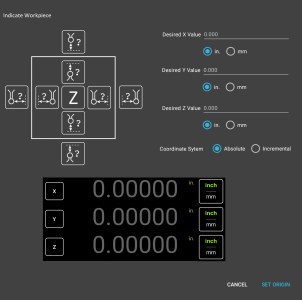

Ok, so... Spent some time in MSPaint, and cobbled together something I think would be a couple of good dialogs for indicating a workpiece, and selecting a tool.

I realize it's a bit... Busy. But I feel like this would be a more intuitive layout for probe direction/position.

Having the ability to probe the outside of one surface, and the inside of another along the same axis, would be super useful to locate a feature on a step.

Also, being able to specify desired values in each axis would be useful, if one is used to "working to zero".

Plus, I've often run into situations where having a real-time readout of position, while probing, would be helpful. For example, on a workpiece with a rounded end, it would be useful to find center in the Y axis, so that I knew that I was finding the true end of the part in the X axis.

I also cobbled together a "Tool Library" dialog, which I think would be accessed by a dedicated button on the function strip:

Having these two dialogs on the function strip, would be the proverbial "cat's ass".

Again, this is a good start to what **I** feel would be an intuitive UI for probing and the tool library. I welcome any and all constructive criticism (and, obviously, Yuriy has final say in the UI design, as this is well and truly his baby).

EDIT: Also, regarding the tool library, it would be useful to have a "drill bit" option, which would essentially set the tool diameter to Zero. Drilling a hole is typically reliant on the center of the hole, rather than the radius... I know that I could just clear the tool radius offset, but it would be faster and more intuitive to just be able to select the tool, and have the offset automatically returned to spindle center.