Hi Everyone,

Well, after a year of watching YouTube videos on machining, CNC milling, and so on, I made the plunge.

So far, I have purchased an Eventherm 22" Kiln (for heat treating knives), a Busy Bee Cx-601 Mill, BB CX-701 Lathe and used 12x6 Surface Grinder (same as the Grizzly G5963)

My first task was to replace the unfriendly tool post holder on the lathe (holds 4 tools, but each needs to be manually shimmed...no thanks). Unfortunately, the chose non-standard mount scheme...vs. The more standard wide t-slot method.

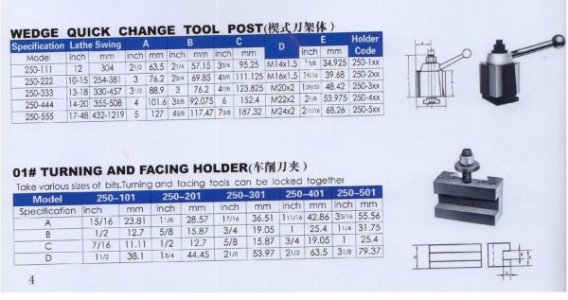

So, my first turning projects was to make a new tool post stud adapter...It was bit stressful using the lathe to make a part for the lathe...need to tear apart the compound to check the fit. Well, it all worked out. Put on a AXA wedge style holder purchased from Accusize (Canadian web retailer)

I also had to mill off about 1/8" on the compound "column" in order to allow the use of 1/2" tool holders, otherwise I would not be able to get the tools inline with the center of rotation.

All worked out (machining cast iron was really cool).

Here are a few pics. I had to reduce the thickness of the nuts (yah surface grinder) and then make a custom wrench (did not want to grind down one from the set). Really enjoyed the mods.

Sorry for the long intro post.

Look forward to hearing from you guys.

Cheers,

Al

Well, after a year of watching YouTube videos on machining, CNC milling, and so on, I made the plunge.

So far, I have purchased an Eventherm 22" Kiln (for heat treating knives), a Busy Bee Cx-601 Mill, BB CX-701 Lathe and used 12x6 Surface Grinder (same as the Grizzly G5963)

My first task was to replace the unfriendly tool post holder on the lathe (holds 4 tools, but each needs to be manually shimmed...no thanks). Unfortunately, the chose non-standard mount scheme...vs. The more standard wide t-slot method.

So, my first turning projects was to make a new tool post stud adapter...It was bit stressful using the lathe to make a part for the lathe...need to tear apart the compound to check the fit. Well, it all worked out. Put on a AXA wedge style holder purchased from Accusize (Canadian web retailer)

I also had to mill off about 1/8" on the compound "column" in order to allow the use of 1/2" tool holders, otherwise I would not be able to get the tools inline with the center of rotation.

All worked out (machining cast iron was really cool).

Here are a few pics. I had to reduce the thickness of the nuts (yah surface grinder) and then make a custom wrench (did not want to grind down one from the set). Really enjoyed the mods.

Sorry for the long intro post.

Look forward to hearing from you guys.

Cheers,

Al