 240VAC coolant pump. This also allows for a full sized DIN rail power supply which is easier to source. Wiring connections have been simplified to reduce the terminals used for the internal control system connections, a 5A schottky diode has been added at the input power terminals to prevent relay voltage spikes and also prevent damage to the control system should the power supply polarity be connected incorrectly. There have been a few other changes, the switch gear has mostly remained the same. I have thought of going to a single PID controller instead of individual relays, this could be programmed for other features, but the relay control systems are reliable and relatively simple. PID controllers have much greater depth of sensor inputs and programming features, so one thought I might look into is using it to drive a cross slide stepper motor to cut tapers. I am actually a bit surprised is that manufactures have not chucked the lathe gearboxes and replaced them with an encoder feedback drive for the lead screw/power feed. Probably cost less and have more flexibility, but not sure on the long term reliability (some Hardinge HLV-H lathes have this feature). Probably easier to just do a full CNC conversion.

http://www.autoartisans.com/ELS/

http://www.babinmachine.com/index.php?HLVELECLEAD

With my last control system build I was asked to design a new 5 hole replacement control panel for the PM 1340GT control switches. I used Front Panel Express to fabricate these panels out of 2.5mm clear anodized aluminum. It would be nice to do this in house, but it is not practical for the few control systems I make. If someone is interested in the panel design file I will send it to so they can order the panel directly from Front Panel Express. They do nice work if you need custom panel work. The Next-Step Control System and panel is in the following pictures.