Hi, I just picked up a new (still in original box) 5x6 King horizontal bandsaw Off Kijiji yesterday. I assembled it and adjusted everything and it seems to be working quite well.

i have read that a quality blade is money well spent and I will need a spare regardless. I realize it’s not ideal but I would like to order a blade that will cut both mild steel and aluminum because 99% of my cutting will be:

1) mild steel; flats, plate, angles (3/8” thick max) and solid rounds typically < 1” and the odd pipe up to say 4”

2) aluminum same as above except no pipe.

speed is not really an issue so if it’s on the slower side that’s ok this is for fun not production.

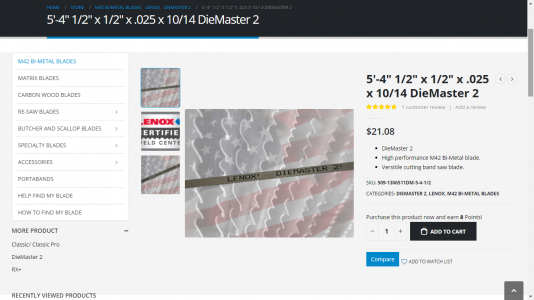

from what I have read both Starrett and Lenox make quality blades

i have read that a quality blade is money well spent and I will need a spare regardless. I realize it’s not ideal but I would like to order a blade that will cut both mild steel and aluminum because 99% of my cutting will be:

1) mild steel; flats, plate, angles (3/8” thick max) and solid rounds typically < 1” and the odd pipe up to say 4”

2) aluminum same as above except no pipe.

speed is not really an issue so if it’s on the slower side that’s ok this is for fun not production.

from what I have read both Starrett and Lenox make quality blades

Attachments

Last edited: