- Joined

- Apr 23, 2011

- Messages

- 2,476

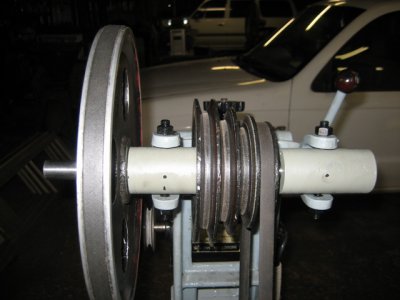

I have needed a new layshaft for sometime. At some stage in its life one of the factory original plain iron bearings had been replaced with a steel bushing, but still only running on the steel shaft. They had made provision for oiling but it always ran warm to hot.

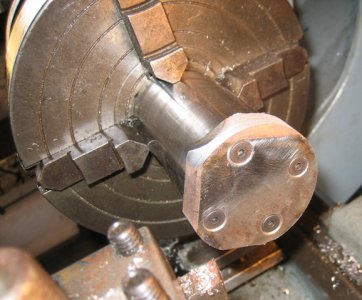

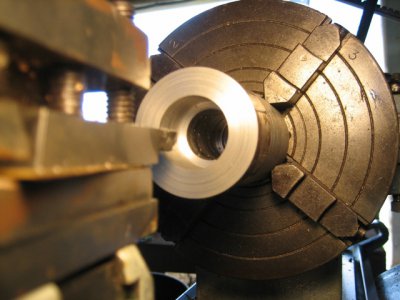

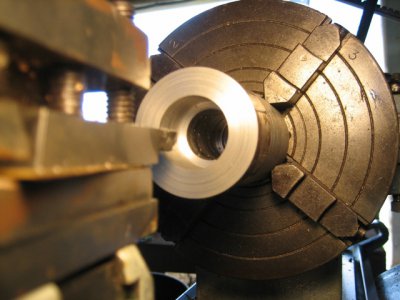

After replacing the drive motor and upping the RPM range, I thought it was time to fix the layshaft problem before something catastrophic occurred. So some 45mm dia 12L14 for bearing housings, various bits of flat bar from the scrap bin, needle rollers, oil seals and 4mm CS cap screws.

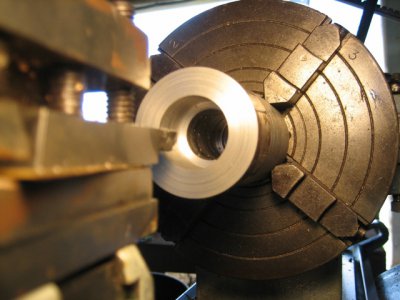

Cut the 12L14 to length, mounted up, drilled through 25/32”, then bore the recess for the needle rollers.

Cheers Phil

After replacing the drive motor and upping the RPM range, I thought it was time to fix the layshaft problem before something catastrophic occurred. So some 45mm dia 12L14 for bearing housings, various bits of flat bar from the scrap bin, needle rollers, oil seals and 4mm CS cap screws.

Cut the 12L14 to length, mounted up, drilled through 25/32”, then bore the recess for the needle rollers.

Cheers Phil