Robert,

To answer your question about the length of the bed of my lathe, the length of measured is 48"

Just a bit of my background, when I got out of tech school a few moons ago, my first job at the tool and die shop I worked for was cleaning the surface grinder tanks every Friday, so trust me I know what the meaning of swarf is. I thought I went to heaven when I was put on the Radial Arm Drill Press and the Moore Jig Boring machine after the tour of duty with rotten coolant and swarf tanks. Well the next 14 years worked up the food chain to finally getting assigned to the tool room, now that was Heaven, Hardinge Collet Lathes, Bridgeports with little or no backlash, Charmillles Wire EDM (love that machine) and a surface grinder room that was more like a surgical operating room, the coolest thing in the tool room was the huge black granite surface plate that looked more like a mirror. Made lots of cool prototype stuff, many items for the military and Polaris Industries.

But like all good things they do end, during the major economic down turn back in 2000 and 2001, more especially the economic uncertainty in Asia ,we lost a lot of contracts, business connections dried up and we laid off 50% of the plant 3 weeks before Thanksgiving of 2000, the killer to it all was when the tragedy of 9/11 occurred, it sealed the fate for the tool room and many of the tooling lines in the plant. 468 machinist lost our jobs 2 months after 9/11. The company is still in business, but it is a lot smaller today with maybe 1/3rd of the employees it had back in the late 90's

The good thing about the whole thing is, the company sent me back to school to re career in a different field as a part of our severance package, today I am a land surveyor, no more smelling like rotten coolant and tapmatic! ( the old good stuff with T1 in it)

I did enjoy machining, it was a great feeling to look at something you made, from a pile of steel or aluminum.

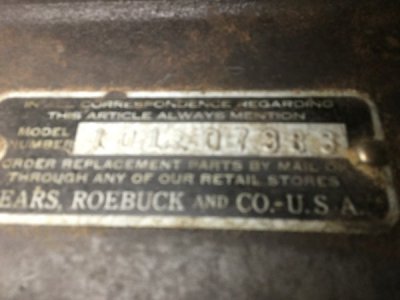

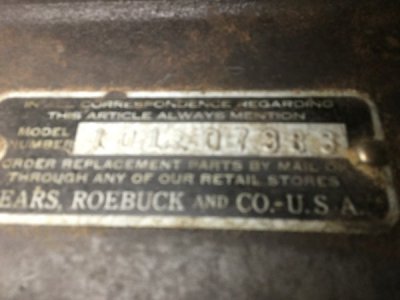

I am building a small machine shop for my own for my own use, as I collect antique gasoline engines and oil tractors. I know I could have bought a new import lathe with tighter precision, but where is the fun in that? Part of the addiction is the hunt for parts, the fellowship of others on the same quest and the satisfaction of knowing you saved a part of history, and of course cant forget the bragging rights!

Over the weekend I totally dismantled the lathe, cleaned every part, hand lapped the ways (yes I know the ways are not hardened), re polished all the gibbs and made a list of parts I need to get to make my lathe able to spit chips once again. It is a neat little machine, I really cant wait to turn my first raw casting on it, I am really looking forward to it.

It has been a while since I had my hands and head wrapped around a machine, but just like riding a bike, it is all coming back.

Kirbster