- Joined

- Feb 2, 2013

- Messages

- 3,957

My brother is an electrician.

he uses knockout punches for work daily.

he came across a malfunctioning hydraulic punch that was eventually given to him.

the punch is quite used.

the pins that secure the actuator handle and frame were worn through.

my brother asked if i could make new pins

he repaired the other things, and rebuilt the cylinder

i said, yep! sure can

he got me the pin dimensions, so i made new ones from 303 stainless as a test

if the 303 holds up, i won't change anything.

if it doesn't hold up, i'll consider O1 tool steel.

here are the pins before length trim.

the stock was .250" 303 stainless

the pins were made about .250" longer than necessary, then parted to size

i cross-drilled the pins on my drill press.

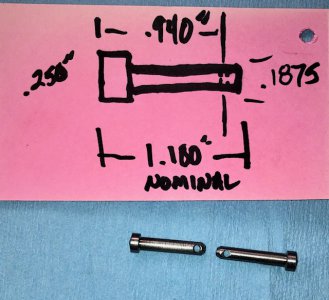

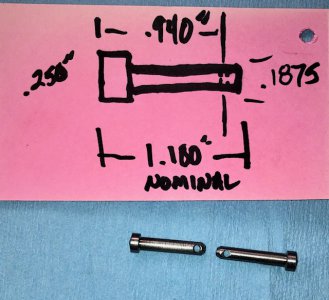

here are the finished pins with the sketch

we'll see how they last

he'll be reassembling the unit soon!

i'll post the results....

he uses knockout punches for work daily.

he came across a malfunctioning hydraulic punch that was eventually given to him.

the punch is quite used.

the pins that secure the actuator handle and frame were worn through.

my brother asked if i could make new pins

he repaired the other things, and rebuilt the cylinder

i said, yep! sure can

he got me the pin dimensions, so i made new ones from 303 stainless as a test

if the 303 holds up, i won't change anything.

if it doesn't hold up, i'll consider O1 tool steel.

here are the pins before length trim.

the stock was .250" 303 stainless

the pins were made about .250" longer than necessary, then parted to size

i cross-drilled the pins on my drill press.

here are the finished pins with the sketch

we'll see how they last

he'll be reassembling the unit soon!

i'll post the results....