Hello good people! I have been coming to the forum for a a few days now looking for some troubleshooting tips and I had to sign up. I own a force international at-300-2 3 in 1 lathe/mill/drill. Its one of those machine made by a bunch of manufacturers. This machine is older but a littler beefier then the new ones available having MT4/MT3 tapers and 3/4 HP with auto feed metric and standard threading.

Like a lot of these machines it appears the POs neglected it, and probably didn't even know what an oil button was. I started dismantling it and I am stuck and cant go any further. That's not the end of the world though because I think I have made it far enough to clean bearings and the good stuff.

My question is, how do I clean and reoil, the gunk in the head stock gears and bearings had the consistency of wet brown sugar. I've found some inexpensive SAE 30 non detergent oil at walmart, the manual says SAE 20 non detergent so I figure it should be ok?

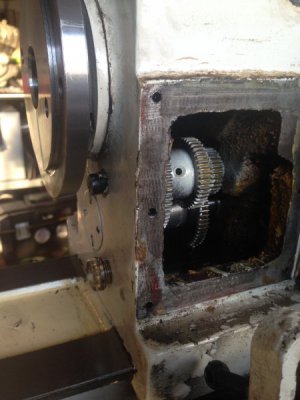

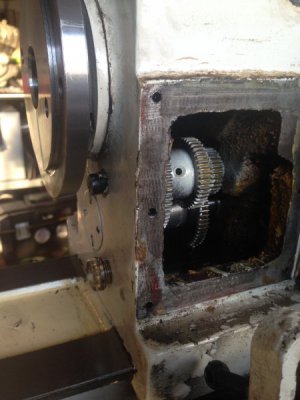

I've added some pictures below. It's just really gunky in there (someone used a heavy lubricant? grease?), luckily the lathe moved and sounded like it was brand new but when I switched over to the mill, it sounded pretty laboured. I've picked and scraped out a lot of the old sludge with little tools but there is still a lot in there. I cant seem to get it apart any further and I know there are two tapered roller bearings in there as well, what to do!?

Thank you!

Rob

Like a lot of these machines it appears the POs neglected it, and probably didn't even know what an oil button was. I started dismantling it and I am stuck and cant go any further. That's not the end of the world though because I think I have made it far enough to clean bearings and the good stuff.

My question is, how do I clean and reoil, the gunk in the head stock gears and bearings had the consistency of wet brown sugar. I've found some inexpensive SAE 30 non detergent oil at walmart, the manual says SAE 20 non detergent so I figure it should be ok?

I've added some pictures below. It's just really gunky in there (someone used a heavy lubricant? grease?), luckily the lathe moved and sounded like it was brand new but when I switched over to the mill, it sounded pretty laboured. I've picked and scraped out a lot of the old sludge with little tools but there is still a lot in there. I cant seem to get it apart any further and I know there are two tapered roller bearings in there as well, what to do!?

Thank you!

Rob