- Joined

- Oct 28, 2020

- Messages

- 542

Hey Guys

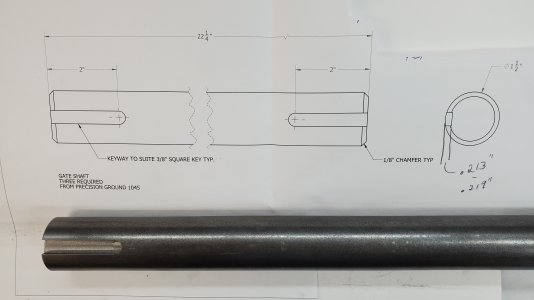

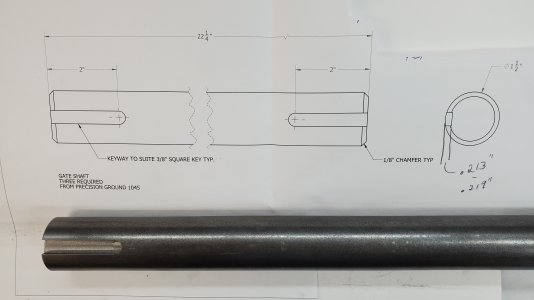

Today in my tiny shop my company worked on a paying gig. A simple shaft. A 1045 shaft with a keyway on each end. Nothing to it right?

Minimum investment for required equipment aprox $10k

I'm not complaining, I'm just saying a lot goes into even the simplest of jobs.

Enjoy your shop time

Today in my tiny shop my company worked on a paying gig. A simple shaft. A 1045 shaft with a keyway on each end. Nothing to it right?

- email supplier ask for quote wait

- get price /order stock

- pay for stock

- wait two days

- drive to suppler 40 minutes, get stock (during pandemic)

- clean stock rags/break cleaner

- swap out collet chuck for three jaw

- face first end

- chamfer first end

- rough cut to length in band saw

- face second end

- chamfer second end

- remove mill vice

- set up stock on mill table

- find end of work

- find centre of work

- set up mill table stop

- mill key way four passes

- flip work

- mill key way four passes

- debur

- clean up lathe

- clean up mill

- reinstall/tram vice

- create delivery slip

- create invoice

- deliver

- wait 30-40 days to get paid

- give 1/3 of any profit to government

Minimum investment for required equipment aprox $10k

I'm not complaining, I'm just saying a lot goes into even the simplest of jobs.

Enjoy your shop time

Last edited: