-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- SPECIFIC MANUFACTURERS OF MACHINE TOOLS

- BOXFORD, MYFORD, DENFORD VICEROY, EMCO & UNIMAT MACHINES

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Myford green paint

- Thread starter Subw00er

- Start date

- Joined

- Jan 2, 2019

- Messages

- 7,159

I'd take the gear cover off and look for a close match at the hardware store, acrylic enamel spray paint should hold up fine if you do good prep.

If you're trying to restore it for some kind of lathe concourse that might not be good enough, but if you just want to freshen it up not many people are judgemental about having the "correct" color on a machine tool. It's functionality that usually matters most.

Pictures are good too

Cheers,

John

(former British car restorer)

If you're trying to restore it for some kind of lathe concourse that might not be good enough, but if you just want to freshen it up not many people are judgemental about having the "correct" color on a machine tool. It's functionality that usually matters most.

Pictures are good too

Cheers,

John

(former British car restorer)

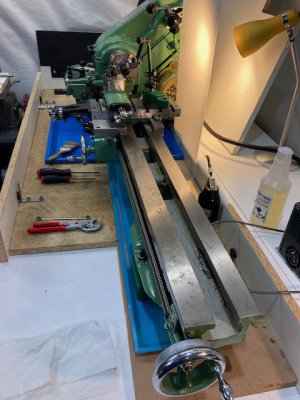

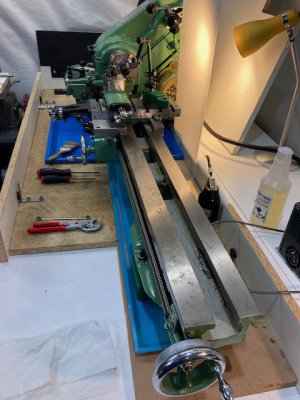

ok ill give that a shot Matt. Myford wont ship paint to the US. I am restoring this 'ol girl. Well not that old, early 80's. It turns out she's amazingly solid underneath. All of the ways and headstock bearing show scraping with no wear! Amazing. I've got her back to almost new looking state, minus some pitting here and there and paint chips. I just went ahead and ground the paint off the cover next to the gear box... most of it flaked right off so I had to do something. It actually doesn't look bad as bare metal. I do have an motor shield to paint though.

Attachments

Last edited:

Here are some current pics. She shined up pretty nice. Check out the main bearing crosshatching still present and runout! I dont think this unit was ever really used. I made a little custom controller for it too (connected to a Baldor 1hp and L.510 Teco VFD). So cute with its mini levers (direction and jogging).  I am in the process of adding a RPM gauge to the little controller box but the one I received was defective.

I am in the process of adding a RPM gauge to the little controller box but the one I received was defective.

View attachment runout.MOV

I haven't made a lot of chips yet, but it does make a really nice cut so far. Very smooth when the speed and feed is correct, which in my case, is of near infinite permutations! I make a lot of rings and parts for my motorcycle, and a little bit for work. I'll share some stuff later on.

One thing I noticed was really cool is that you can activate the power feed and power cross slide at the same time and make a perfect 45deg chamfer cut, either positive or negative. How cool would it be to have a lever dynamically controlling the rate and direction of the power cross slide? That invention may be in my future to create some more organic shapes.

The other thing that surprised me was the amount of oil this thing poops out. Its a messy girl! I'm going to have to mitigate some of that. The more astute of you will notice my little shop has carpets... and, oh, I machine barefoot. Don't judge. I'm the safety officer at my work so I totally know what TO DO, and when home, I prefer to take as much risk as possible. I kinda feel like it settles the score, yunno. Why, just tonight I dropped a folding chair on my bare foot, and I'm pretty sure its either really sprained or, well, partially broken.

I'm going to have to mitigate some of that. The more astute of you will notice my little shop has carpets... and, oh, I machine barefoot. Don't judge. I'm the safety officer at my work so I totally know what TO DO, and when home, I prefer to take as much risk as possible. I kinda feel like it settles the score, yunno. Why, just tonight I dropped a folding chair on my bare foot, and I'm pretty sure its either really sprained or, well, partially broken.

View attachment runout.MOV

I haven't made a lot of chips yet, but it does make a really nice cut so far. Very smooth when the speed and feed is correct, which in my case, is of near infinite permutations! I make a lot of rings and parts for my motorcycle, and a little bit for work. I'll share some stuff later on.

One thing I noticed was really cool is that you can activate the power feed and power cross slide at the same time and make a perfect 45deg chamfer cut, either positive or negative. How cool would it be to have a lever dynamically controlling the rate and direction of the power cross slide? That invention may be in my future to create some more organic shapes.

The other thing that surprised me was the amount of oil this thing poops out. Its a messy girl!

Last edited:

No, no I dont want all the computer wizbangery, I just want a proportional lever to control the cross slide. I'm not sure what motor controller would work for that, maybe something from Pololu, or if levers like this exist (maybe a pot makes more sense), but a gear reduce motor would be fairly easy to stick on the back side of the cross slide, right?

- Joined

- Jan 2, 2019

- Messages

- 7,159

Depending on the type of work you envision gravers might be what you're looking for.

www.hobby-machinist.com

www.hobby-machinist.com

John

Gravers for turning

In another thread, Brino asked some questions about gravers that we'll take up here: @mikey[/USER], that sounds like it's worth it's own thread. Maybe you could answer some questions; are you referring to brass projects only? if not, what materials do you work free-hand? are they HSS tools...

www.hobby-machinist.com

www.hobby-machinist.com

John

Hmm, tempting, but a bit to scary to hand hold a tool which is turning metal. I think that might be in the unacceptable level of risk category for me.

With that said, I have hand held razor blades to shape brass corners before and well, it works awesome. I'm not doing that anymore though, too scary. I just picked up an old grinder with the lathe, so I can make my own corners. After I refurb it too.

I'm not doing that anymore though, too scary. I just picked up an old grinder with the lathe, so I can make my own corners. After I refurb it too.

With that said, I have hand held razor blades to shape brass corners before and well, it works awesome.