- Joined

- Mar 20, 2014

- Messages

- 439

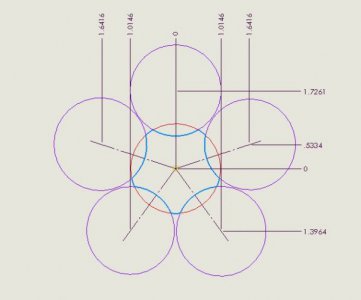

So, I decided to replace the travel lock knobs on my PM 932 mill. Well hey, I'm a hobby machinist right? Why would I buy 6 knobs at about 65 cents a piece, when I can buy a 10 dollar 1.75" dia aluminum round bar and spend countless hours making my own? What an easy project this will be! Or so I thought. I guess if I had cut the round bar into 6 chunks 1" thick, I could have then made the star shaped outside dia., and the center hole on each piece individually, ( doing it manually, as I don't have a rotary table) but that would have been a lot of setting up, and I'm too smart for that, right? I decided I would shape the OD of the whole 8" long round bar, and then cut it into the 6 knobs approx. 1" thick. Then I had the realization that I have no clue how to set it up or even how to shape the OD into something like the pic I've included. Something like this sure puts me in my place as a complete newbe (been on this for 2 days and have nothing to show). Would sure like to hear some opinions on this--If you say I can't do it that way, then how would you do it ??? Thanks, JR49

PS. Have lathe, mill, horiz. saw, drill press fair amount of tooling incl. a boring head and bars

PS. Have lathe, mill, horiz. saw, drill press fair amount of tooling incl. a boring head and bars