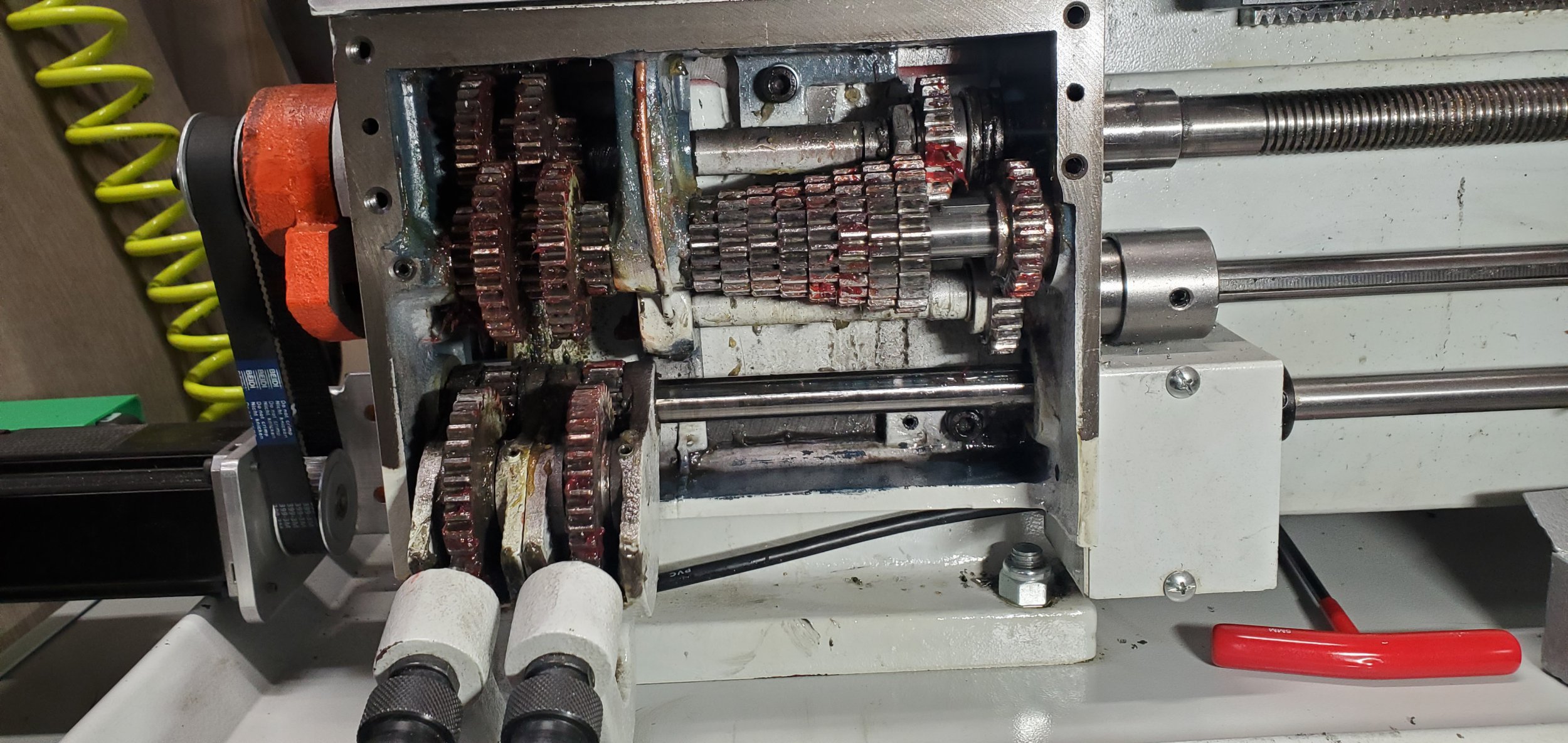

Randal, That very well could be what going on. It's not bad but it's more then I think there should be. I took the cover off to check things out, I don't see anything wrong, but the gears are looser than what I remember in a truck transmission.

The noise is kind a raddling sound if you will. It's more pronounced when I turn the feed rate up, or I think when I have it set for low number of TPI (I need to check that again to make sure that's when it happens).

Before the ELS: Being that I'm still learning, I haven't really moved the feed rate much off of the slower settings. I've cut a few different thread counts, nothing below 11 tpi.

After the ELS: I have played with different setting, feed rates, TPI changes and that's when I really noticed the gear noise. On the ELS setup I'm using gear selection D and 6 and I'm not sure I have had the lathe in that position before. So, I thought maybe something was up with those gears.

After looking things over I don't believe there is a problem, I think it is just the looseness / backlash in the gear train, and I think you are probably on to what is causing it to make noise.