- Joined

- Oct 13, 2014

- Messages

- 9,687

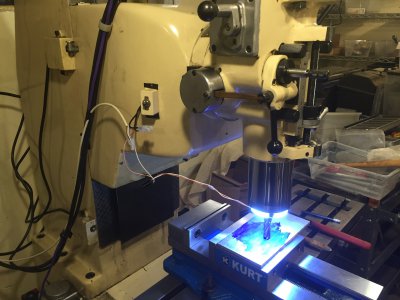

So I finally got my new mill up and running, It will eventually be cnc'd but in the meantime I wanted to add some features to make it easier to use.

The first Items I added were the pushbutton control switches and the auto reverse that keeps the spindle rotation correct in accordance with the Forward & Reverse buttons when switched into either High or Low gear range. That project was posted Here: http://www.hobby-machinist.com/thre...y-pushbutton-switch-update.39157/#post-342502

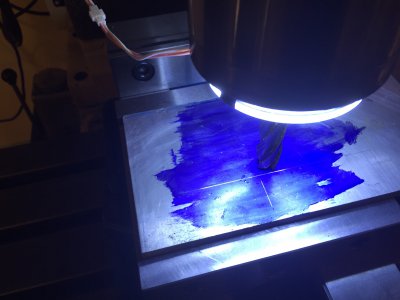

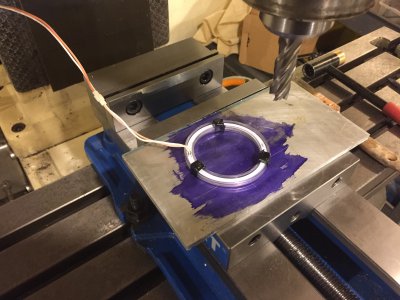

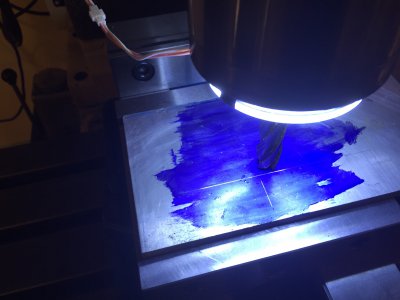

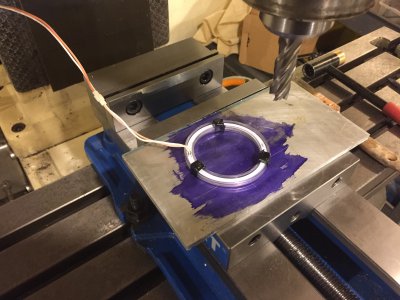

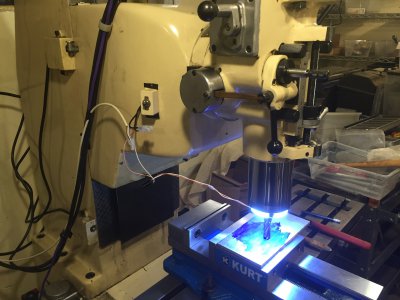

Next, I found these "Angel Eyes" or "Halo" LED ring lights on eBay, normally used for adding some bling to a Beamer or street racer. I thought they would make a perfect spindle light.

I used some small neodymium magnets taped to the ring as a temporary mounting. I will machine a permanant mount that will also incorporate the reader for the MachTach (to be added soon).

I also used magnets to temporally mount the switch to the head. The light works great, eliminates any shadows and really accentuates scribed lines.

Some other items I'm going to add:

Quill feed-lever mounted reverseing button,for tapping.

DRO.

Coolant system.

Maybe a new paint job, metal-flake candy apple red?

The first Items I added were the pushbutton control switches and the auto reverse that keeps the spindle rotation correct in accordance with the Forward & Reverse buttons when switched into either High or Low gear range. That project was posted Here: http://www.hobby-machinist.com/thre...y-pushbutton-switch-update.39157/#post-342502

Next, I found these "Angel Eyes" or "Halo" LED ring lights on eBay, normally used for adding some bling to a Beamer or street racer. I thought they would make a perfect spindle light.

I used some small neodymium magnets taped to the ring as a temporary mounting. I will machine a permanant mount that will also incorporate the reader for the MachTach (to be added soon).

I also used magnets to temporally mount the switch to the head. The light works great, eliminates any shadows and really accentuates scribed lines.

Some other items I'm going to add:

Quill feed-lever mounted reverseing button,for tapping.

DRO.

Coolant system.

Maybe a new paint job, metal-flake candy apple red?