hey guys, been playing with the lathe doing simple turning but would like to try threading but got a few questions.its more about the compound function really. im trying to understand why the compound needs to be set at 29.5 degrees for threading. if its like that and you use the compound screw to advance after each pass then it seems to me that each time you advance while at that angle i would be cutting into the thread and ruining it. seems like you would advance each pass with the cross feed instead of the compound therefore the 29.5 would mean nothing. what am i missing??????????

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

new to threading and have questions

- Thread starter pete1972

- Start date

- Joined

- Jan 22, 2011

- Messages

- 8,032

Since the standard UN thread is 60 degrees, and your tool is ground to 60 degrees, moving it along a 29.5 degree line into the cut throws the majority of the cut on the leading (Left) edge of the tool. Many people take this route believing that the cutting force is primarily on that edge and the trailing (Right) edge only cuts the 0.5 degrees left from the compound movement angle, yielding a better finish. This could be true since you can do better in some material with a positive rake, and you really can't practically grind both leading and trailing edges to cut with positive rake. The more positive the leading is, the more negative the trailing edge. If you are using a neutral rake tool, there really isn't as much difference, IMO. It is a point that many will argue, but straight in feed, 29.5 degree feed in.....they both have advantages that are sometimes determined by the machine and material.

If you are feeding in straight, with the cross slide as you mentioned, yes, the 29.5 degrees is immaterial since you won't be moving the compound. In that case, the chipload would be fairly equal on both flanks of the thread, depending on the grind of the tool. Make sure you are understanding that the 29.5 degrees is from the face of the part, not the axis. Not all compounds are marked from the same reference.

If you are feeding in straight, with the cross slide as you mentioned, yes, the 29.5 degrees is immaterial since you won't be moving the compound. In that case, the chipload would be fairly equal on both flanks of the thread, depending on the grind of the tool. Make sure you are understanding that the 29.5 degrees is from the face of the part, not the axis. Not all compounds are marked from the same reference.

- Joined

- Nov 21, 2010

- Messages

- 1,602

Not being rude Pete what your missing is dont question the teacher. This has been the rule of thumb for 100 yrs. Allthough some prefer feeding straight in which is ok. But

when you have to do a lot of threading, for me its the thread stop and feed with the compound because you get a fine feed using the compound. No need to get into the math

as far as compound feed - just go with it and sneek up to it. Don't worry after you do a couple hundred thread jobs all the math goes away you will get into the look listen

and feel mode. Be patient with yourself it will come but not overnite and with all my overnites I can just look at a thread and tell you all about it with no charts no math

because I've done enough of them. Hope this helps little..however I'm old school and I am now older than the school I went to.

sam

when you have to do a lot of threading, for me its the thread stop and feed with the compound because you get a fine feed using the compound. No need to get into the math

as far as compound feed - just go with it and sneek up to it. Don't worry after you do a couple hundred thread jobs all the math goes away you will get into the look listen

and feel mode. Be patient with yourself it will come but not overnite and with all my overnites I can just look at a thread and tell you all about it with no charts no math

because I've done enough of them. Hope this helps little..however I'm old school and I am now older than the school I went to.

sam

- Joined

- Apr 23, 2011

- Messages

- 2,476

Sam I have to disagree.If we all followed in the footsteps of our teachers without question then we would all be educated to the same tune and nobody would have discovered the earth was in fact, round.Not being rude Pete what your missing is dont question the teacher.

Pete,

the following is a bit long winded, (it is from another post) but have a read and see if it makes sense.

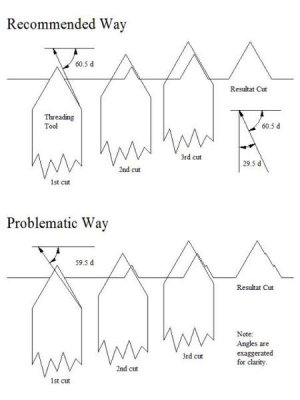

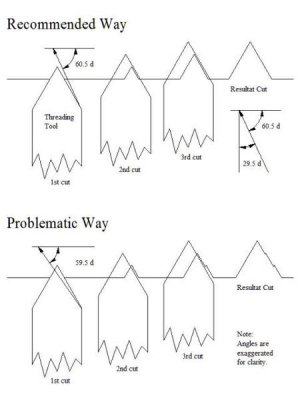

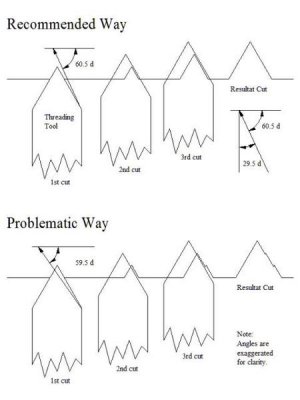

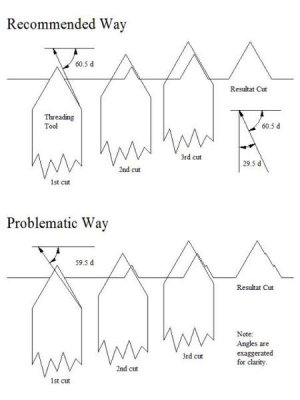

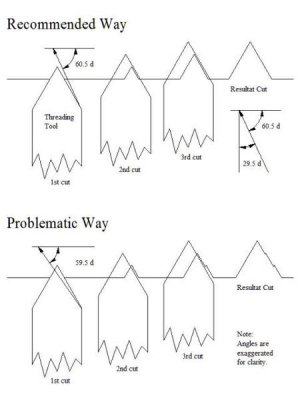

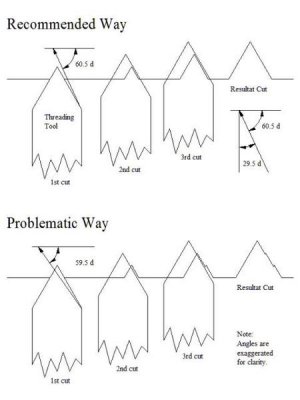

Any questions, please askAs I suggested, you are missing the point about the relationship of movement established by having the compound set at 29.5*. Yes the tool form does establish the thread profile, but by having the tool cut progress at not quite 30* it takes the majority of the cut on the left (leading) edge, and the right, (trailing) edge takes very light cuts. In the pic the V cut by the tool form is 60* but as can be seen by the dashed line the movement of the tool when set at less than 30* causes it to move in a marginal amount as well as left a greater amount. Causing the tool to take a heavier cut on the leading edge and a very fine cut on the trailing edge.

View attachment 68387

As the sketch illustrates, having the tool move in at an angle less than 30* we do maintain the included angle of the form tool it just cuts less on the trailing edge. If the angle is set at or greater than 30* then the tool will only cut on the leading edge as it is sliding along or moving away from the trailing edge as it cuts progressively deeper, and this will result in a staircase effect on the trailing edge.

No not everyone does teach or support it, but their may be more reasons than because you think it is myth. Cutting tools are much better nowadays, CNC machines may cut threads using different methods, the size and rigidity of the lathe may not permit heavier straight in cutting, the quality of the finished product may or may not have a bearing on the method, single point threading in my opinion is a dying art as the cheapness and availablity of threaded products can outweigh the cost of a production shop spending the time making something they can probably buy cheaper.

The point of it is to eliminate the staircase effect and reduce tool loading. The drastic and perceivable difference of leaving the staircase effect is that the right thread flank in most cases is the load bearing side of the thread and needs to be as smooth and accurate as possible.

As I suggested in my reply earlier, you are not thinking about the progression of the tool. We are using the compound angle to establish a small amount of y axis movement and a greater amount of x axis movement resulting in cutting on both sides of the tool.

Perhaps in an ideal situation with every angle perfect, and we are talking measuring in seconds of degrees here then it

1) may be possible to have your tool ground to 60* +/- 0.0000

2) set your tool to be perpendicular to the work 90* +/-0.0000

3) set your compound to 30* +/-0.0000

and then have your tool sliding in perfectly parallel on the right flank and only cutting on the left flank.

Provided our machine is also perfect and has no defect.

But as we are not working to these levels of precision then with a

1) hand ground HSS tool, “eyeballed” for accuracy in a fish tail gauge

2) said fish tail gauge then “eyeballed” for presenting the tool at 90* to the work

3) compound “eyeballed” for 30*

then I would suggest that if anything is off 1 way or the other then the compound will be presenting the tool at something less or more than 30* +/- 0.0000.

Then we also need to take into allowance our worn dovetails, gibs backlash and other general wear on our workshop lathe.

As I doubt there would be many machinists, if at all a single 1 who gets their threading tools ground to the nth degree of perfection, and then uses lasers to ensure that they have the tool presented at 90* to the work and also uses a vernier protractor to establish that they have set the compound to 30* then I am of the opinion that “something in the realm of a bit less than 30*” is probably optimal.

Cheers Phil

Cheers Phil

- Joined

- Nov 21, 2010

- Messages

- 1,602

Oh you are right Phil, I looked out the window all through high school years, and when I walked out the door I clicked my delete button. My teachings came from old time

machinist mentors not in public schools....rather the school of hard knocks.....a big LOL

machinist mentors not in public schools....rather the school of hard knocks.....a big LOL

- Joined

- Aug 15, 2013

- Messages

- 2,514

Great post, Phil.

Pete, in addition to Phil's explanation, this illustration helped me get a better handle on the 29.5 degree way of thinking.

(Note: Remember the 29.5 degree compound angle is measured from the X (cross slide) axis.) HTH.

(Edited to correct axis reference. Thanks, John. My bad.)

Tom

Pete, in addition to Phil's explanation, this illustration helped me get a better handle on the 29.5 degree way of thinking.

(Note: Remember the 29.5 degree compound angle is measured from the X (cross slide) axis.) HTH.

(Edited to correct axis reference. Thanks, John. My bad.)

Tom

Last edited:

great info guys!!!!!!!! really helps me sort things out. have another question if i may. how do i determine thread depth. i have a thread gauge in my tap and die set but i never see people using them when they do videos. is this just because of experience and just knowing?????? or just keep checking till the nut screws on? which would be a problem if you didn't have a nut at the time of threading. so many questions! but this will make me a wiser man pete

- Joined

- Dec 8, 2013

- Messages

- 2,651

I believe that is conventionally the X axis on a lathe, with the Z axis being the spindle axis.

- Joined

- Mar 11, 2012

- Messages

- 124

Pete,

I had a lot of the same questions when i started machining. Watch the threading video on YouTube by the lazy machinist. By far it's the best explanation I've seen so far on the subject and talked a lot about the reason for an angle less than 30 degrees.

I had a lot of the same questions when i started machining. Watch the threading video on YouTube by the lazy machinist. By far it's the best explanation I've seen so far on the subject and talked a lot about the reason for an angle less than 30 degrees.