-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My PM-728VT

- Thread starter xyz

- Start date

- Joined

- Jul 22, 2020

- Messages

- 30

Can you please confirm the width of the delivery pallet? PM's website says it's 34" wide. My door is 34.5" so any wider and it won't fit uncrated. Thank you!I started to uncrate the PM-728VT crate today.

Some people have posted videos on how to use an engine hoist to raise the mill onto the table. I am thinking of doing it that way, too.

I'll measure and let you know tomorrow, if you can wait until then. It was TOO large for the Harbor Freight 2 and half ton engine hoist. I ended up using a home made gantry with an electric winch.Can you please confirm the width of the delivery pallet? PM's website says it's 34" wide. My door is 34.5" so any wider and it won't fit uncrated. Thank you!

- Joined

- Jul 22, 2020

- Messages

- 30

Thanks. Tomorrow is fine. And when you say it was too large for the harbor freight hoist do you mean the pallet was too wide for its legs to straddle it? I was planning to use a similar lift.

I spent the day building a small pallet that just matches my Harbor Freight pallet jack. Someone on the internet suggested it. Here is a picture of the 728VT sitting on the pallet. It's not too large, not too small, just right.

The pallet is composed of three layers of wood.

The bottom layer is composed of two 1x2 boards. Spar varnish was not applied to them: They touch the garage floor and are sacrificial. They hold together the four 2x4's that run parallel with the tines of the pallet jack.

The middle layer is composed of four 2x4's. Two are outside of the pallet jack; two are inside the tines. They are coated with spar varnish.

The deck is made of 2x6's and one 2x8 which was ripped so that there is no space or crack in the platform. The levelling pads sit center on the front and rear 2x?. It's spar varnished in anticipation of coolant and oil spills.

All boards were put through a jointer to make a reference surface; then the long edges were put through the jointer to get square sides. Similar pieces of the boards were put through a planer to get like thicknesses. All surfaces don't get glue, but the glue surfaces are fresh wood because of the jointer and the planer. The pallet was glued and kept rigid while the glue set with brad nails. Planing and sanding was done to flatten the inevitable unevenness of the joints before applying the spar varnish.

The gantry and power winch were used to transfer the mill from the large delivery pallet to the just made one.

Today was wook working, all though it was for a metal mill. Maybe power and chips tomorrow.

The pallet is composed of three layers of wood.

The bottom layer is composed of two 1x2 boards. Spar varnish was not applied to them: They touch the garage floor and are sacrificial. They hold together the four 2x4's that run parallel with the tines of the pallet jack.

The middle layer is composed of four 2x4's. Two are outside of the pallet jack; two are inside the tines. They are coated with spar varnish.

The deck is made of 2x6's and one 2x8 which was ripped so that there is no space or crack in the platform. The levelling pads sit center on the front and rear 2x?. It's spar varnished in anticipation of coolant and oil spills.

All boards were put through a jointer to make a reference surface; then the long edges were put through the jointer to get square sides. Similar pieces of the boards were put through a planer to get like thicknesses. All surfaces don't get glue, but the glue surfaces are fresh wood because of the jointer and the planer. The pallet was glued and kept rigid while the glue set with brad nails. Planing and sanding was done to flatten the inevitable unevenness of the joints before applying the spar varnish.

The gantry and power winch were used to transfer the mill from the large delivery pallet to the just made one.

Today was wook working, all though it was for a metal mill. Maybe power and chips tomorrow.

Attachments

The pallet was too wide and long. I tried to raise the hoist, but when it looked dangerous, I switched to the gantry, less dangerous but still dangerous. The machine just barely fits between the legs. I couldn't see how not to ding it because lifting it cause it to tilt.Thanks. Tomorrow is fine. And when you say it was too large for the harbor freight hoist do you mean the pallet was too wide for its legs to straddle it? I was planning to use a similar lift.

The gantry is nothing more than two HF 'under hoists' on a triangular platform on wheels. There is a two-2x4 that I use when its about 500 pounds or less that has to be lifted. I use multiple 2x6 and or 2x8's depending on the load. I am telling you what I did, not suggesting what you might do. Lifting is inherently a dangerous chore and caution is advise.

Here is a picture just before I abandoned the use of the engine hoist. I'll get you the measurements tomorrow. The shop is 2 miles away.Thanks. Tomorrow is fine. And when you say it was too large for the harbor freight hoist do you mean the pallet was too wide for its legs to straddle it? I was planning to use a similar lift.

Maybe they used the larger (lower pallet) because ....

The smaller pallet upon which the machine directly sits is non standard form. I couldn't get my pallet jack into it, EVEN if I could get it off the larger pallet.

I'm just noting, not complaining. My buddy thinks I am having too much fun solving problems. So far, it's all been solvable, and most importantly, there have been no damage to the machines.

At the right edge of this picture, foreground to the ladder, and behind the handle of the pallet jack, a portion of the under hoist is shown on its 3-legged platform which is on rollers. It's one half of what I call my home made gantry.

thanksMy goto sealing compound in the shop is 3M 5200 Fast Cure Marine

But what to seal !

You asked for measurements. They are below.The pallet was too wide and long. I tried to raise the hoist, but when it looked dangerous, I switched to the gantry, less dangerous but still dangerous. The machine just barely fits between the legs. I couldn't see how not to ding it because lifting it cause it to tilt.

The gantry is nothing more than two HF 'under hoists' on a triangular platform on wheels. There is a two-2x4 that I use when its about 500 pounds or less that has to be lifted. I use multiple 2x6 and or 2x8's depending on the load. I am telling you what I did, not suggesting what you might do. Lifting is inherently a dangerous chore and caution is advise.

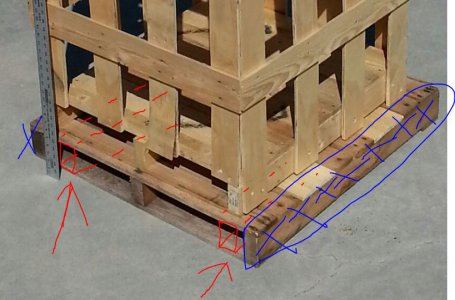

I had not broken down the crating nor the pallets, yet. So you can see how it was delivered to me. I lifted the cage off the pallet to expose the mill. My situation may be special, because the 748VT was delivered with the TL-1640 (PM-1640TL) and a saw, in three crates, on a flat bed with a fork lift.

The three images show how it was delivered; the small pallet (the machine is bolted down at 45 deg as shown by the black marks, be careful of the handles) on top of the large pallet; and the large pallet by itself.

The "yard stick" is 48 inches long.

The two pallets together are 10 1/2 inches tall. The Harbor Feight 2 1/2 ton pallet jack fits into the lower pallet. The bottom pallet is, in inches, 4 5/8 x 33 3/4, x 28 3/4.

Below is a picture of the smaller pallet by itself. It is, in inches, 5 1/2 x 28 x 28 3/4. Notice that the pallet cannot be used for this pallet. Notice the black marks on the small pallet. They look like two square brackets facing each other. Those are the marks left by the mill. And if you look carefully, you can see the four bolt holes near the corners of the brackets.

Hope your delivery is like others that I have seen on the internet.

- Joined

- Jul 22, 2020

- Messages

- 30

Thank you so much! Hugely helpful. Most importantly I do see the larger "bottom" pallet is in fact just shy of 34" wide. Also extremely helpful to see these pics and I now know that getting the mill off the upper pallet and onto the stand will require more than a standard 2.5 ton engine hoist. That's what I had planned to use. Maybe I could add additional supports inside the lower pallet and then trim it to match the width of the upper pallet? Or is even that smaller pallet too wide for the standard hoist? Pic attached. Again...many thanks!You asked for measurements. They are below.

I had not broken down the crating nor the pallets, yet. So you can see how it was delivered to me. I lifted the cage off the pallet to expose the mill. My situation may be special, because the 748VT was delivered with the TL-1640 (PM-1640TL) and a saw, in three crates, on a flat bed with a fork lift.

The three images show how it was delivered; the small pallet (the machine is bolted down at 45 deg as shown by the black marks, be careful of the handles) on top of the large pallet; and the large pallet by itself.

View attachment 377523

The "yard stick" is 48 inches long.

View attachment 377524

The two pallets together are 10 1/2 inches tall. The Harbor Feight 2 1/2 ton pallet jack fits into the lower pallet. The bottom pallet is, in inches, 4 5/8 x 33 3/4, x 28 3/4.

Below is a picture of the smaller pallet by itself. It is, in inches, 5 1/2 x 28 x 28 3/4. Notice that the pallet cannot be used for this pallet. Notice the black marks on the small pallet. They look like two square brackets facing each other. Those are the marks left by the mill. And if you look carefully, you can see the four bolt holes near the corners of the brackets.

View attachment 377525

Hope your delivery is like others that I have seen on the internet.