- Joined

- Jun 29, 2019

- Messages

- 63

Here is my journey, first I would like to thank everyone for this site and the wealth of information and sharing that happens here.

Special Thanks to:

Mark Jacobs

David Best

After many months of reading, researching and thought I reached out to Matt the end of Oct 2020 to have a few questions answered before I placed my order. Everything went well I thought, the only thing that was not doable was my request to have my machine built with a spider already in the spindle. Matt sent me an email with everything we spoke about and a few days later I spoke with John and mailed my 20% deposit check. Per Matt and John the shipment with my machine was expected to PM the week of Christmas.

I ordered some tooling while waiting and contacted John the week before Christmas and was told the machine is expected the week after Christmas. PM would email when it arrives but would not put it in line to have accessories installed before final payment received. Final payment mailed the next day. The arrival date again changed to Jan 10th and the ship actually made port in NY on Jan 13th. Container went thru customs and sat at the rail head for just over 2 weeks before moving to PA. I did receive an email late one evening that the machine had made it to PM (Nicole was working way to late), I also received an email with the Install slip showing the bin location of all accessories ordered with the exception of one item that I was aware might be late. I called the next day to confirm all was well and that everything I ordered was in fact there and allocated to me with the one exception and was told yes, we have your final payment, it will be placed in line to be built out and you will be notified before shipping. I was told that may take 2-3 weeks.

In the mean time I had received some measurements for the base as I needed to have risers built sine I'm a little on the tall side.

I get the call from Jeff at PM that my order was ready to ship with the exception of two items that would not be shipped with the machine. I inquired about this since my install slip showed the additional item in stock allocated to me and I provided the bin location and they were supposed to install this item ( taper attachment). I had ordered the taper attachment and paid the additional cost to have them install the magnetic DRO so to ensure no clearance issue with taper attachment and the DRO scale. Mind you my order has been paid complete since I was told before Christmas that no accessories would be installed and made ready for shipment until all funds received by PM. Had I known I would NOT have paid to have the DRO installed because my order specifically stated for the taper attachment to be installed by PM to make sure no clearance issues with the DRO scale. I have installed a 3 axis DRO from DRO PRO's on my Bridgeport and it went well.

The machine did ship the next day and went to Dayton OH and sat for three days waiting on dispatch then to Little Rock. I will say Jeff with PM did me a favor by offering and quoting me a price for inside delivery. I was expecting to have to pick it up at the terminal due to living some what rural. The driver was able to get down my driveway and with my help we got it into the garage just about 10ft from the door into the shop.

While on the pallet I removed the rear cover and all of the factory electronics, I installed Mark's control board and completed the re-wiring while it was easy to get to everything instead of waiting till it was in place. I used a lift strap and the hay fork on the tractor to lift it from the pallet. I have seen lets of folks using pipe to move their machine, while hanging from the lifting strap I tapped the machine base threads to 1/2-13 and screwed some casters and we pushed into my shop. Very easy job for 2 people even going over the shop door threshold.

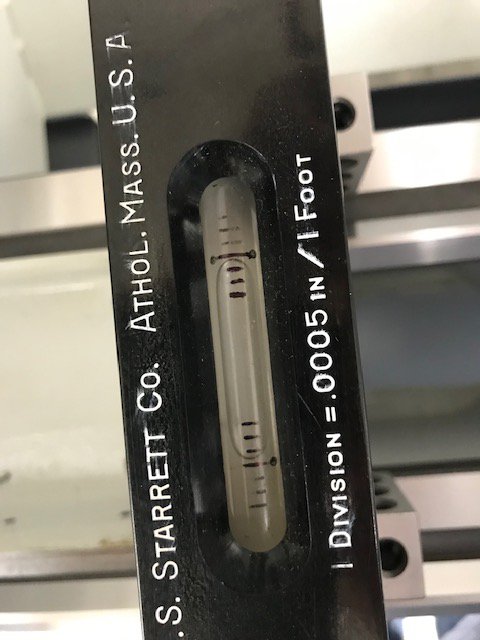

After we got it inside the shop I used my floor jack to take the pressure off the casters and install the risers. I finished up the wiring and set about getting it "level". The way are as parallel as I can it them using a Starrett 199.

A little more cleanup, mounting a few accessories. The bracket for the lamp was included, the holes for the bracket were already in the back cover but no bolts to be found anywhere. I did go ahead and order some Gates Tri-Power belts and put them on before first startup.

Spindle run out is as advertised. in checking both ground surfaces of the spindle they are easily under .0001 with my DTI.

A text or two with Mark and he was happy with my installation of his system and I was ready to test wreck it. No smoke, no sparks everything worked.

Break-in completed as recommended by PM, 10 minutes runtime in each gear.

So now I'm smiling and real happy about things.

I read several time Rollie's Dads method of alignment. I grabbed the inch diameter ground bar I got from Mcmaster Carr and put in the 3 jaw chuck that came with the machine. I set up my mag base and DTI and went thru the process, Hummmmmmmm something is not right here my measurements show the headstock is out of alignment by .0135. I took the chuck off and re-cleaned EVERYTHING and got the same measurement. I took the PM 3 jaw off and put the Bison 4 jaw on and re-indicated, same result. D@#it, what am I missing. Ok I also have a 1.250 ground baar from Mcmaster Carr, maybe something is wrong with the first one. Again same result over and over the headstock is out by .0135.

Just to be clear during all of this I was also re-checking the ways to ensure they were still parallel to each other and something hasn't moved.

I know this is long my apologizes, I had a 1.750 6061 piece of round stock and put it in the 4 jaw. I had it under .0005 runout at the headstock. Ok now we are getting somewhere run it out 9.5 inches and it's out by .012. At this point I'm confused and a little ****** at myself right.

I know, get the PM 4 way tool post off there and get my new Dorian QCTP I had hid and do some measurements. To the mill, take a little of here and a little off there and the T-Nut for the Dorian fits the machine perfectly. Grab a tool with a HSS insert, set it up on center and take a skim cut or three. DTI measurements and bam it's out .0125, cutting a taper. Loosen 6 bolts and then adjust the headstock (too far the first time of course). Several passes and adjustments later we have success. The headstock is now cutting a taper of .0003 over 9.5 inches. Ok that was a fluke? Take another pass to confirm and yep it's now down to .0003. So ladies and gents please ring in here, .0003 is ok. Call it good and move on cause I'm convinced if I keep chasing it I'll wind up frustrated.

Overall I am pleased and excited to get some time with the machine, I will be posting questions and things I run into looking for hep and suggestions.

A few things for anyone getting ready to go down this road or already on it. If you are thinking about doing the conversion the Mark has do it on the front end you will not regret it. I thought about waiting till "later" and it's got to be easier to just do it starting out when it's easier to get to everything and be done with it. The stock machine is basically a 12 speed straight cut gear transmission, converted I can go from any rpm from below 50 to above 2000 if needed and every RPM in between.

I really would like to have seen a QC sheet provided with the machine letting me know what was checked and what the results were and who signed off on this. I am not experienced enough to know for sure but from what I have read here and other places. I was prepared for the need to do the headstock alignment but I just can't seem understand or agree that shipping a machine out of alignment that much should happen. So maybe the sip hit an iceberg or the train ran over a cow or something and knocked it out a bit. As tight as the 6 bolts were I doubt that and a QC checklist prior to shipment would have shown this and prevented a lot of head scratching and cussing on my part.

Anyway a huge thanks to this forum, Mark Jacobs, David Best, JBOLT and everyone that has posted the things I read in preparation and during this journey.

FYI, I'm still waiting on the other 2 items, It's a new world and time I understand. The delays we all are going thru now are not anyone's fault really, it's just the way things are now.

First intended Projects:

Tool Height Gage

Spyder

Modify Gear Cover for Spyder

Special Thanks to:

Mark Jacobs

David Best

After many months of reading, researching and thought I reached out to Matt the end of Oct 2020 to have a few questions answered before I placed my order. Everything went well I thought, the only thing that was not doable was my request to have my machine built with a spider already in the spindle. Matt sent me an email with everything we spoke about and a few days later I spoke with John and mailed my 20% deposit check. Per Matt and John the shipment with my machine was expected to PM the week of Christmas.

I ordered some tooling while waiting and contacted John the week before Christmas and was told the machine is expected the week after Christmas. PM would email when it arrives but would not put it in line to have accessories installed before final payment received. Final payment mailed the next day. The arrival date again changed to Jan 10th and the ship actually made port in NY on Jan 13th. Container went thru customs and sat at the rail head for just over 2 weeks before moving to PA. I did receive an email late one evening that the machine had made it to PM (Nicole was working way to late), I also received an email with the Install slip showing the bin location of all accessories ordered with the exception of one item that I was aware might be late. I called the next day to confirm all was well and that everything I ordered was in fact there and allocated to me with the one exception and was told yes, we have your final payment, it will be placed in line to be built out and you will be notified before shipping. I was told that may take 2-3 weeks.

In the mean time I had received some measurements for the base as I needed to have risers built sine I'm a little on the tall side.

I get the call from Jeff at PM that my order was ready to ship with the exception of two items that would not be shipped with the machine. I inquired about this since my install slip showed the additional item in stock allocated to me and I provided the bin location and they were supposed to install this item ( taper attachment). I had ordered the taper attachment and paid the additional cost to have them install the magnetic DRO so to ensure no clearance issue with taper attachment and the DRO scale. Mind you my order has been paid complete since I was told before Christmas that no accessories would be installed and made ready for shipment until all funds received by PM. Had I known I would NOT have paid to have the DRO installed because my order specifically stated for the taper attachment to be installed by PM to make sure no clearance issues with the DRO scale. I have installed a 3 axis DRO from DRO PRO's on my Bridgeport and it went well.

The machine did ship the next day and went to Dayton OH and sat for three days waiting on dispatch then to Little Rock. I will say Jeff with PM did me a favor by offering and quoting me a price for inside delivery. I was expecting to have to pick it up at the terminal due to living some what rural. The driver was able to get down my driveway and with my help we got it into the garage just about 10ft from the door into the shop.

While on the pallet I removed the rear cover and all of the factory electronics, I installed Mark's control board and completed the re-wiring while it was easy to get to everything instead of waiting till it was in place. I used a lift strap and the hay fork on the tractor to lift it from the pallet. I have seen lets of folks using pipe to move their machine, while hanging from the lifting strap I tapped the machine base threads to 1/2-13 and screwed some casters and we pushed into my shop. Very easy job for 2 people even going over the shop door threshold.

After we got it inside the shop I used my floor jack to take the pressure off the casters and install the risers. I finished up the wiring and set about getting it "level". The way are as parallel as I can it them using a Starrett 199.

A little more cleanup, mounting a few accessories. The bracket for the lamp was included, the holes for the bracket were already in the back cover but no bolts to be found anywhere. I did go ahead and order some Gates Tri-Power belts and put them on before first startup.

Spindle run out is as advertised. in checking both ground surfaces of the spindle they are easily under .0001 with my DTI.

A text or two with Mark and he was happy with my installation of his system and I was ready to test wreck it. No smoke, no sparks everything worked.

Break-in completed as recommended by PM, 10 minutes runtime in each gear.

So now I'm smiling and real happy about things.

I read several time Rollie's Dads method of alignment. I grabbed the inch diameter ground bar I got from Mcmaster Carr and put in the 3 jaw chuck that came with the machine. I set up my mag base and DTI and went thru the process, Hummmmmmmm something is not right here my measurements show the headstock is out of alignment by .0135. I took the chuck off and re-cleaned EVERYTHING and got the same measurement. I took the PM 3 jaw off and put the Bison 4 jaw on and re-indicated, same result. D@#it, what am I missing. Ok I also have a 1.250 ground baar from Mcmaster Carr, maybe something is wrong with the first one. Again same result over and over the headstock is out by .0135.

Just to be clear during all of this I was also re-checking the ways to ensure they were still parallel to each other and something hasn't moved.

I know this is long my apologizes, I had a 1.750 6061 piece of round stock and put it in the 4 jaw. I had it under .0005 runout at the headstock. Ok now we are getting somewhere run it out 9.5 inches and it's out by .012. At this point I'm confused and a little ****** at myself right.

I know, get the PM 4 way tool post off there and get my new Dorian QCTP I had hid and do some measurements. To the mill, take a little of here and a little off there and the T-Nut for the Dorian fits the machine perfectly. Grab a tool with a HSS insert, set it up on center and take a skim cut or three. DTI measurements and bam it's out .0125, cutting a taper. Loosen 6 bolts and then adjust the headstock (too far the first time of course). Several passes and adjustments later we have success. The headstock is now cutting a taper of .0003 over 9.5 inches. Ok that was a fluke? Take another pass to confirm and yep it's now down to .0003. So ladies and gents please ring in here, .0003 is ok. Call it good and move on cause I'm convinced if I keep chasing it I'll wind up frustrated.

Overall I am pleased and excited to get some time with the machine, I will be posting questions and things I run into looking for hep and suggestions.

A few things for anyone getting ready to go down this road or already on it. If you are thinking about doing the conversion the Mark has do it on the front end you will not regret it. I thought about waiting till "later" and it's got to be easier to just do it starting out when it's easier to get to everything and be done with it. The stock machine is basically a 12 speed straight cut gear transmission, converted I can go from any rpm from below 50 to above 2000 if needed and every RPM in between.

I really would like to have seen a QC sheet provided with the machine letting me know what was checked and what the results were and who signed off on this. I am not experienced enough to know for sure but from what I have read here and other places. I was prepared for the need to do the headstock alignment but I just can't seem understand or agree that shipping a machine out of alignment that much should happen. So maybe the sip hit an iceberg or the train ran over a cow or something and knocked it out a bit. As tight as the 6 bolts were I doubt that and a QC checklist prior to shipment would have shown this and prevented a lot of head scratching and cussing on my part.

Anyway a huge thanks to this forum, Mark Jacobs, David Best, JBOLT and everyone that has posted the things I read in preparation and during this journey.

FYI, I'm still waiting on the other 2 items, It's a new world and time I understand. The delays we all are going thru now are not anyone's fault really, it's just the way things are now.

First intended Projects:

Tool Height Gage

Spyder

Modify Gear Cover for Spyder