- Joined

- Jun 7, 2019

- Messages

- 478

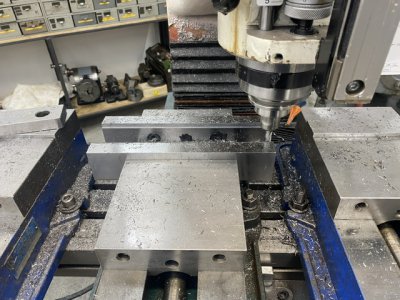

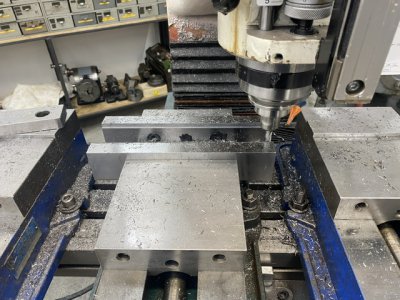

Needed a good way to hold 12”x1”x1.875” polypropylene for customer parts. Through drilled and pocketed near the ends so standard 6” step jaws would not provide enough support. So, new jaws were in order. I had a stick of 2x1 1018 steel. Used the TRAK mill to face and square 10” long pieces and pocket out the bolt holes. Surface ground flat and square matched together. milled the steps in place under clamping force. Then started in on the plastic parts. 79 parts all done. Made a big mess.