Hi All,

I am a long time lurker but I think first time posting. Reason for that is I dont know much so have nothing to contribute! The truth hurts. I am not totally new to machining but still dont know much.

Ill start off by telling a bit about myself. We have a company that makes metal signs, gates, railing panels, etc. When it comes to the machining side we have a Bridgeport milling machine and had that Sheldon lathe which has now been replaced with this one. Both machines are used for paying jobs but mostly in the course of making things that have to do with the other stuff we make that has to do with signage or whatever. Ive cut keyways for customers and turned some various jobs for folks but we are by no means a real machine shop. I guess you could call us a shade tree machine shop. Or something like that.

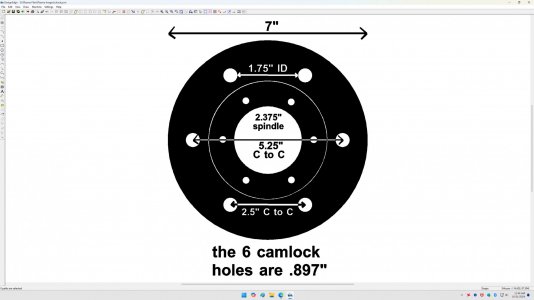

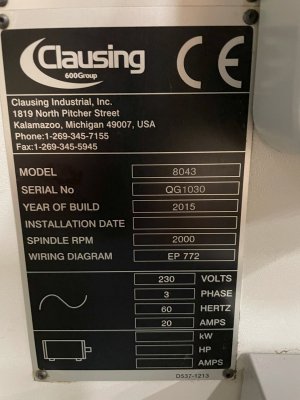

I just sold a Sheldon 56" lathe which was my first one and bought a Clausing 8043 from an auction. It has about 2500 hours on it. The only problem is it did not come with a chuck. A machinist friend of mine brought over a D1-6 chuck but it was too small so I called clausing and they told me it should take a D1-6 chuck. I took some measurements as can be seen in the picture I drew up. The measurements arent exact but pretty close. I was hoping someone could take a look at the measurements and the lathe if it helps and let me know what size of chuck you think this takes so I can order up the right one. Im wanting to get a 12" 3 jaw but need to make sure it fits the cam locks.

The only problem is it did not come with a chuck. A machinist friend of mine brought over a D1-6 chuck but it was too small so I called clausing and they told me it should take a D1-6 chuck. I took some measurements as can be seen in the picture I drew up. The measurements arent exact but pretty close. I was hoping someone could take a look at the measurements and the lathe if it helps and let me know what size of chuck you think this takes so I can order up the right one. Im wanting to get a 12" 3 jaw but need to make sure it fits the cam locks.

Id also did not come with the DRO screen. They took that as well. It does have ACU-RITE scales on it so just needs the screen which Ill pick up one of these days. Chuck comes first though!

Any help would be greatly appreciated.

Josh

I am a long time lurker but I think first time posting. Reason for that is I dont know much so have nothing to contribute! The truth hurts. I am not totally new to machining but still dont know much.

Ill start off by telling a bit about myself. We have a company that makes metal signs, gates, railing panels, etc. When it comes to the machining side we have a Bridgeport milling machine and had that Sheldon lathe which has now been replaced with this one. Both machines are used for paying jobs but mostly in the course of making things that have to do with the other stuff we make that has to do with signage or whatever. Ive cut keyways for customers and turned some various jobs for folks but we are by no means a real machine shop. I guess you could call us a shade tree machine shop. Or something like that.

I just sold a Sheldon 56" lathe which was my first one and bought a Clausing 8043 from an auction. It has about 2500 hours on it.

The only problem is it did not come with a chuck. A machinist friend of mine brought over a D1-6 chuck but it was too small so I called clausing and they told me it should take a D1-6 chuck. I took some measurements as can be seen in the picture I drew up. The measurements arent exact but pretty close. I was hoping someone could take a look at the measurements and the lathe if it helps and let me know what size of chuck you think this takes so I can order up the right one. Im wanting to get a 12" 3 jaw but need to make sure it fits the cam locks.

The only problem is it did not come with a chuck. A machinist friend of mine brought over a D1-6 chuck but it was too small so I called clausing and they told me it should take a D1-6 chuck. I took some measurements as can be seen in the picture I drew up. The measurements arent exact but pretty close. I was hoping someone could take a look at the measurements and the lathe if it helps and let me know what size of chuck you think this takes so I can order up the right one. Im wanting to get a 12" 3 jaw but need to make sure it fits the cam locks.Id also did not come with the DRO screen. They took that as well. It does have ACU-RITE scales on it so just needs the screen which Ill pick up one of these days. Chuck comes first though!

Any help would be greatly appreciated.

Josh