- Joined

- Sep 6, 2020

- Messages

- 21

Well, the 728-VT finally arrived this last week. Thanks to all who chimed in on the decision thread > here. I ended up getting the mill, base, DRO install, Ultra Precision 0-.5" chuck, clamping kit and power x-axis feed. FYI...it's going to stay manual. No CNC for me. The packaged arrived without issue. Everything was packed very well. SAIA delivered and they rolled it right into the garage with no problems. Unloading the mill and getting onto the base by myself was a little challenging, but not as bad as I thought it would be. Setup was very straightforward with only a few hiccups. Here's what I ran into during the setup:

- Copper soft jaws for the vise

- Mini hold down fixture plate & clamps (Lipton style)

- T-nuts for a Vertex HV-6 rotary table

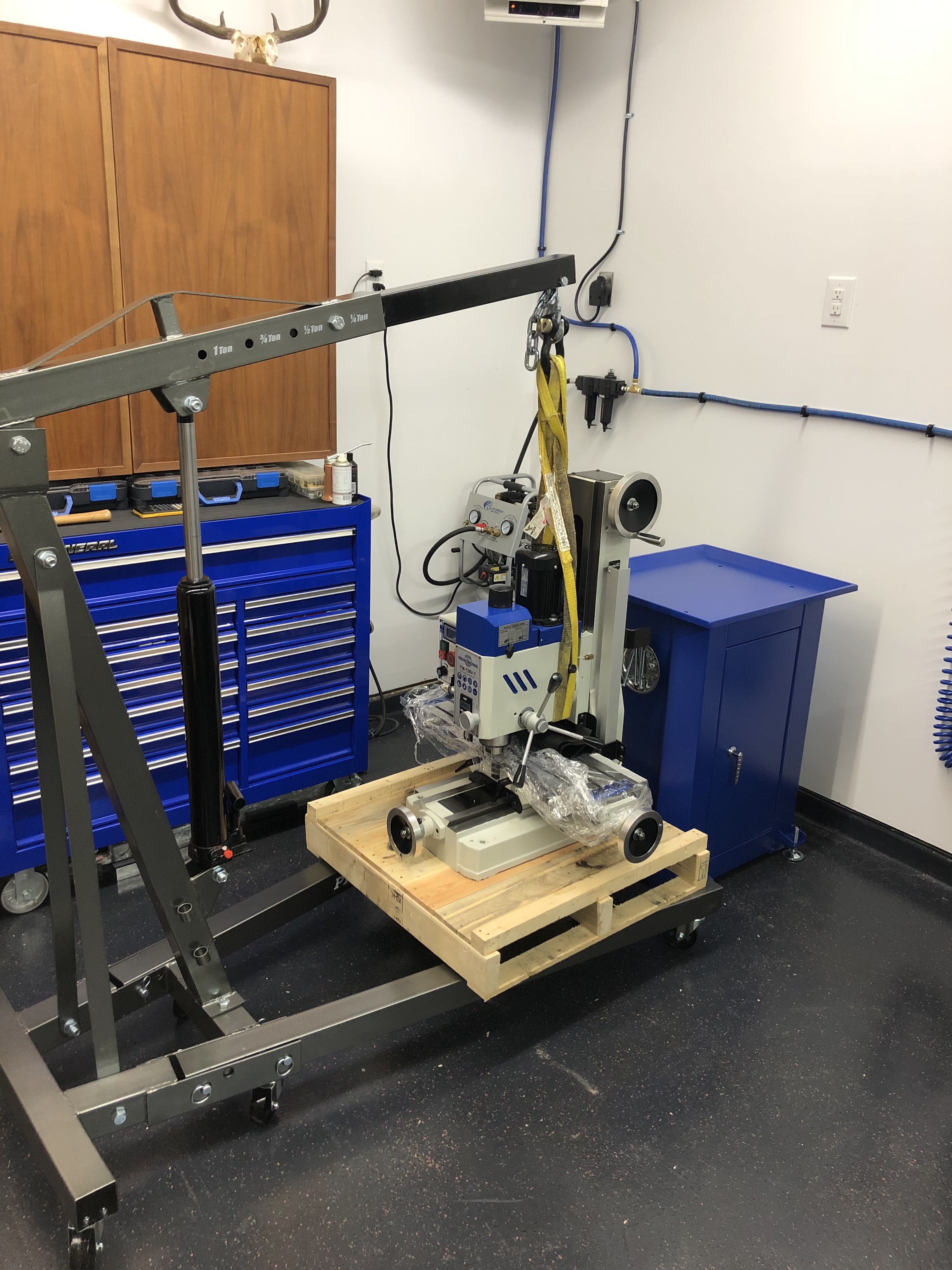

How the package arrived:

I used a 1-ton shop crane (HF) to lift it. It handled it fine.

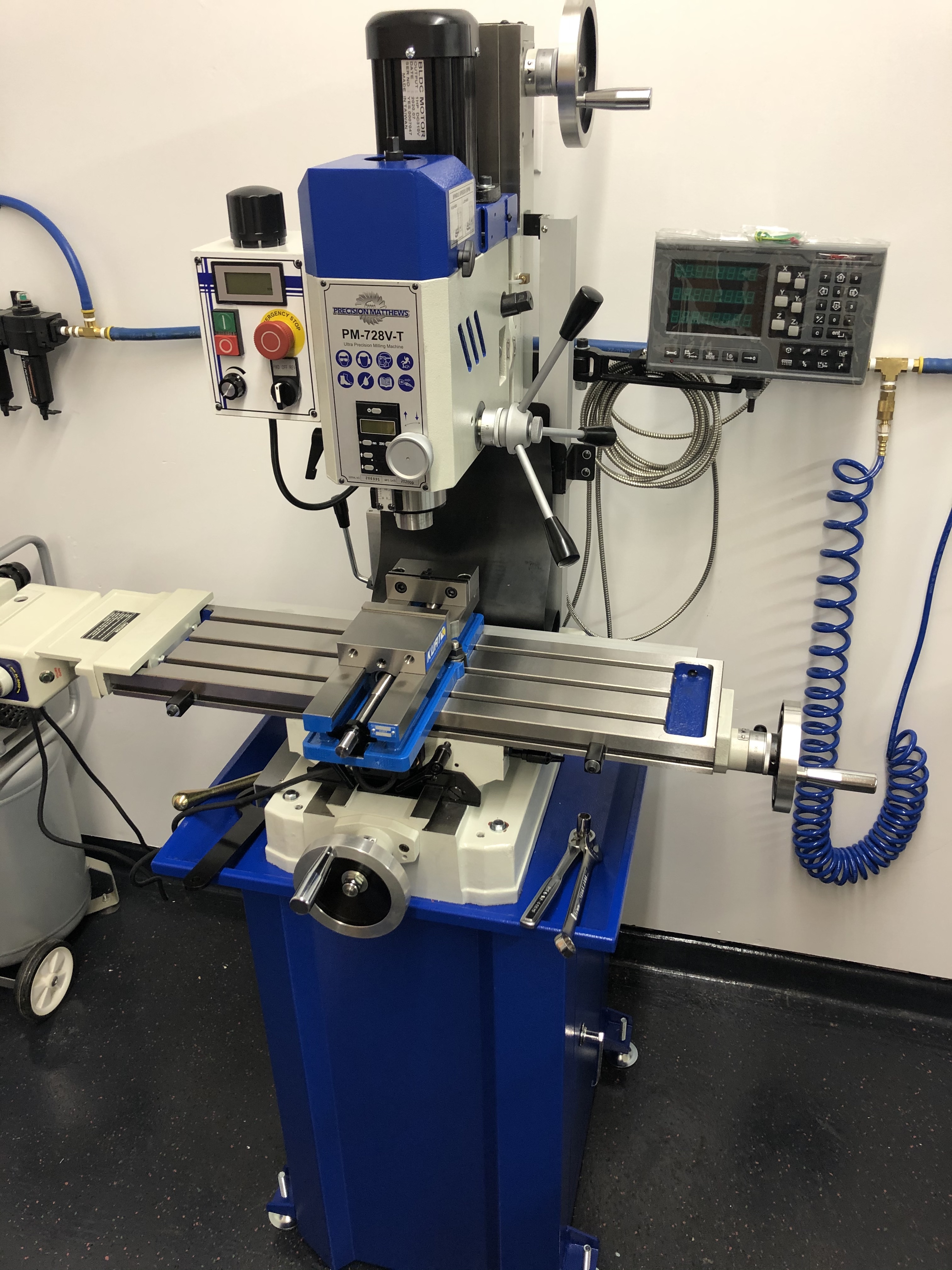

Fully Assembled:

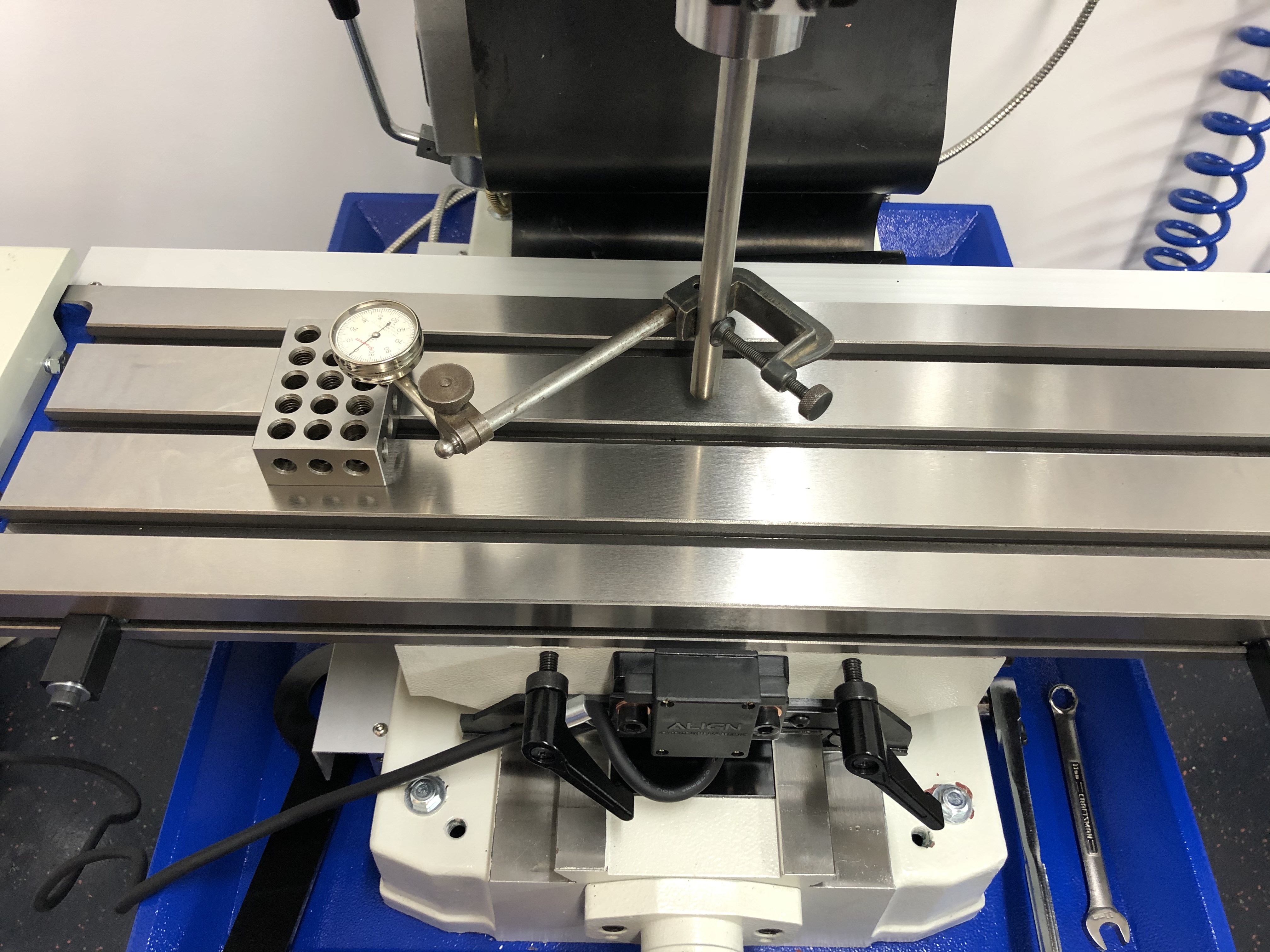

Tramming it in. I got the X-axis dead nuts very quickly with this setup. The Y-Axis has about .001" forward nod just with a quick check. I might mess with that later, but left it alone for now.

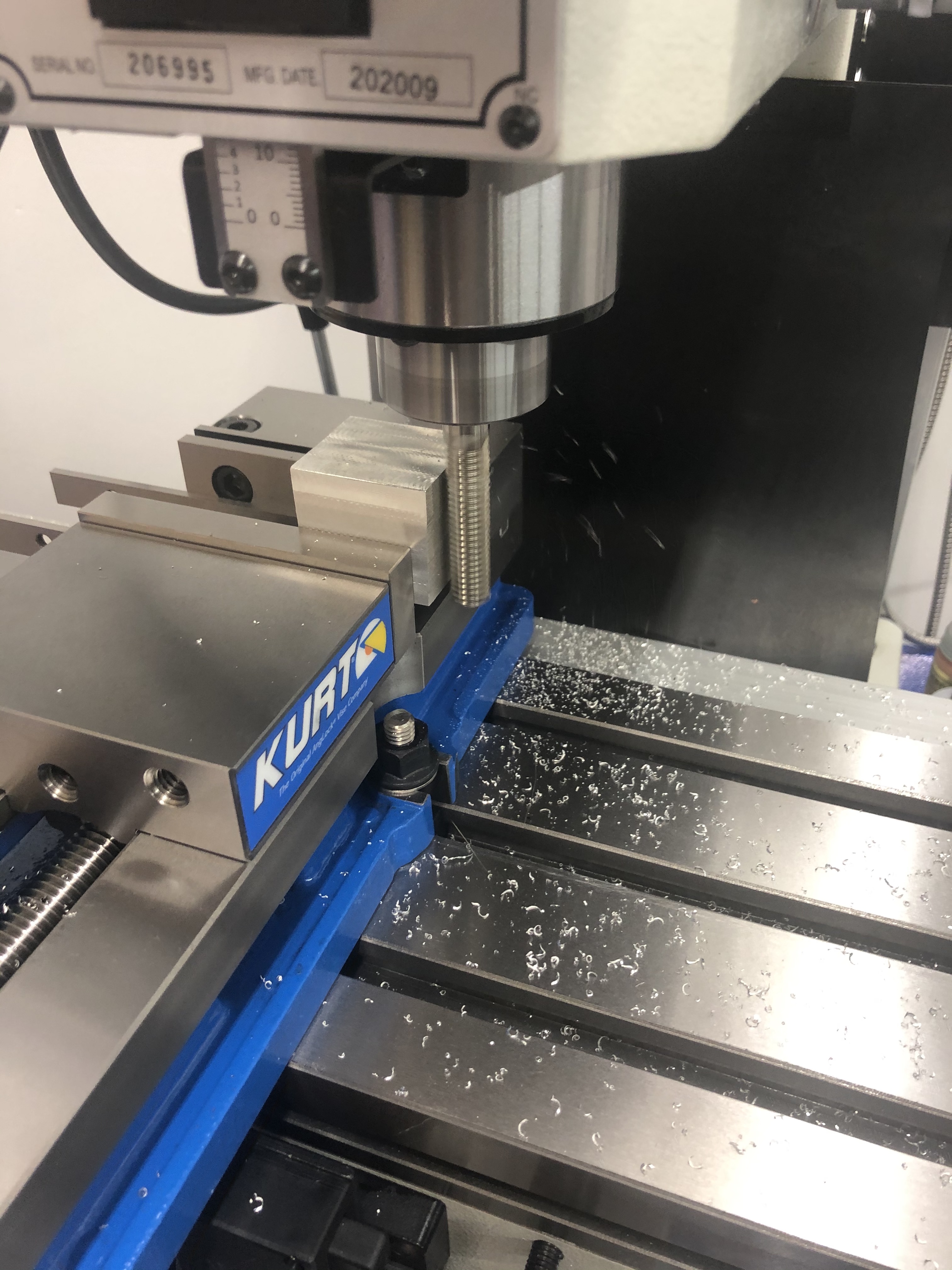

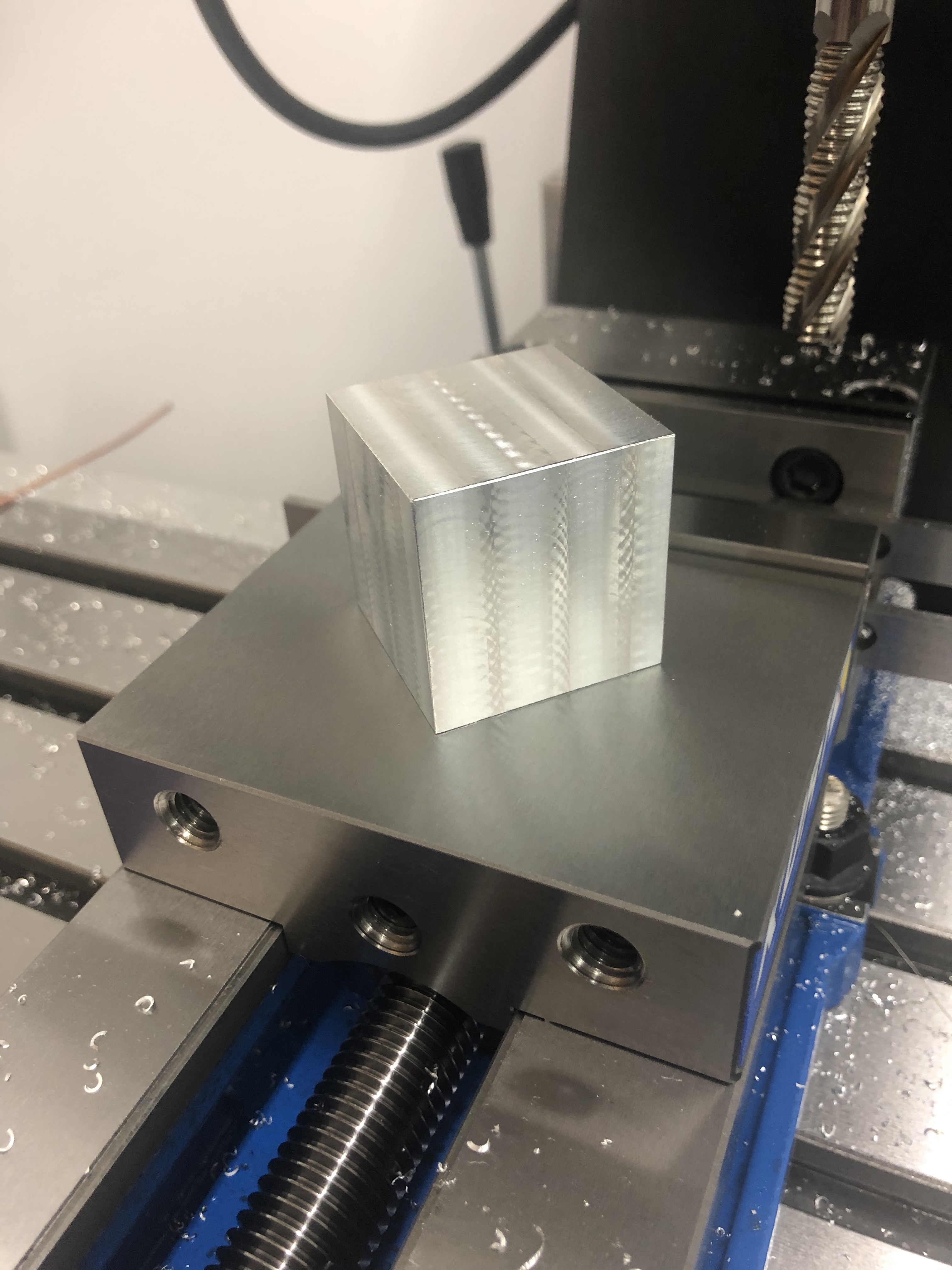

First chips: Using a roughing end mill, I went to town on a chunk of 6061. The mill makes pretty good blocks of metal so far from what I can tell.

Cheers!

- The bolts used to attach the power feed to the table were too short. I had to cut some 1.5" bolts down a little to fit within the table end tray and tighten up on the table edge.

- The thing didn't come with a manual.

Not a big deal cause you can get it online, but still.

- I checked the runout on the drill chuck and it was something like .0018" which is a higher than advertised, but only tried it once. I'll try again later to see if it was the setup.

- The DRO comes with a "grounding kit" (a 2' wire). Where am I supposed to hook the ground into? The instructions said nothing other than it was a "earth ground". Hooking that up to an actual earth ground is going to be a PITA. Is that necessary or can I just tie into the machine body somewhere? I have the DRO and the machine plugged into two separate panels.

- The quill has a noticeable "cog" to it when turned by hand and at very low speeds. I was anticipating it to free spin when the motor is off, but that's not the case. Feels like motor magnets are pulling on and off. It smooths out fine at high speeds. Maybe this is normal for this type of motor?

- Copper soft jaws for the vise

- Mini hold down fixture plate & clamps (Lipton style)

- T-nuts for a Vertex HV-6 rotary table

How the package arrived:

I used a 1-ton shop crane (HF) to lift it. It handled it fine.

Fully Assembled:

Tramming it in. I got the X-axis dead nuts very quickly with this setup. The Y-Axis has about .001" forward nod just with a quick check. I might mess with that later, but left it alone for now.

First chips: Using a roughing end mill, I went to town on a chunk of 6061. The mill makes pretty good blocks of metal so far from what I can tell.

Cheers!