No, this isn't another "I need a bigger shop" post...although it's true. The real estate I need is at the end of the workpiece. My work is in restoring vintage fountain pens, which involves a fair amount of parts fabrication; in fact, my Logan 820 was purchased for this purpose. Inappropriate as it may be in some ways for this use, I love it, have gotten it to work really well, and am now usually fabricating the parts I need in ebonite or acetyl and making specialty tools, usually in brass.

(First, a commercial: all of my HSS tools, which get the vast majority of playing time, are the result of Mikey's method and his patience as I learned how to grind and hone them.)

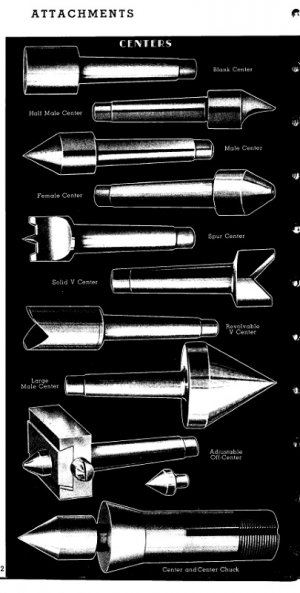

Much of what I'm turning has OD less than .300", OAL 1-2", and I'm generally working in a .002-.004 tolerance range. The issue I'm having is that getting access to the front of the workpiece is often a big challenge because it's skinnier than any center I have. In the picture you can see a center I made of 12L14 that is held in the tailstock, because the standard 2MT dead center is far too wide. I'm using the aloris extension tool holder, which helps a lot, but doesn't help me reach the end of the work. So often I will face and spot it right in at the chuck (I usually use the Beall chuck with ER32, as here; it's much easier for close in work like this), then move out as far as I need, but even 1-2" OAL is far too long to not have deflection when OD is only .200", as in this piece.

Is there something I'm missing here? Is there a rule about how far out of the tool holder I can push a tool, which also helps? Would making an even skinnier center work well or be too weak to prevent deflection?

When I'm turning ebonite, I use a tool made for the purpose and adjust its angle to face back to the tailstock, decreasing cutting forces on the soft stuff with really thin cuts. I can usually sneak the head of that tool, at a long angle, right in to the head of the work with a tiny bit of space to spare. More room to move would also be helpful there.

Thanks for the advice!

Tim

(First, a commercial: all of my HSS tools, which get the vast majority of playing time, are the result of Mikey's method and his patience as I learned how to grind and hone them.)

Much of what I'm turning has OD less than .300", OAL 1-2", and I'm generally working in a .002-.004 tolerance range. The issue I'm having is that getting access to the front of the workpiece is often a big challenge because it's skinnier than any center I have. In the picture you can see a center I made of 12L14 that is held in the tailstock, because the standard 2MT dead center is far too wide. I'm using the aloris extension tool holder, which helps a lot, but doesn't help me reach the end of the work. So often I will face and spot it right in at the chuck (I usually use the Beall chuck with ER32, as here; it's much easier for close in work like this), then move out as far as I need, but even 1-2" OAL is far too long to not have deflection when OD is only .200", as in this piece.

Is there something I'm missing here? Is there a rule about how far out of the tool holder I can push a tool, which also helps? Would making an even skinnier center work well or be too weak to prevent deflection?

When I'm turning ebonite, I use a tool made for the purpose and adjust its angle to face back to the tailstock, decreasing cutting forces on the soft stuff with really thin cuts. I can usually sneak the head of that tool, at a long angle, right in to the head of the work with a tiny bit of space to spare. More room to move would also be helpful there.

Thanks for the advice!

Tim

Last edited: