- Joined

- Dec 27, 2019

- Messages

- 18

PM lathe users,

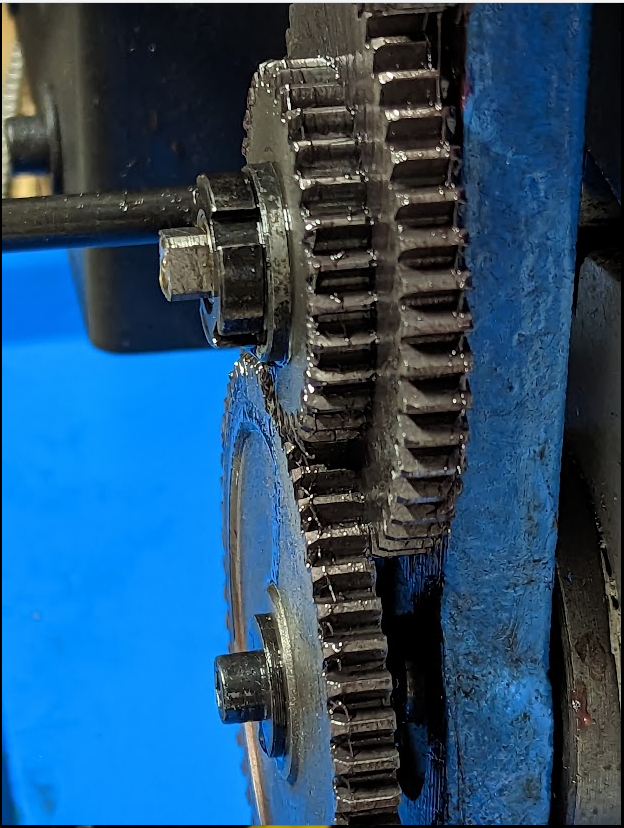

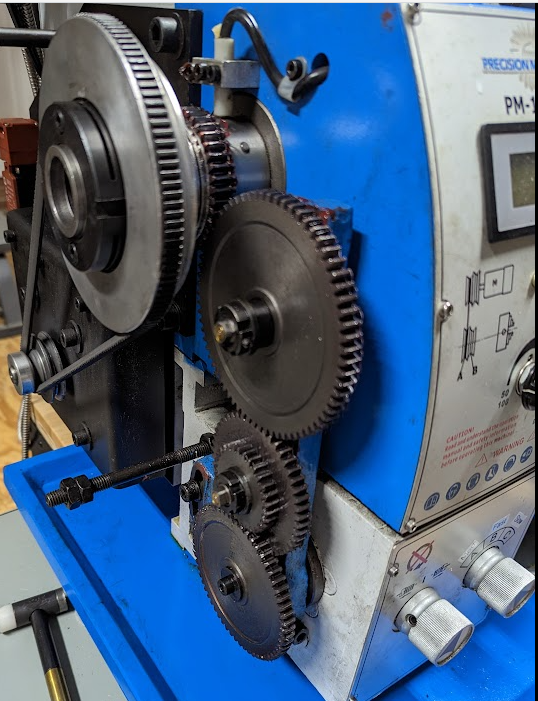

I have a PM1030V with the newer adjust-once change gear posts. Up until now, I had the default configuration shipped but today I decided to start single-point threading and needed to reconfigure the gear setup. Just in case it matters, I configured for 20TPI (inch) and noticed some issues. First, the "L" (bottom) gear was making contact with the side of its mating gear. The documentation is a bit sparse so I looked at the manual a few more times and it had a couple useful pictures and stated for the new gear pins that: The thick washer goes on the outside and the thin washer goes on the inside (next to the banjo). Apparently Chinese thin washers are not created equal because one was thicker than the other. I swapped the thicker "thin" washer on the bottom with the upper one and there was some clearance. Next, on the gear contact between the two adjustable gear stacks was slightly off so that one gear was overhanging a bit. I'm concerned about uneven gear wear. Before I start making a bunch of shim washers, etc. I'm hoping that someone has some good advice before I break something.

because one was thicker than the other. I swapped the thicker "thin" washer on the bottom with the upper one and there was some clearance. Next, on the gear contact between the two adjustable gear stacks was slightly off so that one gear was overhanging a bit. I'm concerned about uneven gear wear. Before I start making a bunch of shim washers, etc. I'm hoping that someone has some good advice before I break something.

Also, I use the piece-of-paper method for meshing the gears if that matters.

Thanks for your help!

I have a PM1030V with the newer adjust-once change gear posts. Up until now, I had the default configuration shipped but today I decided to start single-point threading and needed to reconfigure the gear setup. Just in case it matters, I configured for 20TPI (inch) and noticed some issues. First, the "L" (bottom) gear was making contact with the side of its mating gear. The documentation is a bit sparse so I looked at the manual a few more times and it had a couple useful pictures and stated for the new gear pins that: The thick washer goes on the outside and the thin washer goes on the inside (next to the banjo). Apparently Chinese thin washers are not created equal

Also, I use the piece-of-paper method for meshing the gears if that matters.

Thanks for your help!