- Joined

- Jan 28, 2020

- Messages

- 197

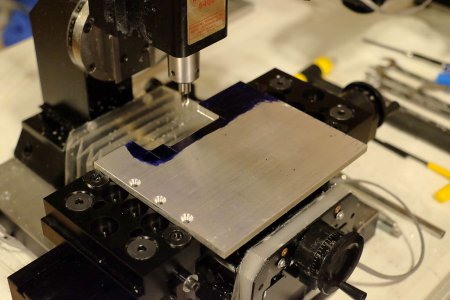

Sherline Products has a new product: MB Vise Fixture. It comes in two versions. The prices are 20% off this month (October 2021):

https://www.sherline.com/monthly-special/

Here is the product page:

https://www.sherline.com/product/35...Jaws&attribute_inserts=Reversible+Jaw+Inserts

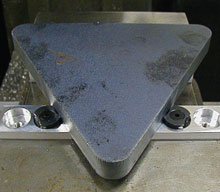

The vise fixtures hold stock on a mill table, using the t-slots. The cheaper version holds rectangular and square stock/parts only. The more expensive version also holds round stock/parts.

The "MB" stands for Mitee Bite.

Sherline has a instructional video on the vise fixtures, in two parts.

I didn't know of Mitee Bite vise fixtures before this new product introduction.

https://www.sherline.com/monthly-special/

Here is the product page:

https://www.sherline.com/product/35...Jaws&attribute_inserts=Reversible+Jaw+Inserts

The vise fixtures hold stock on a mill table, using the t-slots. The cheaper version holds rectangular and square stock/parts only. The more expensive version also holds round stock/parts.

The "MB" stands for Mitee Bite.

Sherline has a instructional video on the vise fixtures, in two parts.

I didn't know of Mitee Bite vise fixtures before this new product introduction.

Last edited: