- Joined

- Dec 3, 2024

- Messages

- 8

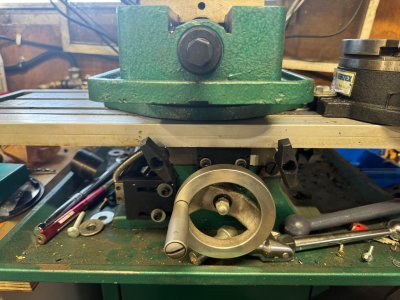

Good morning, guys! I have a G0704 mill and i love it, even if it is small and not a bridgeport (I got spoiled in college by having access to one, and until I have the space to get one, this guy will have to do).

I'm working on slowly upgrading it further with a power feed and power lift for the head, but I've run into a bit of a problem/conundrum. The previous owner fit the machine with a DRO (which is awesome), and when I began to look at installing the grizzly power feed, I discovered that the automatic stop box would need to mount in exactly the same spot as the DRO's x-axis sensor mounts. Further, the X-axis sensor for this DRO has replaced the ruler and slot system on the front of the table with a magnetic strip, so there's no slot to mount the auto-stop sensor blocks even if I wanted to.

Now, I realize that I could probably mount the power feed without mounting the auto-stop, and just be careful to pay attention when running the power feed so I don't do something crazy like crash the table into one end or the other, or worse.

However, I would like to use the auto-stop feature if possible. Given how it appears to work, it seems like it doesn't necessarily need to be centered on the machine as it shows in the instructions, so I suppose that I could mount a bracket of some sort to then mount the box to, and then mount the stop blocks to the metal shield that covers the DRO sensor, etc., but i'm not sure that's the best option.

So, I turn to you guys as experts. I would welcome any suggestions as to how to get both the power-feed and the DRO going without having to sacrifice either one.

Thanks!

I'm working on slowly upgrading it further with a power feed and power lift for the head, but I've run into a bit of a problem/conundrum. The previous owner fit the machine with a DRO (which is awesome), and when I began to look at installing the grizzly power feed, I discovered that the automatic stop box would need to mount in exactly the same spot as the DRO's x-axis sensor mounts. Further, the X-axis sensor for this DRO has replaced the ruler and slot system on the front of the table with a magnetic strip, so there's no slot to mount the auto-stop sensor blocks even if I wanted to.

Now, I realize that I could probably mount the power feed without mounting the auto-stop, and just be careful to pay attention when running the power feed so I don't do something crazy like crash the table into one end or the other, or worse.

However, I would like to use the auto-stop feature if possible. Given how it appears to work, it seems like it doesn't necessarily need to be centered on the machine as it shows in the instructions, so I suppose that I could mount a bracket of some sort to then mount the box to, and then mount the stop blocks to the metal shield that covers the DRO sensor, etc., but i'm not sure that's the best option.

So, I turn to you guys as experts. I would welcome any suggestions as to how to get both the power-feed and the DRO going without having to sacrifice either one.

Thanks!