-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pm 1228-vf-lb Lathe Preparations

- Thread starter Franko

- Start date

- Joined

- Feb 24, 2015

- Messages

- 1,382

Franko,

Not sure if someone else pointed this out but before you put the tool holders in the mill to find out if they are hardened try a file test, it won't cost you an end mill. The file will be fine also.

Mark

Yup, Mark. I learned to do that after trying to mill those QCTP holders. That was a learning experience I won't forget.

I learn best by screwing up most times.

- Joined

- Feb 8, 2014

- Messages

- 11,177

Thanks Ron, that's useful information.

I've attempted engaging the half-nut while it is running, but about half the time there is a little snag and it engages a little off the mark. It won't hit the zero exactly even when it isn't running.

The gear is not exactly lined up with the dial, on some machines it is possible to adjust that. Other are just pinned in place. The only solution in that case is to make a new witness mark where the 0 actually lines up.

- Joined

- Dec 8, 2013

- Messages

- 2,651

More than odd: suspicious. 20 divisions makes no sense for a threading diat for an 8TPI screw. How many teeth does the gear have and what is its pitch?Franko

A correct size shim between the thread dial and the carriage should cause the half nuts to close directly on one of the lines. Even so if you have the correct thread dial with the correct gear for an 8tpi leadscrew the half nuts should engage at exactly the same point on the dial every time- same distance from zero. If not there is a problem with the dial. Does the dial mount on a pivot so it can easily be disengaged without total removal? If so do you do you have the dial gear snugged up to the lead screw so there is no play? Given that your dial has 20 divisions this seem quite strange for a 8tpi leadscrew.

Ron

There should be a friction clutch so that you can adjust the zero.

Franko

Have you checked to see if the gear on the bottom and the dial on the top are firmly located on the shaft connecting them? Play between the gear &dial may explain the variability you are experiencing.

Do you know what the pin sticking out at position 17 is for? I would take the dial off and have a look to see if the alignment of the gear and dial can be tightened and adjusted for alignment. My metric Sieg SC4 has no threading dial and the one on the metric Sieg Runmaster is quite different so I cant help by comparing yours and mine

Ron

Have you checked to see if the gear on the bottom and the dial on the top are firmly located on the shaft connecting them? Play between the gear &dial may explain the variability you are experiencing.

Do you know what the pin sticking out at position 17 is for? I would take the dial off and have a look to see if the alignment of the gear and dial can be tightened and adjusted for alignment. My metric Sieg SC4 has no threading dial and the one on the metric Sieg Runmaster is quite different so I cant help by comparing yours and mine

Ron

- Joined

- Dec 8, 2013

- Messages

- 2,651

I would think that the pin is there so that you can rotate the dial on the friction clutch to align the zero.

- Joined

- Feb 24, 2015

- Messages

- 1,382

I would think that the pin is there so that you can rotate the dial on the friction clutch to align the zero.

I'm guessing that's what it is for, John. I haven't had much time to fool with it as paying work is demanding most of my attention right now.

Last edited:

- Joined

- Aug 12, 2013

- Messages

- 858

But it does make sense if it is a metric threading dial. The instructions that Franko posted are for a metric thread dial (although I find it difficult to believe that you would thread at 0 for all this threads).More than odd: suspicious. 20 divisions makes no sense for a threading diat for an 8TPI screw.

Does the dial actually seem to mesh right with the leadscrew?

Maybe they accidentally installed the metric dial face on the imperial thread dial. After all, they have been known to "accidentally" install a metric leadscrew on a lathe spec'd to be imperial.

- Joined

- Feb 24, 2015

- Messages

- 1,382

I don't think so, Tim. The threading dial on the Grizzly is identical. The gear meshes fine with the lead screw.

The data sheet Matt sent me says don't use the dial for metric threading.

The zero on the dial is one of the marks that doesn't exactly line up with the half-nut engaged. Some of the other marks like up perfectly. :-\

I'm definitely no authority on chasing dials, but I've never seen one with 20 marks.

The dial face doesn't seem to have any clutch or detents. It is held on with a screw and there is a spring under it. It will turn with the handle about a half turn. I was able to line it up on zero that way with the half-nut engaged.

Matt said he isn't happy with the dial and is negotiating with the factory to modify it.

The data sheet Matt sent me says don't use the dial for metric threading.

The zero on the dial is one of the marks that doesn't exactly line up with the half-nut engaged. Some of the other marks like up perfectly. :-\

I'm definitely no authority on chasing dials, but I've never seen one with 20 marks.

The dial face doesn't seem to have any clutch or detents. It is held on with a screw and there is a spring under it. It will turn with the handle about a half turn. I was able to line it up on zero that way with the half-nut engaged.

Matt said he isn't happy with the dial and is negotiating with the factory to modify it.

- Joined

- Dec 31, 2013

- Messages

- 327

As others have stated, the face on your dial is weird for a imperial threads, usually there is only 4 numbers and 4 halfs for a total of 8 marks.

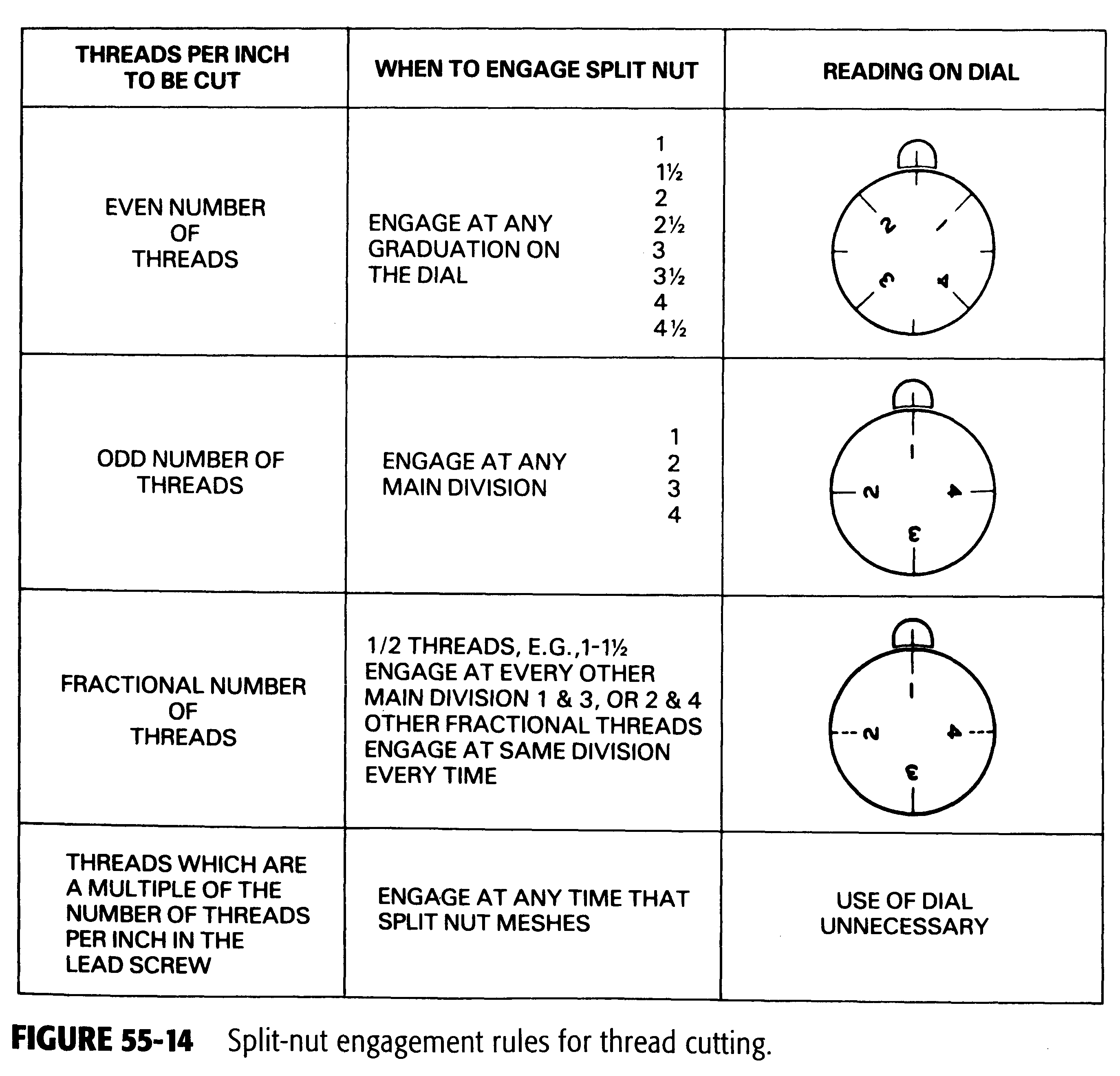

Using a threading dial is actually pretty easy and it's certainly faster than winding the lathe back each time. Here's a chart from a textbook that explains it pretty clearly.

I'm not sure, but I think this information is generic for any lathe with an imperial lead screw. I know it works on my SB 10K, whose threading dial looks exactly like the this.

As you can see, it's really easy to remember if you just grab a number each time as you are covered for both odd and even number of threads.

Using a threading dial is actually pretty easy and it's certainly faster than winding the lathe back each time. Here's a chart from a textbook that explains it pretty clearly.

I'm not sure, but I think this information is generic for any lathe with an imperial lead screw. I know it works on my SB 10K, whose threading dial looks exactly like the this.

As you can see, it's really easy to remember if you just grab a number each time as you are covered for both odd and even number of threads.