Yes, a CNC lathe is the easiest way to do this. A bar fed lathe would be the fastest for production if you have 12 or 20 foot bars. For 4 ft bars, a pull feed set up on the tool turret would be the best.

''Perfect precision'' is impossible, but you can get as close as it is possible to measure. You have to specify the +/- tolerance required, keep in mind that the tighter the tolerance, the higher the cost. +/- 0.005'' is easy, +/- 0.0005'' would be difficult to hold in nylon. Once the program and tooling dialed in, the repeatability should be quite good. Actual chip making time per part should be in the 2 minute(ish) range. The setup and CAM time will proabaly take an hour or so.

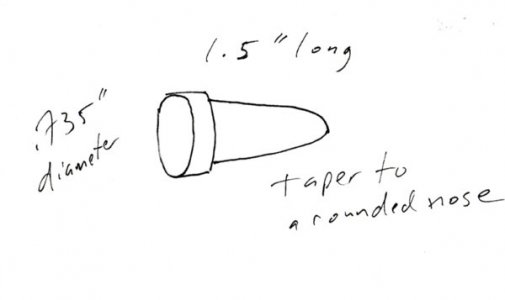

From the thread title, do I understand that you are interested in buying a CNC lathe? A CAD drawing would be the best, a 3D print file would not work well for lathe work.

I didn't send an email to you because my lathe is down at the moment. I'll have my CNC lathe up and running in a few days if you can wait. I'm pretty sure that there are other members here that would be able to do this for you.