- Joined

- Nov 5, 2019

- Messages

- 233

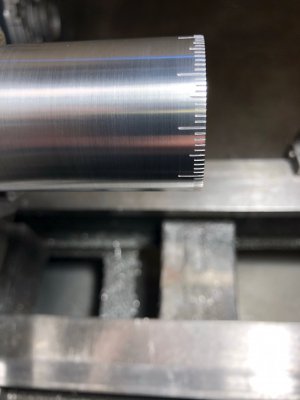

The dials on this lathe have annoyed me from day one, from the microscopic graduations to the set screw in the middle of the zero hash mark. You can buy new dials from Tallgrass tools but they're kind of pricey. I figured I have two hands and a lathe, I can make one. I watched a few videos and pretty much followed mrpetes plan of action.

I used a 100 tooth saw blade for the index and a 60 degree brazed carbide threading tool for the scribe. I have a heavy duty Starrett magnetic base that I used with half an old 6" scale for the pawl.

I made a jig like mrpetes for stamping the numbers. My number set is 1/8" and they are 5/16" square. After boring the hole for the dial, I cut a slot that was 7/16" wide centered on the hole. I then had to make (2) 1/16" shims and (1) 1/8" shim the length of the stamps. The zero gets a 1/16" shim on either side and the double numbers get the 1/8" shim on one side, then the other which gives you a nice distance between numbers. I made a practice dial because different numbers require different force to produce a good impression. Stamping flat numbers on a curved surface is an interesting process. I made all the parts on the lathe as I don't have a mill yet.

It was a lot of work making everything but it was worth it because you use the dials every time you use the lathe and my eyes probably won't be improving as I get older.

One other thing is there is no need for a fancy 3 position carriage stop for scribing the hash marks. I did all the tens, then the fives and then the ones. It's kind of a sanity check also. If you end up where you started you know the nothing has moved and you can move on to the next step. The dials are both 1/2" thick, 1.700 diameter. The inner dial has a 1" hole bored in it with a 6-32 set screw. The outer dial has 3/8" hole bored with a 8-32 counterbored hole for the knurled knob. The hash marks are .250 long for the tens, .150 for the fives and .100 for the ones.

I used a 100 tooth saw blade for the index and a 60 degree brazed carbide threading tool for the scribe. I have a heavy duty Starrett magnetic base that I used with half an old 6" scale for the pawl.

I made a jig like mrpetes for stamping the numbers. My number set is 1/8" and they are 5/16" square. After boring the hole for the dial, I cut a slot that was 7/16" wide centered on the hole. I then had to make (2) 1/16" shims and (1) 1/8" shim the length of the stamps. The zero gets a 1/16" shim on either side and the double numbers get the 1/8" shim on one side, then the other which gives you a nice distance between numbers. I made a practice dial because different numbers require different force to produce a good impression. Stamping flat numbers on a curved surface is an interesting process. I made all the parts on the lathe as I don't have a mill yet.

It was a lot of work making everything but it was worth it because you use the dials every time you use the lathe and my eyes probably won't be improving as I get older.

One other thing is there is no need for a fancy 3 position carriage stop for scribing the hash marks. I did all the tens, then the fives and then the ones. It's kind of a sanity check also. If you end up where you started you know the nothing has moved and you can move on to the next step. The dials are both 1/2" thick, 1.700 diameter. The inner dial has a 1" hole bored in it with a 6-32 set screw. The outer dial has 3/8" hole bored with a 8-32 counterbored hole for the knurled knob. The hash marks are .250 long for the tens, .150 for the fives and .100 for the ones.

Attachments

-

85CE7B80-B8FA-4172-BA78-D27080835562.jpeg392.6 KB · Views: 113

85CE7B80-B8FA-4172-BA78-D27080835562.jpeg392.6 KB · Views: 113 -

62BA2644-575E-42E2-87FB-5207045F9CD3.jpeg564.2 KB · Views: 87

62BA2644-575E-42E2-87FB-5207045F9CD3.jpeg564.2 KB · Views: 87 -

9DD9A8A9-6D97-483D-8A6D-2460AE2AA591.jpeg108.7 KB · Views: 95

9DD9A8A9-6D97-483D-8A6D-2460AE2AA591.jpeg108.7 KB · Views: 95 -

E59163D6-E50D-4E4A-9F96-35A162B4984E.jpeg64.9 KB · Views: 106

E59163D6-E50D-4E4A-9F96-35A162B4984E.jpeg64.9 KB · Views: 106 -

DC6DDE83-0B7D-42D0-8933-C47F119FE22F.jpeg644.8 KB · Views: 108

DC6DDE83-0B7D-42D0-8933-C47F119FE22F.jpeg644.8 KB · Views: 108