- Joined

- Aug 5, 2013

- Messages

- 281

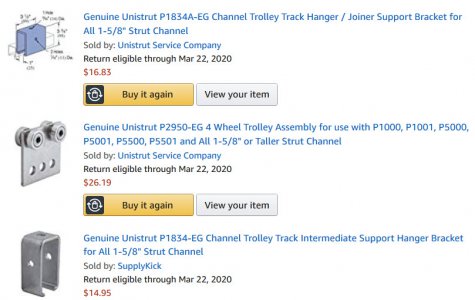

I installed a section of Unistrut with a wheel trolley, for removing, installing storing my heavy lathe chucks

I can easily remove/install a heavy chuck with this setup and roll it over to a cart which stores my chucks.

I can move the cart, or leave it where it is.

Prior to this I was using A Sky Hook hoist, which was cumbersome.

This works quite well. I have to redo the part which attaches to the chuck

Dan

I can easily remove/install a heavy chuck with this setup and roll it over to a cart which stores my chucks.

I can move the cart, or leave it where it is.

Prior to this I was using A Sky Hook hoist, which was cumbersome.

This works quite well. I have to redo the part which attaches to the chuck

Dan