After a year of looking I found one. While it may not be in the best condition as the other I looked at (visually) the owner was trust worthy and honest about everything. The machine was in a support role for the CNC's.

The only real issue I have, is that the quill gets tight around the 4" mark. I can lower it to 5 though. I took the quill out and notice chips in the bore of the quill casting and few small marks on the quill. Nothing I could fee but you can see it. I took the allen screw out to just make sure this wasn't causing any interference.

I'm at the point where do I want to tear it down and paint it, give her some youth back -or- just put it back together with the necessary parts.

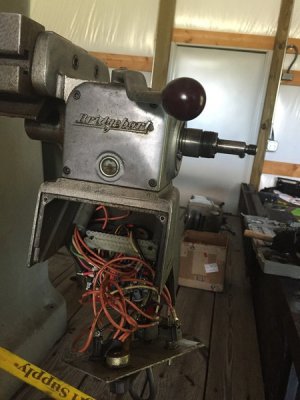

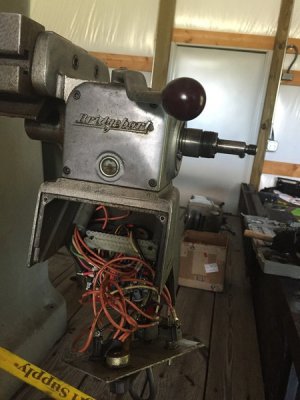

The power feed works, still trying to figure out model I have. The power feed does not like to go slow at all and I'm sure there is hardly any oil in the unit.. I just fired it up to see how it works and etc. It looks like the electrical components (at least the board) were replaced.

First got her home

Removing the quill. I used the bed to help catch the quill in case it fell. I only lower the table .200 or less each time.

There are two markings close to one another that are parallel. I'm curious if this is causing my stiffness when lowering the quill. After I cleaned the bore and the quill I sprayed some WD-40 and place the quill back in the quill I could tell that the over felt had improved but not still as smooth as others.

The unknown model powerfeed

The only real issue I have, is that the quill gets tight around the 4" mark. I can lower it to 5 though. I took the quill out and notice chips in the bore of the quill casting and few small marks on the quill. Nothing I could fee but you can see it. I took the allen screw out to just make sure this wasn't causing any interference.

I'm at the point where do I want to tear it down and paint it, give her some youth back -or- just put it back together with the necessary parts.

The power feed works, still trying to figure out model I have. The power feed does not like to go slow at all and I'm sure there is hardly any oil in the unit.. I just fired it up to see how it works and etc. It looks like the electrical components (at least the board) were replaced.

First got her home

Removing the quill. I used the bed to help catch the quill in case it fell. I only lower the table .200 or less each time.

There are two markings close to one another that are parallel. I'm curious if this is causing my stiffness when lowering the quill. After I cleaned the bore and the quill I sprayed some WD-40 and place the quill back in the quill I could tell that the over felt had improved but not still as smooth as others.

The unknown model powerfeed