- Joined

- Jan 22, 2012

- Messages

- 655

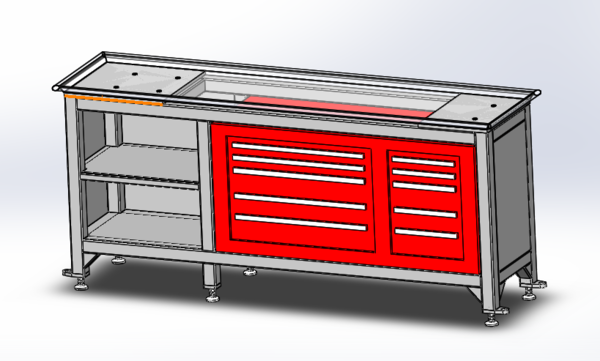

Back when I first got my PM1340GT lathe I had some issues with the factory stand. The mounting plates were a little too flexible allowing some vibrations to magnify causing the lathe to shimmy. I also wished there was more usable storage than the factory stand provided. At that point I decided to build my own stand that would address both issues.

I designed the stand around a Harbor Freight 44" top box as it was a good height and width and I already have the bottom box and am impressed with the quality. I chose to remove the lid and trim the flange so the box would have a close fit and look "built in".

The main tubes are 2" square, I used .125" wall but thicker wall tubing would add more mass. Either works fine. I also used some 1" sq tubing and angle for mounts. The skin is 12 gage and I did mine flush so I could blend the welds and finish them for paint. I wanted a "one piece" look, it ended up adding a lot of labor but looks cool. The two mount plates that the lathe bolts to are .500" P&O that are laser cut to ensure best flatness. The first 2 I got were sheared, they looked like a potato chip, so I tried laser cut and they were very flat.

The idea with this design is to create as flat a mounting surface as possible considering it will be as welded and not machined. To reduce warp due to welding the main frame is fully tacked up before welding. The two mount plates aren't mounted until all of the other welding is completed. I used tubing to align the 2 mount plates and then did several 1" welds to secure them. I added 2x2 angle to support the tool box and added a shelf.

I setup the ends first, then added in the long sections making sure it was as square as I could make it.

I metal finished and smoothed the joints with body filler to get the smooth, seamless look and then finished up with a single stage urethane paint job.

Here it is with the lathe mounted.

Member bss1 has some very nice additions that he did on his version, please check it out.

http://www.hobby-machinist.com/threads/another-pm1340gt-build.52267/

I've attached prints for the major components and a cut list for the tubing.

I designed the stand around a Harbor Freight 44" top box as it was a good height and width and I already have the bottom box and am impressed with the quality. I chose to remove the lid and trim the flange so the box would have a close fit and look "built in".

The main tubes are 2" square, I used .125" wall but thicker wall tubing would add more mass. Either works fine. I also used some 1" sq tubing and angle for mounts. The skin is 12 gage and I did mine flush so I could blend the welds and finish them for paint. I wanted a "one piece" look, it ended up adding a lot of labor but looks cool. The two mount plates that the lathe bolts to are .500" P&O that are laser cut to ensure best flatness. The first 2 I got were sheared, they looked like a potato chip, so I tried laser cut and they were very flat.

The idea with this design is to create as flat a mounting surface as possible considering it will be as welded and not machined. To reduce warp due to welding the main frame is fully tacked up before welding. The two mount plates aren't mounted until all of the other welding is completed. I used tubing to align the 2 mount plates and then did several 1" welds to secure them. I added 2x2 angle to support the tool box and added a shelf.

I setup the ends first, then added in the long sections making sure it was as square as I could make it.

I metal finished and smoothed the joints with body filler to get the smooth, seamless look and then finished up with a single stage urethane paint job.

Here it is with the lathe mounted.

Member bss1 has some very nice additions that he did on his version, please check it out.

http://www.hobby-machinist.com/threads/another-pm1340gt-build.52267/

I've attached prints for the major components and a cut list for the tubing.

Attachments

-

mnt plate lh upper.PDF46.6 KB · Views: 267

-

mnt plate rh upper.PDF45.9 KB · Views: 242

-

PM1340GT lathe stand detail.PDF53.9 KB · Views: 284

-

PM1340GT lathe stand.PDF74.1 KB · Views: 255

-

PM1340GT lathe stand2.PDF74.5 KB · Views: 239

-

SHELF1.PDF43.5 KB · Views: 194

-

skin1.PDF42.6 KB · Views: 195

-

skin2.PDF42.5 KB · Views: 187

-

threaded pad.PDF45.6 KB · Views: 224

-

PM1340GT lathe stand cut list.doc23.5 KB · Views: 289

. Thanks for posting them here as they are a great asset to anyone wanting to build their own stand for the 1340 GT.

. Thanks for posting them here as they are a great asset to anyone wanting to build their own stand for the 1340 GT.