- Joined

- Dec 5, 2017

- Messages

- 14

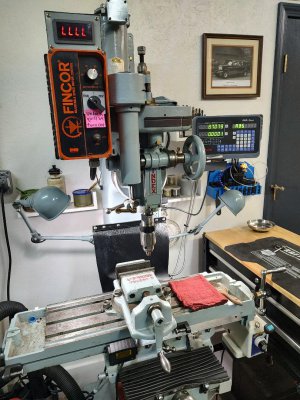

Just wanted to update you on a few new upgrades to my 40H Index mill I've made over the holidays. I installed a new DRO, (my first time) but now I'm wondering why I didn't install a 3-axis with a scale on the knee? I've thought about buying another 3-axis DRO unit and switching the existing 2-axis unit over to my 12" Atlas lathe, but I feel that might be a bit of an overkill for such a lowend machine. I also installed a much desired RPM gauge on top of the DC motor control which to my surprise, is a lot more accurate than my previous guessing method. I added a reversing drum switch to the contol box, and installed a new on/off switch replacing the 80+ year old stiff button switch I didn't feel comfortable with. The drum switch installation which came from China with no instructions, really hurt my brain trying to figure-out the wiring but after drawing it out on paper, (about 5 times) it went much smoother than I expected. I wasted a lot of time on You Tube but there wasn't much on there that related to my install so I bit the bullet and had to figure it out for myself. I have to admit, when I plugged it in to the outlet on the wall after my modifications I stood on a thick rubber mat, and I closed my eyes when I turned it on. Everything worked very well to my surprise. Now I need a few worthwhile projects to try everything out using the new upgrades. Once again for those new to the trade this only proves that you can do anything you desire if you only put your mind to it!! Jim Y.