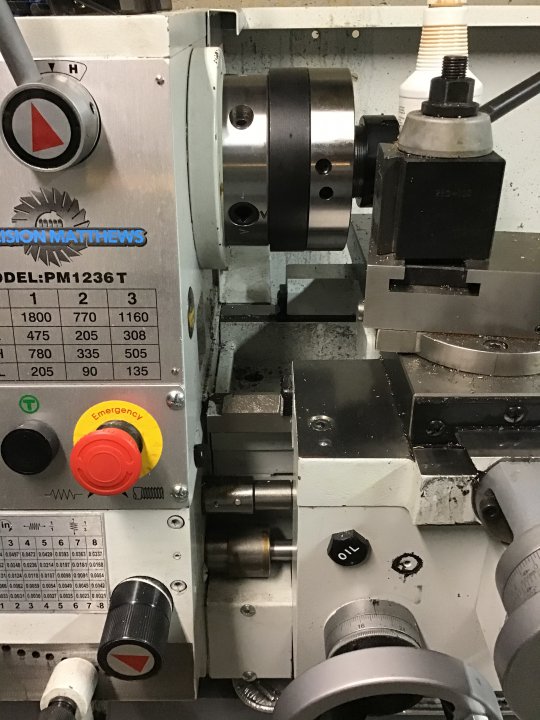

This was initially meant to be a 6 month review, but life got in the way and it is now a one year review. I have had my PM1236T for a year now and thought I would write my experience with it so far for anyone considering this lathe. I already posted about getting it into my basement last year, so the following is after setting it up and using it.

My first impressions were a bit mixed, I bought a Taiwanese lathe expecting it to be better than a Chinese made one, but some of the fits and finish were more Chinese looking. The bed casting was not fully machined like I expected, you can see in this first picture the roughness on the insides of the ways. This doesn’t affect the operation of the lathe, but it does make you take a closer eye to the rest of the machine.

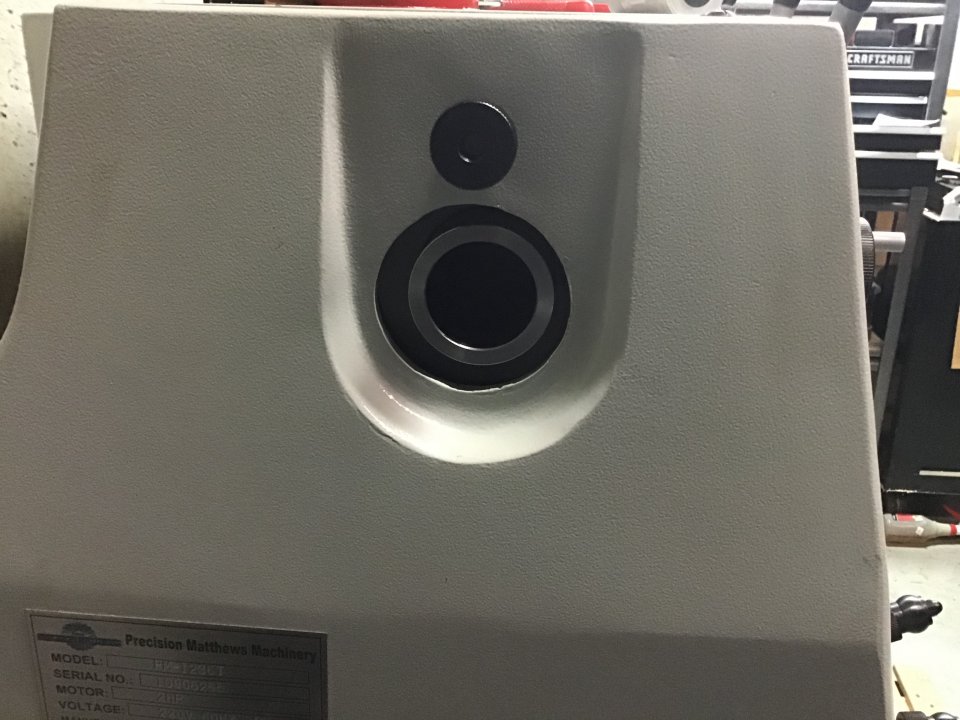

The second problem I discovered was the gear cover was machined off center. You can see in this picture that the hole in the guard is not centered well at all around the spindle. It appears this was not set up properly when having the holes bored since the holes for the mounting studs are not centered in the recesses. There is just enough room to fit a spider without rubbing on the cover, but I will probably open this hole up a bit to give some more room.

This lathe comes with a 3 jaw chuck. I don’t know where the chuck was made since there are not any markings on it, but not impressed with it. The tapered bore for the D1-4 spindle is on the loose side, when loosening the camlocks, the chuck will fall off the spindle if you don’t hold it. My other chucks need a tap with a rubber mallet to break free. I might take a skim cut one of these days to get it to fit better, but since I don’t use it very much, I might just leave it for now. I tested the runout of the jaws using an endmill (the only ground item I had that I could chuck) and also with a cylindrical roller bearing inner ring about 80mm bore. The runout was 0.007” with one set of jaws

and 0.005” with the other set. It was repeatable when rotating the end mill and ring, so the runout is in the jaws and not the items being used. I expected better than that from Taiwan, Shars lists their Chinese chucks should have runout less than 0.003”, so I don’t think it unreasonable to have at least that. The serial number on the two sets of jaws was different, the jaws on my Bison chuck match the

serial number of the cuck body, so I called PM to inquire about them not matching. According to them, the serial number are for the jaws and are not meant to match a particular chuck. That might explain the runout.

Most of what I machine is metric, so I was glad to have a quick change gearbox that cuts so many metric threads with only a few changes in gears. But, I was very surprised one of the most common thread pitches was not included in the chart. M12 course thread is 1.75 and it is not in the thread tables at all, and 0.8 used for M5 was not there either, but I usually use dies for threads that size. I made a table with different gear combinations and found that using 32x40 gear combination gives me both of those threads.

Using the machine is a huge step up from the 9x20 Jet I started out on. Runout on the spindle barely moves my test indicator and the quality of the cut is excellent considering the size of the lathe. I have been using mostly carbide tooling and the lathe handles that very well. I use CCGT and DCGT for the most part and like it a lot.

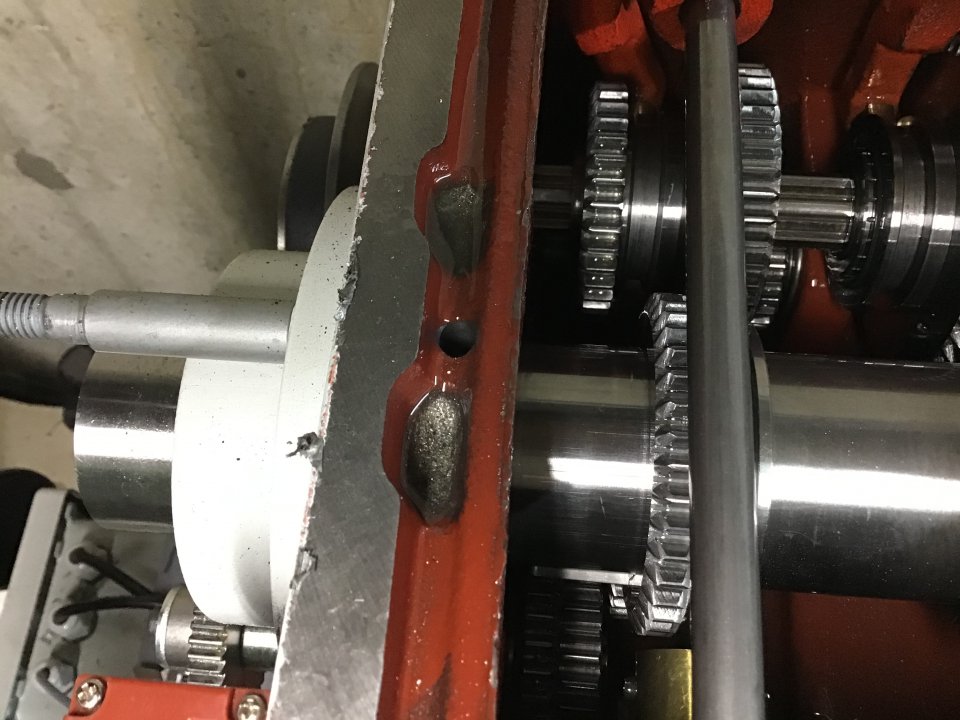

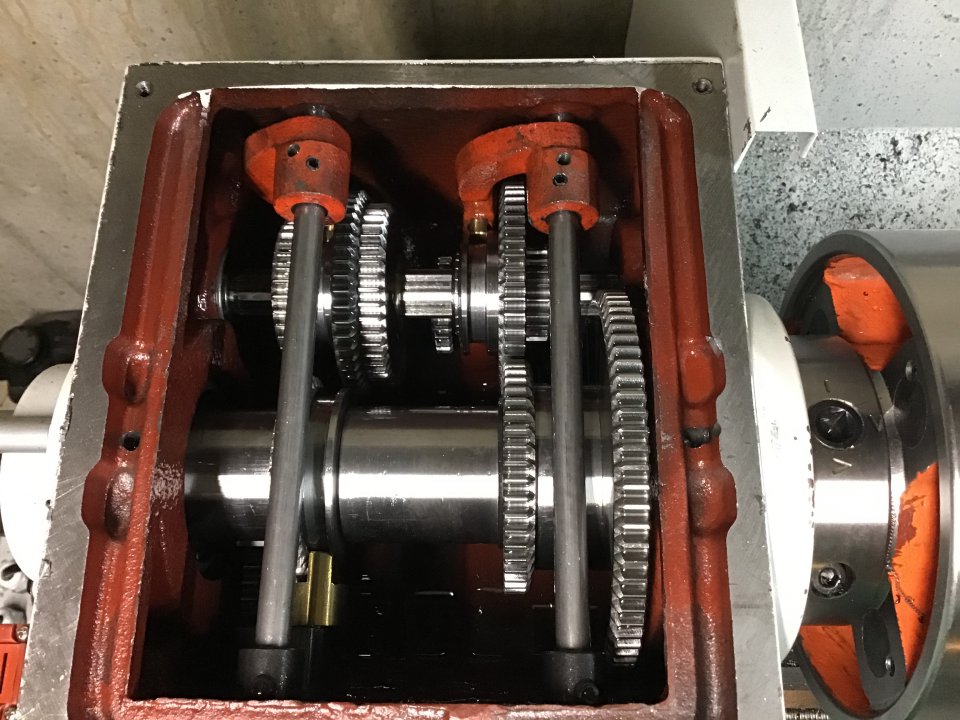

I don’t have an hour meter on the lathe, so not sure exactly how much it got used before the first oil change, I think it was about 20ish hours, but there was more metal filings in there than I expected. You can see wells on either side of the lubrication holes for the spindle bearings that catches debris before it gets into the bearings. There was a good layer in each well, so this highlights the importance of using an oil that does not suspend the metal articles in the oil, but rather will let them settle out. I opened up the cover again today after about another 30 ish hours of use and there was again a significant amount of metal particles in the collector wells. I think I might put my vibration analyzer on it and see if I find any gear faults that could be causing wear of the teeth that is not evident with a visual inspection.

If you want to use collets with a lever closer, you might not be able to get your tool close to the collet. The switches for forward and reverse are located next to the quick change gearbox and doesn’t allow the carriage to get closer than 2 inches from the spindle nose. If you use an adapter for the collet in the spindle bore, you would need to extend your part at least 2 inches to make a cut. A collet chuck will be more suitable for this lathe, or an extended nose collet adapter with the lever collet closer.

This is the three phase version and I installed a VFD. I did not install a speed pot since I wanted to try some different ideas first. I set it up on the high speed pulley position and added a switch that reduces the motor speed in half. This gives me all the nameplate speeds at the flip of a switch. I haven’t found the need to adjust the speeds via a pot yet, so still haven’t installed it. I also added a fast stop for threading since I do metric and can’t disengage the threading lever. Since threading is fairly low speed, a 0.5sec deceleration time works fine even with the high inertia of the four jaw chuck. I have been thinking about adding Mark’s proximity stop idea, I already had a sensor that would work, but I am going to try threading away from the chuck instead and see how I like that. I will need to creep up on a shoulder for starting the thread, but might be easier in the ling run. I never installed a jog switch, I like using the forward/reverse lever for that, and since my acceleration time is 5 seconds, it works really well as a jog. 5 seconds is a bit long for the acceleration, so I might get around to changing that to 3 seconds one of these days.

If you read my post about getting this lathe into my basement, then you saw the wooden stand I built. I have to admit I am surprised it has worked as well as I hoped. I expected to need to add additional weight to the stand, but so far have not needed to. I haven’t turned anything off balance yet, so that might show it’s limitations, but there have been zero modifications to it.

Overall I am very happy with this lathe and wouldn’t hesitate to recommend this to someone looking for this size lathe. I lucked out and bought before the big price increases, I’m not sure I would buy it today at current prices and lead times since there is usually something used available in my area. Even with having to replace spindle bearings, a used one would likely be cheaper, but like with Christmas chocolates, you never know what you are getting until you take a bite. My only regret with this lathe is not getting it sooner!

My first impressions were a bit mixed, I bought a Taiwanese lathe expecting it to be better than a Chinese made one, but some of the fits and finish were more Chinese looking. The bed casting was not fully machined like I expected, you can see in this first picture the roughness on the insides of the ways. This doesn’t affect the operation of the lathe, but it does make you take a closer eye to the rest of the machine.

The second problem I discovered was the gear cover was machined off center. You can see in this picture that the hole in the guard is not centered well at all around the spindle. It appears this was not set up properly when having the holes bored since the holes for the mounting studs are not centered in the recesses. There is just enough room to fit a spider without rubbing on the cover, but I will probably open this hole up a bit to give some more room.

This lathe comes with a 3 jaw chuck. I don’t know where the chuck was made since there are not any markings on it, but not impressed with it. The tapered bore for the D1-4 spindle is on the loose side, when loosening the camlocks, the chuck will fall off the spindle if you don’t hold it. My other chucks need a tap with a rubber mallet to break free. I might take a skim cut one of these days to get it to fit better, but since I don’t use it very much, I might just leave it for now. I tested the runout of the jaws using an endmill (the only ground item I had that I could chuck) and also with a cylindrical roller bearing inner ring about 80mm bore. The runout was 0.007” with one set of jaws

and 0.005” with the other set. It was repeatable when rotating the end mill and ring, so the runout is in the jaws and not the items being used. I expected better than that from Taiwan, Shars lists their Chinese chucks should have runout less than 0.003”, so I don’t think it unreasonable to have at least that. The serial number on the two sets of jaws was different, the jaws on my Bison chuck match the

serial number of the cuck body, so I called PM to inquire about them not matching. According to them, the serial number are for the jaws and are not meant to match a particular chuck. That might explain the runout.

Most of what I machine is metric, so I was glad to have a quick change gearbox that cuts so many metric threads with only a few changes in gears. But, I was very surprised one of the most common thread pitches was not included in the chart. M12 course thread is 1.75 and it is not in the thread tables at all, and 0.8 used for M5 was not there either, but I usually use dies for threads that size. I made a table with different gear combinations and found that using 32x40 gear combination gives me both of those threads.

Using the machine is a huge step up from the 9x20 Jet I started out on. Runout on the spindle barely moves my test indicator and the quality of the cut is excellent considering the size of the lathe. I have been using mostly carbide tooling and the lathe handles that very well. I use CCGT and DCGT for the most part and like it a lot.

I don’t have an hour meter on the lathe, so not sure exactly how much it got used before the first oil change, I think it was about 20ish hours, but there was more metal filings in there than I expected. You can see wells on either side of the lubrication holes for the spindle bearings that catches debris before it gets into the bearings. There was a good layer in each well, so this highlights the importance of using an oil that does not suspend the metal articles in the oil, but rather will let them settle out. I opened up the cover again today after about another 30 ish hours of use and there was again a significant amount of metal particles in the collector wells. I think I might put my vibration analyzer on it and see if I find any gear faults that could be causing wear of the teeth that is not evident with a visual inspection.

If you want to use collets with a lever closer, you might not be able to get your tool close to the collet. The switches for forward and reverse are located next to the quick change gearbox and doesn’t allow the carriage to get closer than 2 inches from the spindle nose. If you use an adapter for the collet in the spindle bore, you would need to extend your part at least 2 inches to make a cut. A collet chuck will be more suitable for this lathe, or an extended nose collet adapter with the lever collet closer.

This is the three phase version and I installed a VFD. I did not install a speed pot since I wanted to try some different ideas first. I set it up on the high speed pulley position and added a switch that reduces the motor speed in half. This gives me all the nameplate speeds at the flip of a switch. I haven’t found the need to adjust the speeds via a pot yet, so still haven’t installed it. I also added a fast stop for threading since I do metric and can’t disengage the threading lever. Since threading is fairly low speed, a 0.5sec deceleration time works fine even with the high inertia of the four jaw chuck. I have been thinking about adding Mark’s proximity stop idea, I already had a sensor that would work, but I am going to try threading away from the chuck instead and see how I like that. I will need to creep up on a shoulder for starting the thread, but might be easier in the ling run. I never installed a jog switch, I like using the forward/reverse lever for that, and since my acceleration time is 5 seconds, it works really well as a jog. 5 seconds is a bit long for the acceleration, so I might get around to changing that to 3 seconds one of these days.

If you read my post about getting this lathe into my basement, then you saw the wooden stand I built. I have to admit I am surprised it has worked as well as I hoped. I expected to need to add additional weight to the stand, but so far have not needed to. I haven’t turned anything off balance yet, so that might show it’s limitations, but there have been zero modifications to it.

Overall I am very happy with this lathe and wouldn’t hesitate to recommend this to someone looking for this size lathe. I lucked out and bought before the big price increases, I’m not sure I would buy it today at current prices and lead times since there is usually something used available in my area. Even with having to replace spindle bearings, a used one would likely be cheaper, but like with Christmas chocolates, you never know what you are getting until you take a bite. My only regret with this lathe is not getting it sooner!