- Joined

- Feb 7, 2013

- Messages

- 792

I wanted a new lower longer cross slide but I did not want to spend much incase I did not like it. I got a piece of an old broken man hole cover cut a piece out and started machining it really cut pretty nice.

- - - Updated - - -

I lost some pictures on my camera but here is the cast iron part machined and dove tails cut and all hole drilled.

- - - Updated - - -

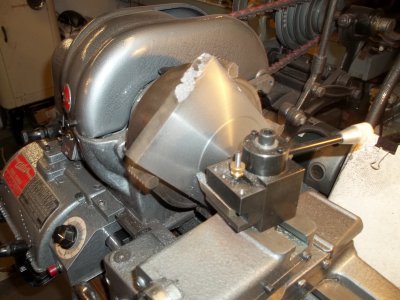

To cut the degrees I got out my old dragster degree wheel made a post at the rear of the lathe with a pointer and started cutting lines.

- - - Updated - - -

Here it is after the cuts but before the clean up.

- - - Updated - - -

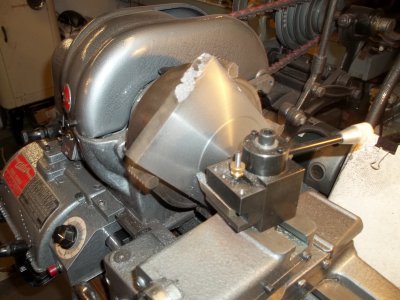

Here it is mounted four screws on top with one big counter sunk bolt on the othere side with epoxy inbetween.

- - - Updated - - -

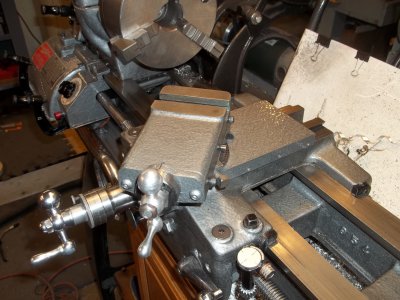

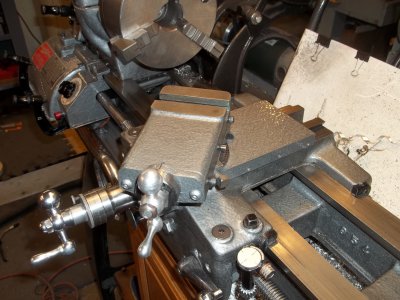

Here it is next to the stock one it is about three inches longer and it is a lot thicker I did not just mill out a bunch of clearance I kept things tight. I also made a longer brass nut it seems like a good idea..

- - - Updated - - -

Here it is without the gib I made that tonight out of yellow brass it dont look to bad it is also wider than the stock slide for weight and to make it stronger.

- - - Updated - - -

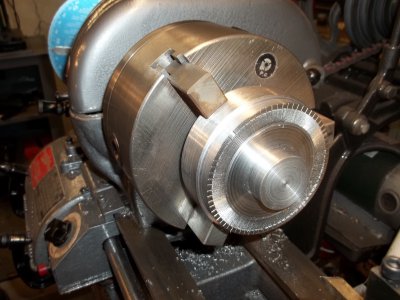

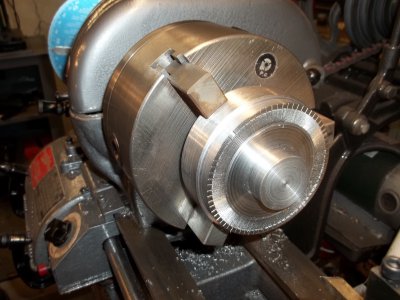

The numbers and lines are easy to read better than stock I dont have to stand on my head to see them I also numbered it all the way around.

- - - Updated - - -

Here it is all done works nice and smooth I will know better on a heavy cut. But the modification to the upper cross slide made a world of differance I am sure this will to. I will have to keep an eye open for more broken man hole covers. Thanks for lookin.. Ray