-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Odd tailstock attachment

- Thread starter TechNova

- Start date

- Joined

- Jun 7, 2013

- Messages

- 10,459

Frankenstock ---

- Joined

- Feb 26, 2014

- Messages

- 276

I have the same "chuck" for my Craftsman 12". It fits snuggly over the tailstock barrel and held with a set screw. I've used mine to hold a long tube that I couldn't get a center on. I'll try to get a pic tomorrow.

- Joined

- Nov 28, 2016

- Messages

- 2,805

It looks like it would be a useful method of supporting a workpiece where a center hole would not be wanted, or a length of tubing where it would be desirable to support it on the outside. It could also be used for larger tubing that would fit around the bearings, and the chuck jaws expanded outward to support the tubing from the inside.

Someone has chucked a dead center in it to use as a conventional live center rather than taking it off to install a live center in the quill.

-Bear

Someone has chucked a dead center in it to use as a conventional live center rather than taking it off to install a live center in the quill.

-Bear

- Joined

- Apr 23, 2018

- Messages

- 6,900

That looks like a good tool to use when you don't know whether to support the work or not.

- Joined

- Dec 9, 2021

- Messages

- 738

Atlas sold lathes that were specialized for refurbishing rollers from offset printing presses. Think newspapers.

These used the headstock and bed from the later 12" lathe, but were so different that it would be difficult to convert one to a conventional lathe.

I don't have any photos of one. I only saw photos of a couple on Craigslist, and parts from one in the flesh. The parts were owned by a fellow who converted the machine to make pool cues.

These used the headstock and bed from the later 12" lathe, but were so different that it would be difficult to convert one to a conventional lathe.

I don't have any photos of one. I only saw photos of a couple on Craigslist, and parts from one in the flesh. The parts were owned by a fellow who converted the machine to make pool cues.

- Joined

- Apr 23, 2013

- Messages

- 1,080

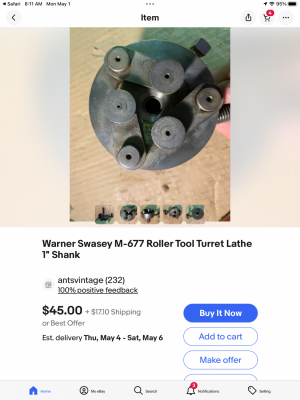

One of the first things I had to modify in 1953 was to repair gear shafts where the

center drill had walked off center. They had to be less than .002 runout. Then we started using this W&S tool that had three rollers and a center drill . You captured the shaft in the rollers. Then adjusted the rollers snug and centered or recentered the shaft and it was easy to get parts to print. This tool reminds me of that turret tool.

I still have a couple of these centering tools for my turret lathes. And I wish they had a tapered shank so that I could use them in my tailstock to steady long parts.

jimsehr

Attachments

Last edited:

- Joined

- Apr 23, 2018

- Messages

- 6,900

So do you call that a live center, or a dead center? I think it counts as live, because the outer race of the bearing is live to stay in contact with the surface of the part, even though the fixture itself does not rotate with the work.

It makes plenty of sense to me, but the original picture with the center chucked in it and the droopy tailstock extended makes it look like quack science.

It makes plenty of sense to me, but the original picture with the center chucked in it and the droopy tailstock extended makes it look like quack science.