I have a CNC'd G0704.

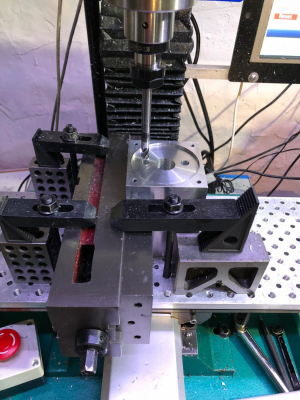

You need a decent 4" milling vise. Decent, not crazy. I bought a $150 import one that is plenty good for me. A set of parallels would be a really good purchase to go with the vise. Don't go crazy, a set of 5 sizes, 3" across has lasted me 10 years. I wouldn't get anything more than a 10 size 4" wide parallels. The CNC style vises (flat sides) are nice because you can put them on their sides to gain 2" additional Z height on tall parts. Not commonly needed, but the G0704 is limited to 9" of Z clearance to the table.

This is the minimum I'd get:

https://www.shars.com/products/workholding/vise/4-x-3-93-lock-down-precision-milling-machine-vise-1

Better:

https://www.shars.com/products/workholding/vise/4-440v-cnc-milling-machine-vise-0-0004-1

Best:

https://www.glacern.com/gpv_412

If machining steel, stick to 1/4" or smaller endmills. If aluminum, use 3/8" or smaller. These machines have relatively low rigidity and can't utilize larger cutter very well. They work, but you can machine faster with a smaller tool. HSS is fine for manual work. Polished carbide endmills give top performance in milling aluminum with great finish.

You'll need a drill chuck. I prefer a 1/32-1/2" on a 3/4" shank. Put it in a 3/4" R8 collet. Saves some tool change height. I prefer keyless over keyed, but both are fine. You need to buy the shank separately for most chucks.

www.shars.com

You'll eventually want a 115pc drill index. This is used on both the mill and lathe. These are expensive so there are two trains of thought. Buy a cheap index ($200) and replace the drills with high end drills as they break. Or spend more ($400) and get a good set to start with. I did the former, but I find I am not good about buying the replacements and they are missing when I need them.

www.shars.com

A clamping kit will likely be needed to hold your vise. It will also become invaluable when you move away from only machining square stock in a vise. 3/8-16 is the bolt size you need for the table. You may need to mill the T-nuts a smidge to get them to fit correctly. Some fit fine, some don't.

58 Pc Pro-Series 7/16" T-Slot Clamping Kit Bridgeport Mill Set Up Set 3/8-16 - - Amazon.com

www.amazon.com

Fly cutter is optional. Just faster than facing with endmills. It really exacerbates any issues with column tram.

You'll need these items for measuring (at a minimum): 6" calipers, 0.0005" Dial test indicator, probably a 1" micrometer. Measuring tools are the ONLY thing I go out of my way to buy name brand. They last much longer and just give you a better quality of life.

www.shars.com

This is the gold standard:

https://www.mscdirect.com/browse/tnpla/06442826?cid=ppc-google-Smart+Shopping+-+MCO+-+Measuring+&+Inspecting&mkwid=|dc&pcrid=534899372863&rd=k&product_id=06442826&gclid=CjwKCAjw-8qVBhANEiwAfjXLrsqdk6q09iowoNgtg4ziIWEG2_iYwQlpFzxMS7HIuh98psXo61s5oRoCNjkQAvD_BwE&gclsrc=aw.ds

I wouldn't recommend any other caliper than these:

https://www.amazon.com/Mitutoyo-Advanced-Absolute-Digital-Caliper/dp/B00IG46NL2?th=1

EDIT: Add an edge finder to the list. I prefer an electronic one with a spring loaded ball tip, but any garden variety works. The ball tip lets you center on curved surfaces, less common but handy.