- Joined

- Nov 7, 2018

- Messages

- 186

The machine was ordered mid December of 2017 from ACRA Machinery. The machine took a few weeks to arrive from Taiwan and was shipped to the port of LA, then onto Ranch Cucamonga where ACRA is located. The machine was then delivered to my location via flatbed. The machine sustained a fair amount of paint damage due to poor handling on the truckers part. I ended up loading that machine and hauled it back some 500 miles back to ACRA for a different unit and returned the same day. I did end up getting a taper attachment for a decent discount for my troubles, but more importantly, the machine was handled with care and arrived unscathed. I had already posted about the saga in "members hangout" under "New machine arrives in used condition" so I won't double post.

I wanted to start a specific thread to document the modifications as well as review this machine to share with others who might find interest in the work performed and overall quality of this machine. I will end up posting some pictures found on the other thread, but they'e part of the inspection/review process and feel its important to include them.

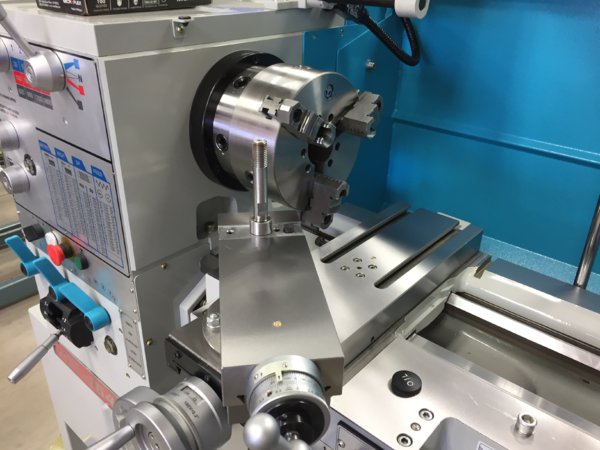

The machine was coated with with just enough comsoline to protect the exposed surfaces so clean up was fairly easy with minimal spirits. Once cleaned the quality fit and finish became apparent. The painted surfaces where equally impressive with no evidence of any overspray. The blue is a textured power coat finish.

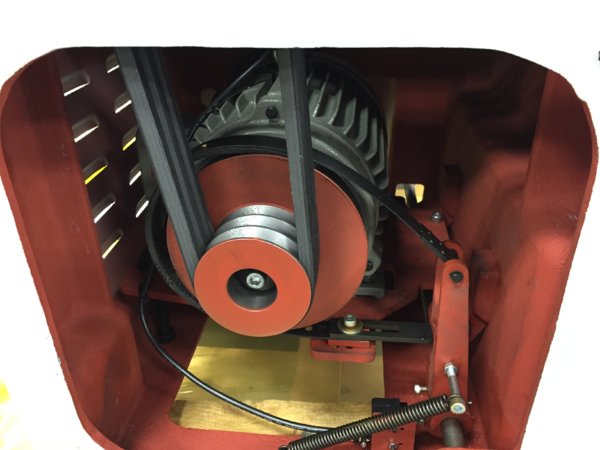

The motor is 5 hp that drives three belts. I was pleased how clean and smooth the inside casting is as well as the quality of motor. The belt tensioning system is also very nice. The foot brake bar linkage is well done and the friction brake is located on the motor.

Some detailed information:

FEATURES:

BED & STAND

One Piece Cast Iron Floor Stand With Foot Brake

Front Move Chip Tray Floor Stand Or Rear Chip Floor Stand Selected

Bed Width 10 1/4 " Bed Meehanite Casting, Vibration Stress Relieved

Induction hardened And Precision Ground Bed Ways

Precision Hand Scraped Removable Gap Bed

HEAD STOCK

Dynamic Balanced Spindle

Spindle Is Supported By 3 Points Precision Dearings-2 Taper Roller And 1 Ball Bearing

Housing Are Properly Stabilized And Deflection Free

All Gears And Shafts Are Made By Chromium Molybdenum Steel With Segmentation And Precision Ground

EVS Models Forced Lubrication System

Nylon Safety Gears In End Train

SPINDLE

Machined From Forged Alloy Steel, Hardened Ground & Dynamically Balance

Three Point Support By High Grade Precision Machine Tool Taper Roller & Ball Bearings

UNIVERSAL GEAR BOX

Induction Hardened And Ground Gears And Shafts

Wide Threads Cutting Capacity For Imperial, Metric, Module Pitch And Diametrical Pitch

APRON

Right Hand Side Or Left-Hand Size Apron. Hand-Wheel Available As Requested

Integrated Automatic Device For Longitudinal & Cross Feeds, Forward And Reverse Feeds

CARRIAGE & SLIDE

Anti-Float Design, Backlash Eliminator Fitted In Cross Slide Nut

Safety Clutches At Feed Shaft Lever

Dual Reading Dials

One Shut Lubrication For Carriage And Tops Slide

The Black collar on the spindle is a harmonic balancer with multiple tapped holes.The upper drive pulley is also balanced. The blue nylon gear is the safety gear mentioned in the previous features.

The end cover is made of fiberglass with two lower adjusting pins.

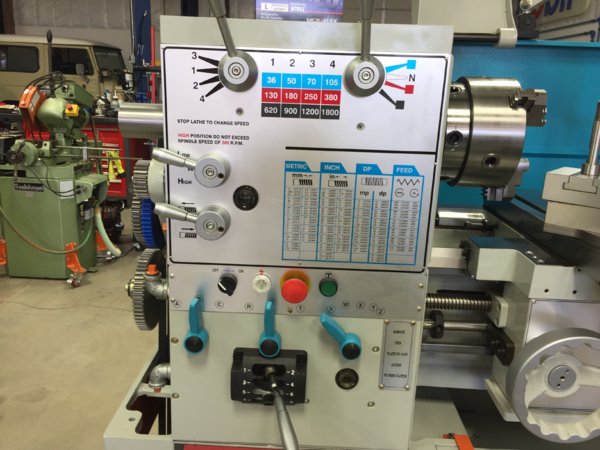

Very versatile selection of pitch/feed options.

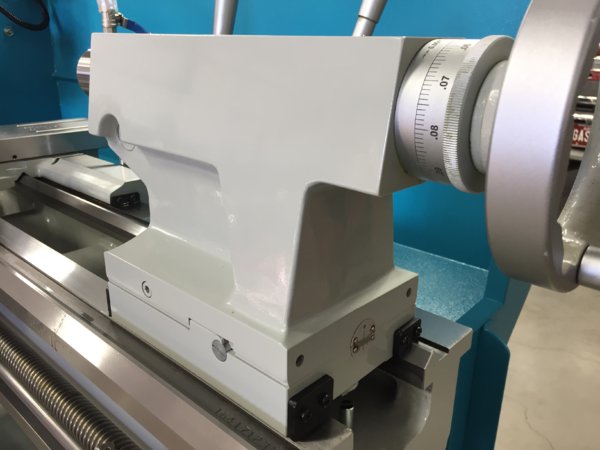

Carriage operates smooth with no notable backlash due to the anti-float design. The brass push knob is the one shot lubrication.

The lower push/pull round knob allows the operator to reverse direction on both carriage and cross slide on the fly.

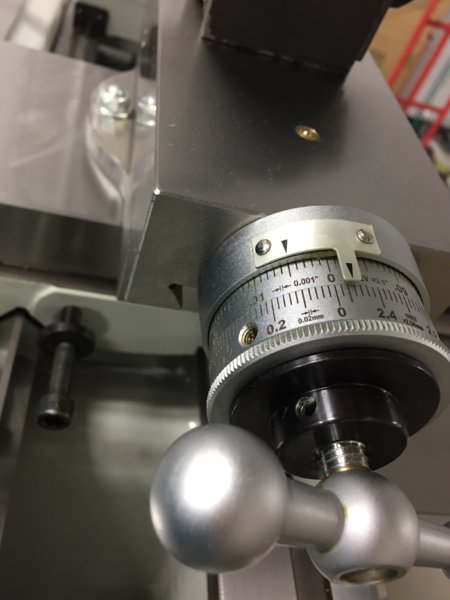

The dials are crisp and easy to read. The indexing collars rotates 180º to change viewing from metric to decimal.

Very nice fit and finish.

The lead screw measures 1.125" diameter. Feed rod, fwd/rev rod and lead screw share the same lubrication block.

The heavy cast aluminum end cover houses the FWD/REV switches.

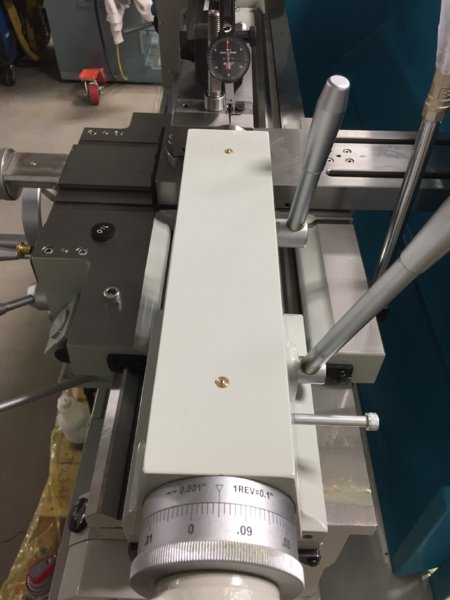

A shot of the bed.

The tail stock is a MT4 nice crisp dials.

The Meehenite bed measures 10.250" across with substantial webbing.

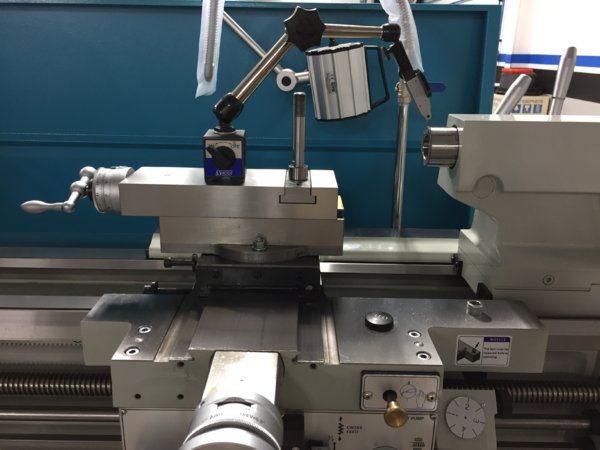

Now for some verifications on the the cross feed, compound, carriage and tailstock. I set up a magnetic test indicator to compare the dial graduations to actual movement. I was especially surprised with the carriage and tailstock results. The cross feed and compound where spot on but that should be expected.

The carriage was moved towards the head stock and both indicator and carriage dial zeroed.

The carriage was moved one tic mark (.010") and the test indicator reflected the exact number.

Next up was the compound verification. One tic= .001" Moved dial .005"

Good to go.

Cross feed. Had to turn off the overhead light due to glare but you can still make out the zeros.

.010" read .005 on test indicator.

The set up for the tailstock test. I re-checked the compound since it shared the same set up.

Set the tailstock dial to zero and zeroed the test indicator.

Again, the tailstock had surprising accuracy.

The second compound test using this set up. (.005")

Test indicator reading.

Uncrated the taper attachment and spent three hours cleaning and lubricating. I took it completely apart and reset the gibbs.

A very heavy unit and well made.

After reassembly and gibbs adjusted it floats smoothly back and forth. Used No.2 way oil.

OOPS! it seems I've exceeded the 30 photo limit per post.

To be continued....

Paco

I wanted to start a specific thread to document the modifications as well as review this machine to share with others who might find interest in the work performed and overall quality of this machine. I will end up posting some pictures found on the other thread, but they'e part of the inspection/review process and feel its important to include them.

The machine was coated with with just enough comsoline to protect the exposed surfaces so clean up was fairly easy with minimal spirits. Once cleaned the quality fit and finish became apparent. The painted surfaces where equally impressive with no evidence of any overspray. The blue is a textured power coat finish.

The motor is 5 hp that drives three belts. I was pleased how clean and smooth the inside casting is as well as the quality of motor. The belt tensioning system is also very nice. The foot brake bar linkage is well done and the friction brake is located on the motor.

Some detailed information:

FEATURES:

BED & STAND

One Piece Cast Iron Floor Stand With Foot Brake

Front Move Chip Tray Floor Stand Or Rear Chip Floor Stand Selected

Bed Width 10 1/4 " Bed Meehanite Casting, Vibration Stress Relieved

Induction hardened And Precision Ground Bed Ways

Precision Hand Scraped Removable Gap Bed

HEAD STOCK

Dynamic Balanced Spindle

Spindle Is Supported By 3 Points Precision Dearings-2 Taper Roller And 1 Ball Bearing

Housing Are Properly Stabilized And Deflection Free

All Gears And Shafts Are Made By Chromium Molybdenum Steel With Segmentation And Precision Ground

EVS Models Forced Lubrication System

Nylon Safety Gears In End Train

SPINDLE

Machined From Forged Alloy Steel, Hardened Ground & Dynamically Balance

Three Point Support By High Grade Precision Machine Tool Taper Roller & Ball Bearings

UNIVERSAL GEAR BOX

Induction Hardened And Ground Gears And Shafts

Wide Threads Cutting Capacity For Imperial, Metric, Module Pitch And Diametrical Pitch

APRON

Right Hand Side Or Left-Hand Size Apron. Hand-Wheel Available As Requested

Integrated Automatic Device For Longitudinal & Cross Feeds, Forward And Reverse Feeds

CARRIAGE & SLIDE

Anti-Float Design, Backlash Eliminator Fitted In Cross Slide Nut

Safety Clutches At Feed Shaft Lever

Dual Reading Dials

One Shut Lubrication For Carriage And Tops Slide

The Black collar on the spindle is a harmonic balancer with multiple tapped holes.The upper drive pulley is also balanced. The blue nylon gear is the safety gear mentioned in the previous features.

The end cover is made of fiberglass with two lower adjusting pins.

Very versatile selection of pitch/feed options.

Carriage operates smooth with no notable backlash due to the anti-float design. The brass push knob is the one shot lubrication.

The lower push/pull round knob allows the operator to reverse direction on both carriage and cross slide on the fly.

The dials are crisp and easy to read. The indexing collars rotates 180º to change viewing from metric to decimal.

Very nice fit and finish.

The lead screw measures 1.125" diameter. Feed rod, fwd/rev rod and lead screw share the same lubrication block.

The heavy cast aluminum end cover houses the FWD/REV switches.

A shot of the bed.

The tail stock is a MT4 nice crisp dials.

The Meehenite bed measures 10.250" across with substantial webbing.

Now for some verifications on the the cross feed, compound, carriage and tailstock. I set up a magnetic test indicator to compare the dial graduations to actual movement. I was especially surprised with the carriage and tailstock results. The cross feed and compound where spot on but that should be expected.

The carriage was moved towards the head stock and both indicator and carriage dial zeroed.

The carriage was moved one tic mark (.010") and the test indicator reflected the exact number.

Next up was the compound verification. One tic= .001" Moved dial .005"

Good to go.

Cross feed. Had to turn off the overhead light due to glare but you can still make out the zeros.

.010" read .005 on test indicator.

The set up for the tailstock test. I re-checked the compound since it shared the same set up.

Set the tailstock dial to zero and zeroed the test indicator.

Again, the tailstock had surprising accuracy.

The second compound test using this set up. (.005")

Test indicator reading.

Uncrated the taper attachment and spent three hours cleaning and lubricating. I took it completely apart and reset the gibbs.

A very heavy unit and well made.

After reassembly and gibbs adjusted it floats smoothly back and forth. Used No.2 way oil.

OOPS! it seems I've exceeded the 30 photo limit per post.

To be continued....

Paco

Last edited by a moderator: