A

Alan H.

Forum Guest

Register Today

I installed a “one-shot” lubricator for the quick change gears on my PM1340GT lathe. Others have done this upgrade as well and mine is just another example of how it can be done. A couple of my buddies that have plowed this ground before were extremely helpful in sharing their insights with me.

Here are a couple of photos of the finished install:

Some of the details:

I used a ½” round brass manifold with 1/8” OD (1/16” ID) copper tubing distributors. These small distributors were threaded and fit into the manifold. The pump I used is a Trico PM2000 which is an 8cc pump. I used 3/16” ID Tygon tubing from the pump to the manifold.

One challenge was to adapt the pump to the Tygon tubing. I made the tubing adapter for the discharge of the pump. It is an 8 mm -1 male to 3/16” hose barb.

The ½” OD manifold was through drilled to ¼” ID and the end was closed by solder sweating a brass plug into it and then machining it flush. The manifold was drilled and tapped with #6 -32 holes for the distributor tubes. The tubes/pipettes were threaded to secure them to the manifold and were different lengths to feed the oil ports on the distributor. The manifold is held in place with a brass clip.

The Trico PM2000 pump and custom fitting:

The fitting I made along with the HSS tool I ground to make the barb end:

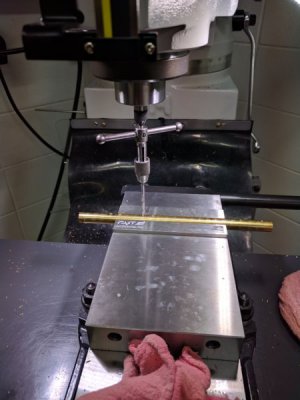

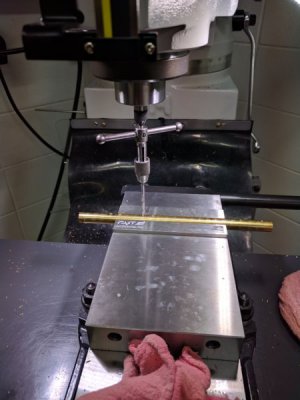

Tapping the manifold for the distributors:

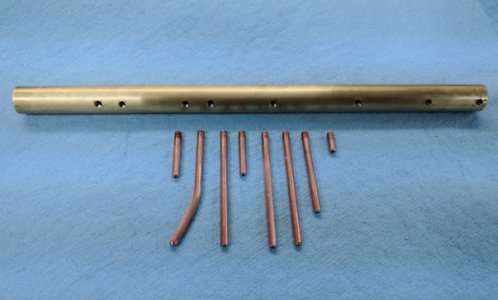

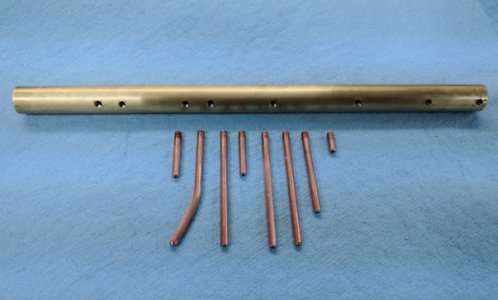

Manifold parts ready for assembly:

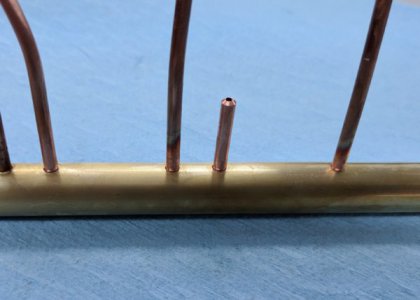

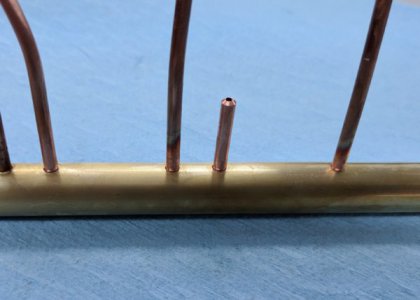

Tubes threaded into the manifold:

My goal with the concept I used was to be able to see how this system works and make any adjustments as necessary. I am satisfied with the outcome. The purpose of the attached video is for you to see how the pumping action works:

My hope is this thread may help others who might want to do such an upgrade. Therefore I am hoping other folks who have done an upgrade like this may share their work on this thread as well.

Here are a couple of photos of the finished install:

Some of the details:

I used a ½” round brass manifold with 1/8” OD (1/16” ID) copper tubing distributors. These small distributors were threaded and fit into the manifold. The pump I used is a Trico PM2000 which is an 8cc pump. I used 3/16” ID Tygon tubing from the pump to the manifold.

One challenge was to adapt the pump to the Tygon tubing. I made the tubing adapter for the discharge of the pump. It is an 8 mm -1 male to 3/16” hose barb.

The ½” OD manifold was through drilled to ¼” ID and the end was closed by solder sweating a brass plug into it and then machining it flush. The manifold was drilled and tapped with #6 -32 holes for the distributor tubes. The tubes/pipettes were threaded to secure them to the manifold and were different lengths to feed the oil ports on the distributor. The manifold is held in place with a brass clip.

The Trico PM2000 pump and custom fitting:

The fitting I made along with the HSS tool I ground to make the barb end:

Tapping the manifold for the distributors:

Manifold parts ready for assembly:

Tubes threaded into the manifold:

My goal with the concept I used was to be able to see how this system works and make any adjustments as necessary. I am satisfied with the outcome. The purpose of the attached video is for you to see how the pumping action works:

My hope is this thread may help others who might want to do such an upgrade. Therefore I am hoping other folks who have done an upgrade like this may share their work on this thread as well.

Last edited by a moderator:

Your approach is certainly a lot more straight forward that my implementation (which is documented

Your approach is certainly a lot more straight forward that my implementation (which is documented